Ti-Nb-O memory alloy having high recoverable strain and preparation method thereof

A memory alloy and alloy technology, which is applied in the field of Ti-Nb-O memory alloy and its preparation, can solve the problems of high production cost, reduce the elastic modulus of the alloy, complicated processes, etc., achieve low production cost, reduce the elastic modulus, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Pure Ti powder, Nb powder, TiO 2 Powder and TiH 2 According to the ratio of Ti atoms, Nb atoms, O atoms and H atoms to 86:11:1:2, the powder is mixed evenly by ball milling method. The purity of the powder used is 99.5%, and the particle size is 48-75 μm; Press molding in air, the molding pressure is 600MPa, the temperature is 30°C, and the time is 5 minutes to obtain a green body;

[0032] (2) Put the green body obtained in step (1) into a sintering furnace, and sinter it under vacuum. The sintering temperature is 1400°C, and the sintering time is 10 hours to obtain a sintered Ti-Nb-O alloy, which is analyzed by chemical composition. The atomic ratio of Ti:Nb:O is 88:11:1;

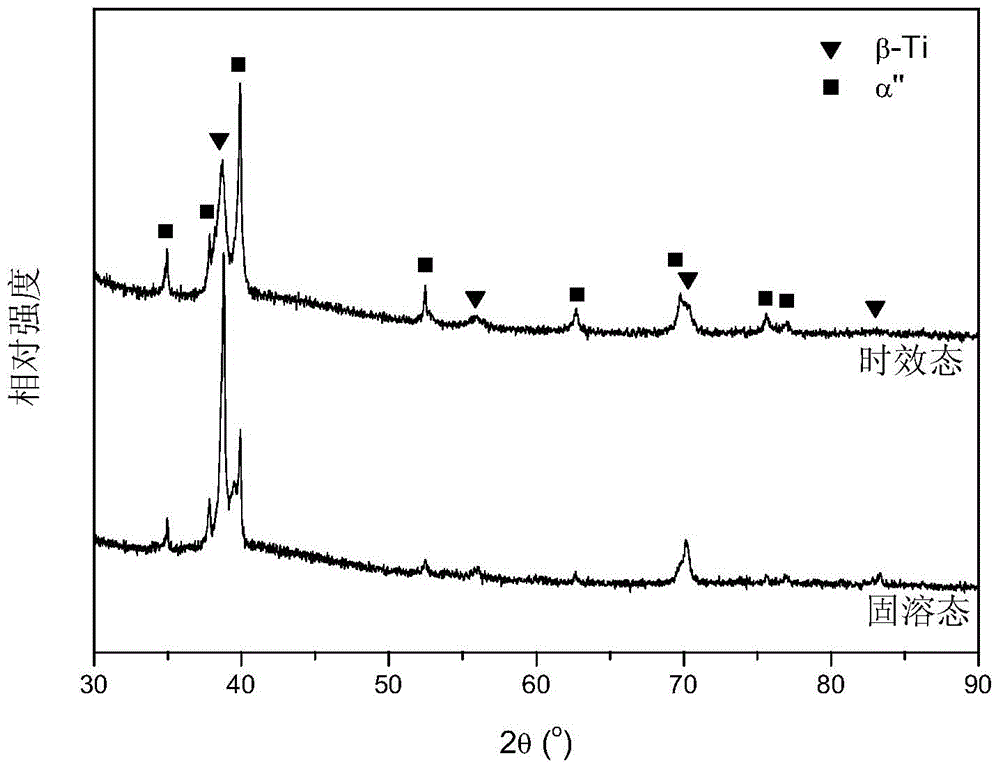

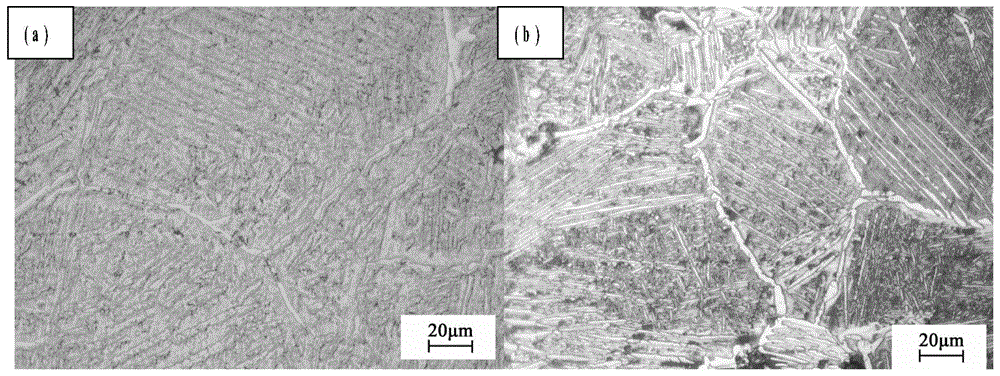

[0033] (3) Put the sintered Ti-Nb-O alloy obtained in step (2) into a tube furnace, and carry out solid solution treatment under the protection of argon. Rapid cooling in ice water to obtain solid solution Ti-Nb-O memory alloy;

