Production method of 50-micron ultrathin chips

A production method and technology for ultra-thin chips, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to reduce resistance, reduce chip cracks and chipping, and ensure processing capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

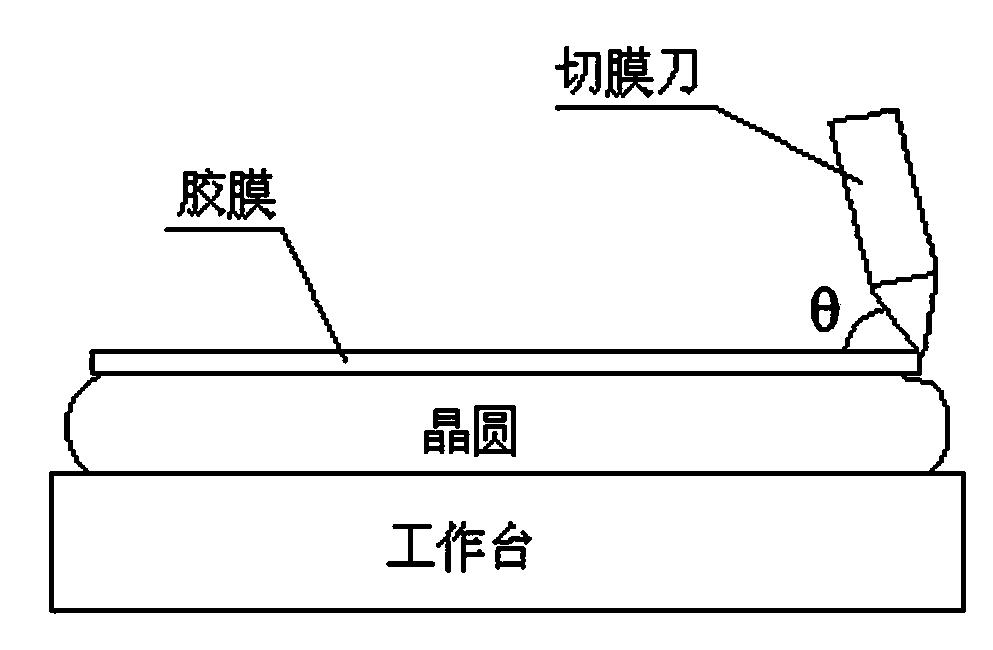

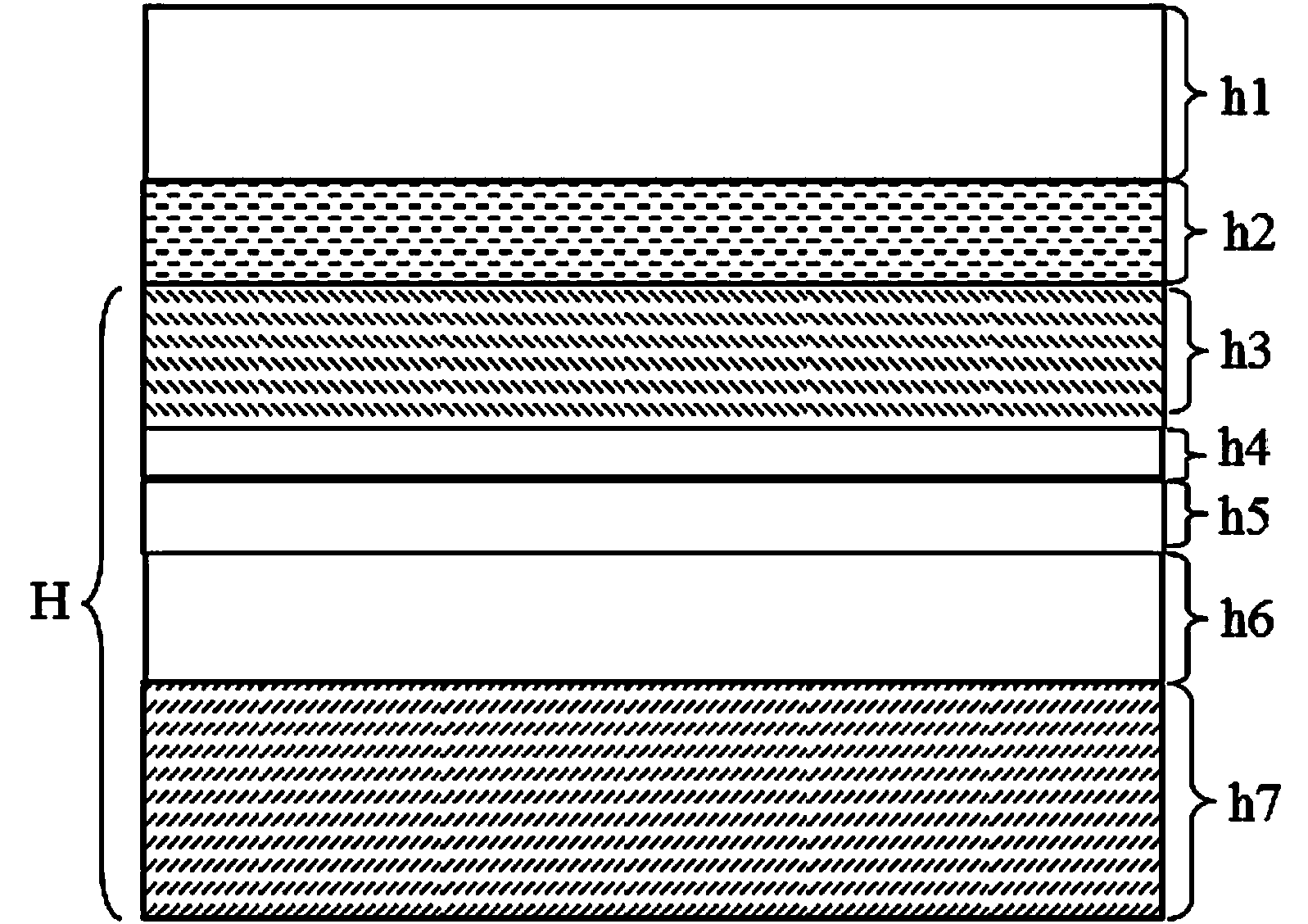

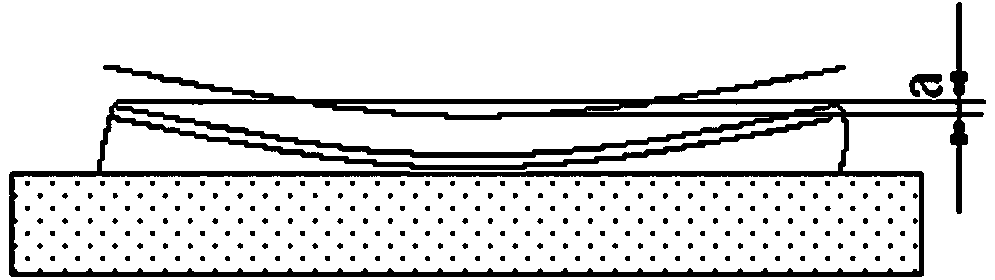

[0048] Paste semiconductor-specific UV adhesive film on the surface of the wafer graphics; according to the shape of the wafer positioning edge, set the corresponding blade running track parameters and film cutting speed to ensure that the running track of the film cutting blade changes with the different positioning sides, and the whole After cutting the wafer, the film cutting track matches the shape of the wafer edge. The cutting speed of the film cutting is 10mm / sec. When the number of film (wafer) cut by the film cutting knife reaches 1000pcs, replace the film cutting knife; the film cutting knife between the film cutting knife and the wafer surface when cutting the film The angle θ is 65°; a fully automatic thinning machine capable of thinning 12-inch ultra-thin wafers (50μm) is adopted. First, automatic feeding, positioning, and then thinning. The thinning process is divided into three stages. First coarse grinding, then fine grinding;

[0049]The rough grinding range ...

Embodiment 2

[0051] Paste semiconductor-specific UV adhesive film on the surface of the wafer graphics; according to the shape of the wafer positioning edge, set the corresponding blade running track parameters and film cutting speed to ensure that the running track of the film cutting blade changes with the different positioning sides, and the whole After cutting the