Chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent and application method thereof

A technology of multi-component co-infiltration and application method, which is applied in the field of mold surface treatment, can solve the problems of high coating temperature, long time, poor wear resistance, etc., and achieve the effects of high coating quality, short production cycle and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of penetration agent (mass percentage): borax (70%), V 2 o 5 (6%), Cr 2 o 3 (8%), Al powder (6%), NaF (6%), Ce (4%).

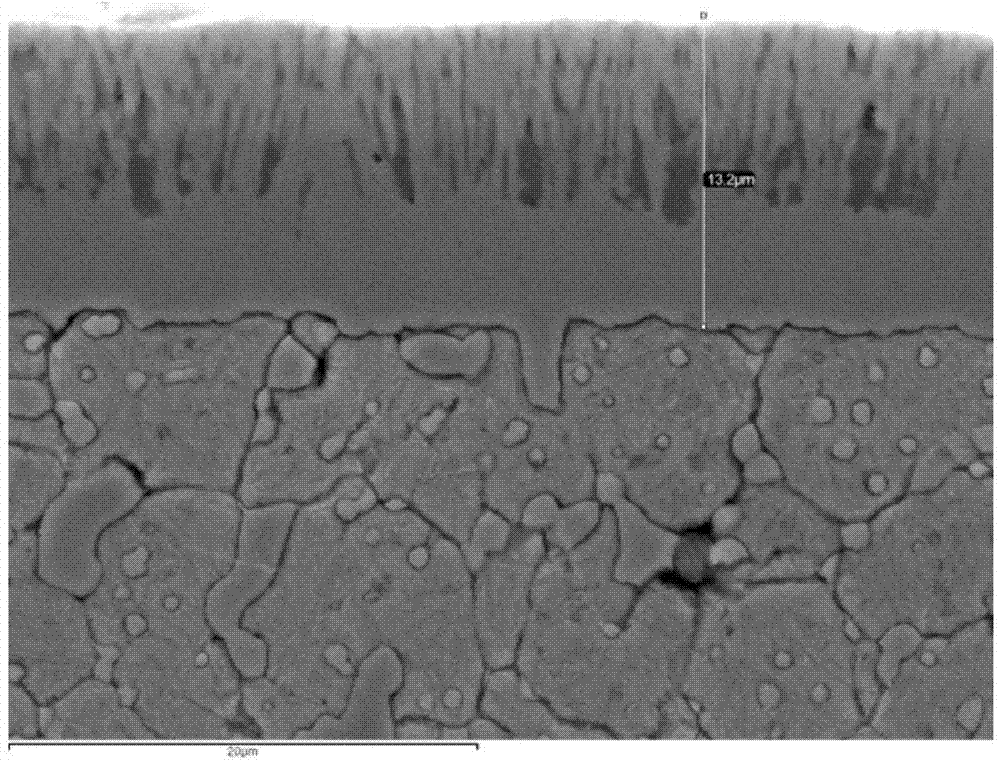

[0018] First melt borax in a crucible, then put other infiltrating agent components into fully reacted and melted evenly, at the same time preheat the Cr12 steel mold at a temperature of 400-450°C. Carry out TD treatment in the above penetration agent at a temperature of 940°C for 4 hours; directly oil quench after taking out, and temper for 2 hours at 180°C. After measurement, the average hardness of the mold surface is Hv 0.05 =2950, the thickness of the seepage layer is 13.2μm. The cross-sectional microstructure of the obtained cladding SEM secondary electron morphology see figure 1 .

Embodiment 2

[0020] Preparation of penetration agent (mass percentage): borax (70%), V 2 o 5 (6%), Cr 2 o 3 (7%), Si-Ca (6%), NaF (6%), Ce-Fe (5%).

[0021] First melt borax in the crucible, then put other infiltrating agent components into fully react and melt evenly, and preheat the Cr12MoV steel mold at the same time, the temperature is 400-450°C. Carry out TD treatment in the above penetration agent at a temperature of 940°C for 4 hours; directly oil quench after taking out, and temper at 180°C for 2 hours. After measurement, the average hardness of the mold surface is Hv 0.05 =2850, the thickness of the seepage layer is 12.6μm.

Embodiment 3

[0023] Preparation of penetration agent (mass percentage): borax (72%), V 2 o 5 (6%), Cr 2 o 3 (9%), Si-Ca (5%), NaF (5%), Ce-Fe (3%).

[0024] Preheat the Cr12MoV steel mold at a temperature of 400-450°C. Carry out TD treatment in the above penetrating agent at a temperature of 920°C for 6 hours; directly oil quench after taking out, and temper at 180°C for 2 hours. After measurement, the average hardness of the mold surface is Hv 0.05 =2750, the thickness of the seepage layer is 10.6μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeable layer thickness | aaaaa | aaaaa |

| Permeable layer thickness | aaaaa | aaaaa |

| Permeable layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com