A kind of backplane for metal perforated solar cell and preparation method thereof

A technology of solar cells and metal perforation, applied in the field of solar back sheets, can solve the problems of waste of fluororesin film, increase product cost, high price, etc., and achieve the effects of high cross-linking density, improved service life, and improved protective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

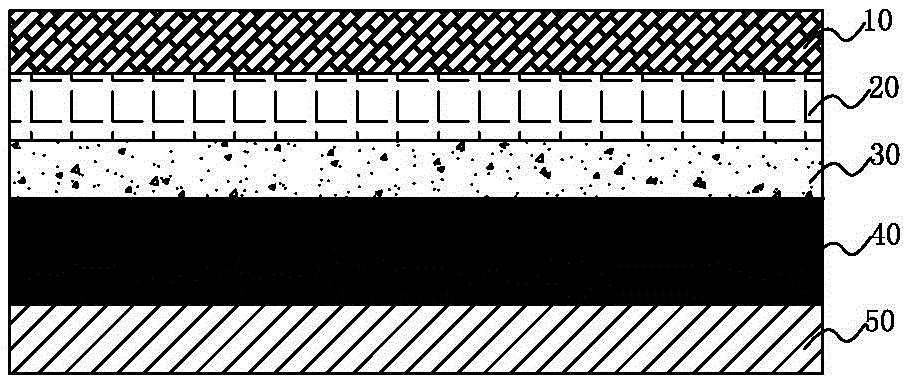

[0031] A back sheet for metal perforated solar cells, which sequentially includes an insulating layer, a metal layer, an adhesive layer, a base material layer, and a weather-resistant layer, and the weather-resistant layer is coated on the base material layer by a coating device. The weather-resistant layer It is a fluorine-containing resin composition, and the fluorine-containing resin composition includes:

[0032] Modified fluororesin 46%;

[0033] Fumed silica 4%;

[0034] Titanium dioxide 15%;

[0035] Curing agent 5%;

[0036] Butyl ester 30%.

[0037] The modified fluororesin is a vinylidene fluoride copolymer modified with two groups of carboxylic acid group and hydroxyl group.

[0038] The curing agent is polyisocyanate.

[0039] The substrate layer is polyethylene terephthalate.

[0040] The bonding layer is epoxy resin adhesive.

[0041] The metal layer is copper foil.

[0042] The insulating layer is epoxy resin ink coated on the metal layer by screen print...

Embodiment 2

[0050] A back sheet for metal perforated solar cells, which sequentially includes an insulating layer, a metal layer, an adhesive layer, a base material layer, and a weather-resistant layer, and the weather-resistant layer is coated on the base material layer by a coating device. The weather-resistant layer It is a fluorine-containing resin composition, and the fluorine-containing resin composition includes:

[0051] Modified fluororesin 25%;

[0052] Fumed silica 2%;

[0053] Titanium dioxide 20%;

[0054] Curing agent 8%;

[0055] Butyl ester 45%.

[0056] The modified fluororesin is a hexafluoropropylene homopolymer modified with carboxylic acid groups.

[0057] The curing agent is hydrogenated diphenylmethane diisocyanate.

[0058] The substrate layer is polybutylene terephthalate.

[0059] The bonding layer is a saturated polyester adhesive.

[0060] The metal layer is aluminum foil.

[0061] The insulating layer is polyester resin ink coated on the metal layer by...

Embodiment 3

[0069]A back sheet for metal perforated solar cells, which sequentially includes an insulating layer, a metal layer, an adhesive layer, a base material layer, and a weather-resistant layer, and the weather-resistant layer is coated on the base material layer by a coating device. The weather-resistant layer It is a fluorine-containing resin composition, and the fluorine-containing resin composition includes:

[0070] Modified fluororesin 35%;

[0071] Fumed silica 3%;

[0072] Titanium dioxide 25%;

[0073] Curing agent 5%;

[0074] Butyl esters 32%.

[0075] The modified fluororesin is tetrafluoroethylene homopolymer modified with aziridine group.

[0076] The curing agent is hexamethylene diisocyanate.

[0077] The substrate layer is polyethylene naphthalate.

[0078] The bonding layer is polyurethane adhesive.

[0079] The metal layer is copper foil.

[0080] The insulating layer is epoxy resin ink, polyester resin ink or acrylic resin ink coated on the metal layer b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com