wafer, the film cutting track matches the shape of the wafer edge. The cutting speed of the film cutting is 30mm / sec. When the number of film (wafer) cut by the film cutting knife reaches 1000pcs, replace the film cutting knife; the film cutting knife between the film cutting knife and the wafer surface when cutting the film The angle θ is 90°; a fully automatic thinning machine capable of thinning 12-inch ultra-thin wafers (50μm) is adopted. First, the material is automatically loaded, positioned, and then thinned. The thinning process is divided into three stages. First coarse grinding, then fine grinding;

[0052] The rou...

Embodiment 3

[0054] Paste semiconductor-specific UV adhesive film on the surface of the wafer graphics; according to the shape of the wafer positioning edge, set the corresponding blade running track parameters and film cutting speed to ensure that the running track of the film cutting blade changes with the different positioning sides, and the whole After cutting the wafer, the film cutting track matches the shape of the wafer edge. The cutting speed of the film cutting is 20mm / sec. When the number of film (wafer) cut by the film cutting knife reaches 1000pcs, replace the film cutting knife; the film cutting knife between the film cutting knife and the wafer surface when cutting the film The angle θ is 80°; a fully automatic thinning machine capable of thinning 12-inch ultra-thin wafers (50μm) is adopted. First, the material is automatically loaded, positioned, and then thinned. The thinning process is divided into three stages. First coarse grinding, then fine grinding;

[0055] The rou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blade thickness | aaaaa | aaaaa |

| Blade thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com