Unsaturated polyester glass fiber cloth laminated board and preparation method thereof

A technology of polyester glass fiber and glass fiber cloth, which is applied in the field of layered products and their preparation, can solve the problems of inability to meet technical performance requirements, low mechanical strength of glass fiber molding plates, etc., and achieves easy industrial expansion of production and mechanical strength. High, stable product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

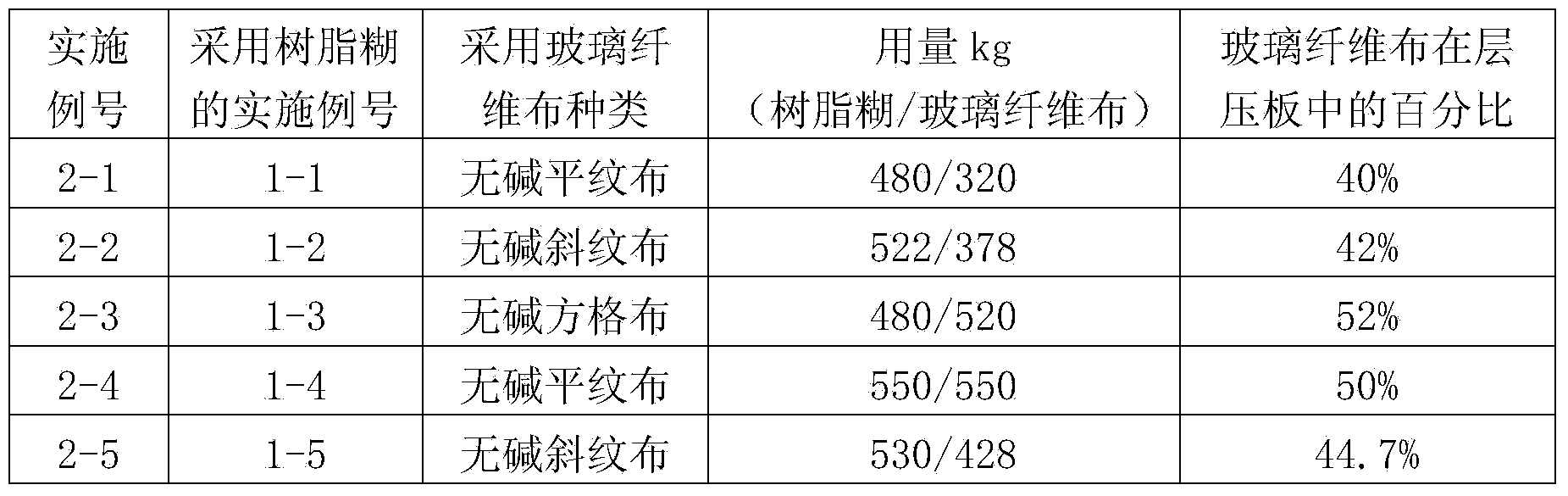

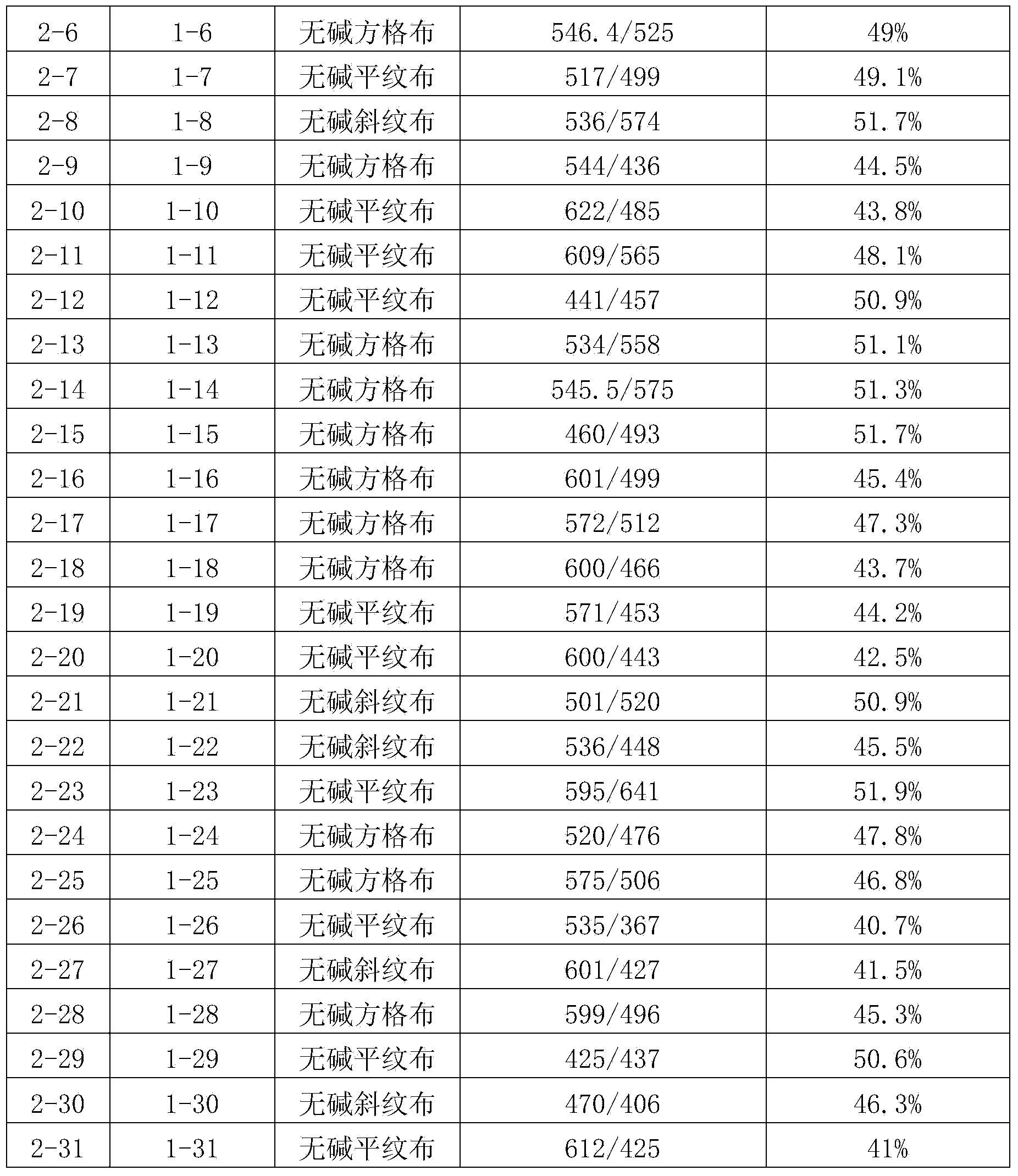

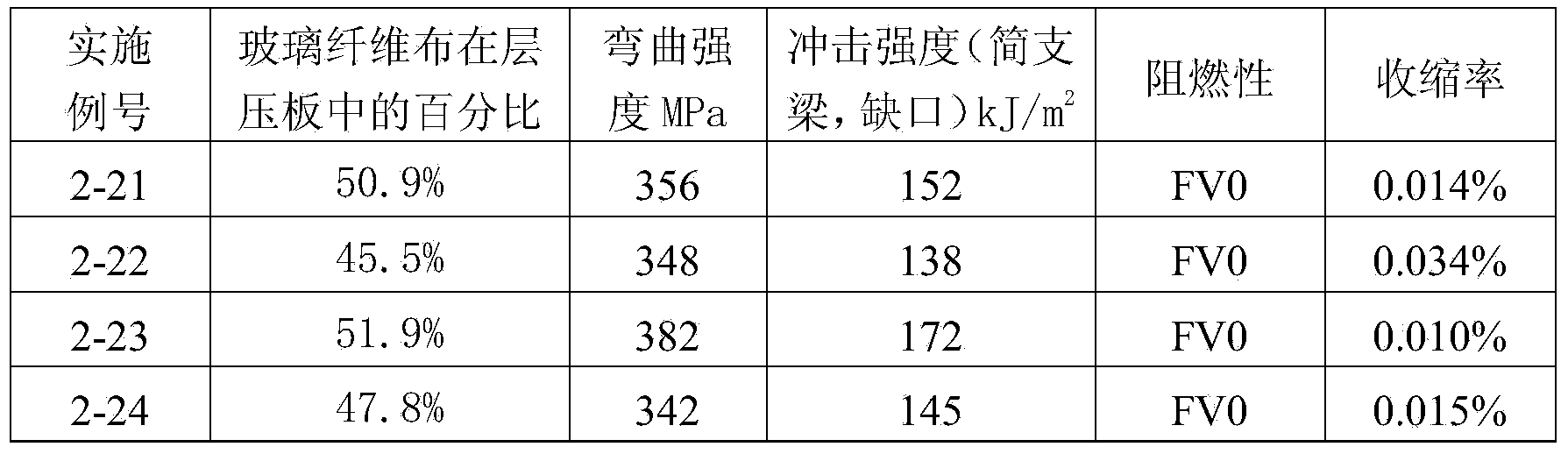

Examples

Embodiment 1-1

[0047] Mix 162kg of 67% styrene solution of thickened dicyclopentadiene modified unsaturated polyester resin, 30kg of styrene solution of 70% saturated polyester resin with a viscosity of 600-1000mPa·S, 20kg of 40% poly Styrene solution of vinyl acetate, 320kg of aluminum hydroxide, 2kg of active magnesium oxide, 2.3kg of benzopinacol silyl ether, 10kg of titanium dioxide pigment paste, and 10kg of zinc stearate are put into a mixing tank at room temperature High-speed stirring for 10 minutes was mixed with 556.3kg resin paste.