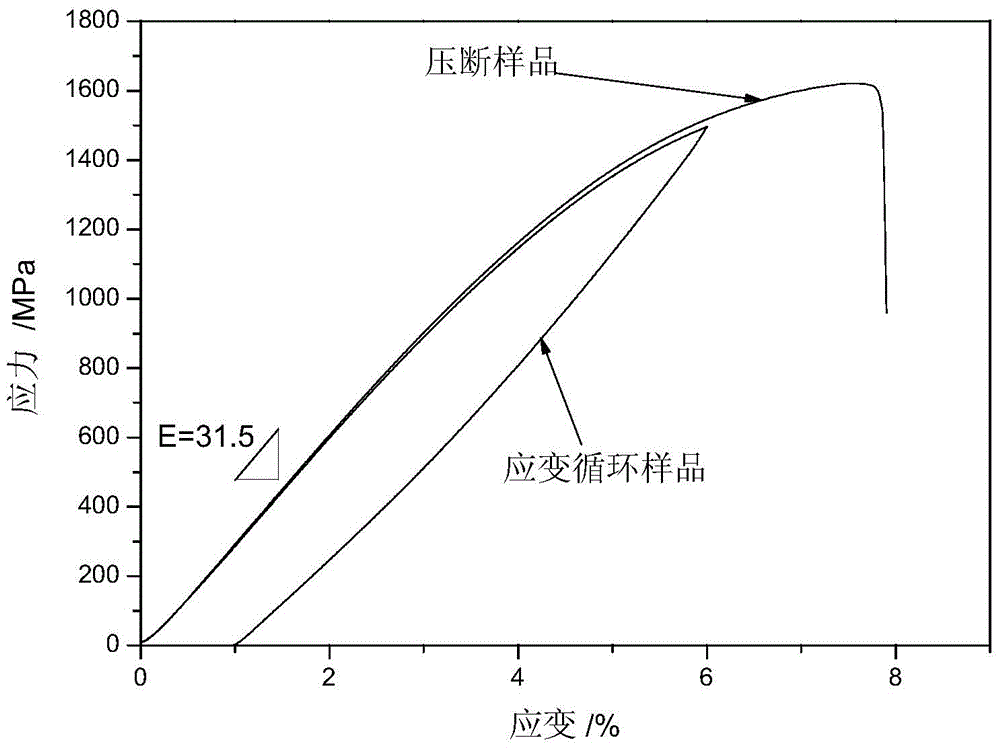

[0034] (4) Put the Ti-Nb-O memory alloy in solid solution sta...

Embodiment 2

[0040] (1) Pure Ti powder, Nb powder, TiO 2 Powder and TiH 2 The powder is uniformly mixed according to the ratio of Ti atoms, Nb atoms, O atoms and H atoms in the ratio of 88:11:0:0. The purity of the powder used is 99.5%, and the particle size is 48-75 μm; The powder is compressed in air, the molding pressure is 600MPa, the temperature is 100°C, and the time is 10 minutes to obtain a green body;

[0041] (2) Put the green body obtained in step (1) into a low-pressure sintering furnace, and sinter it under the protection of argon. The atomic ratio of :Nb:O is 88:10.7:1.3;

[0042] (3) Put the sintered Ti-Nb-O alloy obtained in step (2) into a tube furnace, and carry out solid solution treatment under the protection of argon. Cool to ice water to obtain solid solution Ti-Nb-O memory alloy;

[0043] (4) Put the Ti-Nb-O memory alloy in solid solution state obtained in step (3) into a tube furnace, and perform aging treatment under the protection of argon. The aging temperatu...

Embodiment 3

[0046] (1) Pure Ti powder, Nb powder, TiO 2 Powder and TiH 2 According to the ratio of Ti atoms, Nb atoms, O atoms and H atoms to 83:15:2:0, the powder is mixed evenly by ball milling method. The purity of the powder used is 99.5%, and the particle size is 48-75 μm; Press molding in air, the molding pressure is 400MPa, the temperature is 50°C, and the time is 15 minutes to obtain the alloy green body;

[0047] (2) Put the green body obtained in step (1) into a hot isostatic pressing furnace, and sinter it under the protection of argon. The sintering temperature is 1300°C, and the sintering time is 16 hours to obtain a sintered Ti-Nb-O alloy. The atomic ratio of Ti:Nb:O is 84:13.5:2.5;

[0048] (3) Put the sintered Ti-Nb-O alloy obtained in step (2) into a tube furnace, and carry out solid solution treatment under the protection of argon. The solid solution temperature is 900°C, and the solid solution time is 5 hours. Cooling into ice water to obtain high recoverable strain,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com