Embodiment 1-2

[0049] Mix 162kg of 70% styrene solution of dicyclopentadiene modified unsaturated polyester resin, 60kg of styrene solution of 70% saturated polyester resin with a viscosity of 600-1000mPa·S, 30kg of 40% poly Styrene solution of vinyl acetate, 360kg of aluminum hydroxide, 3.5kg of activated magnesium oxide, 2.4kg of benzopinacol silyl ether, 12kg of titanium dioxide pigment paste, and 11kg of zinc stearate are put into the mixing tank at room temperature Under high-speed stirring for 10 minutes, 640.9kg resin paste was prepared.

Embodiment 1-3

[0051] 162kg of styrene solution of 68% thickening dicyclopentadiene modified unsaturated polyester resin, 40kg of styrene solution of 70% saturated polyester resin with a viscosity of 600-1000mPa·S, 40kg of 40% poly Styrene solution of vinyl acetate, 280kg of aluminum hydroxide, 2.5kg of activated magnesium oxide, 2.8kg of initiator (benzopinacol silyl ether: benzoyl tert-butyl peroxide = 1:3), 20kg Titanium dioxide pigment paste, 13kg of zinc stearate dropped into the mixing tank at room temperature and stirred at high speed for 10 minutes to be mixed with 560.3kg resin paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com