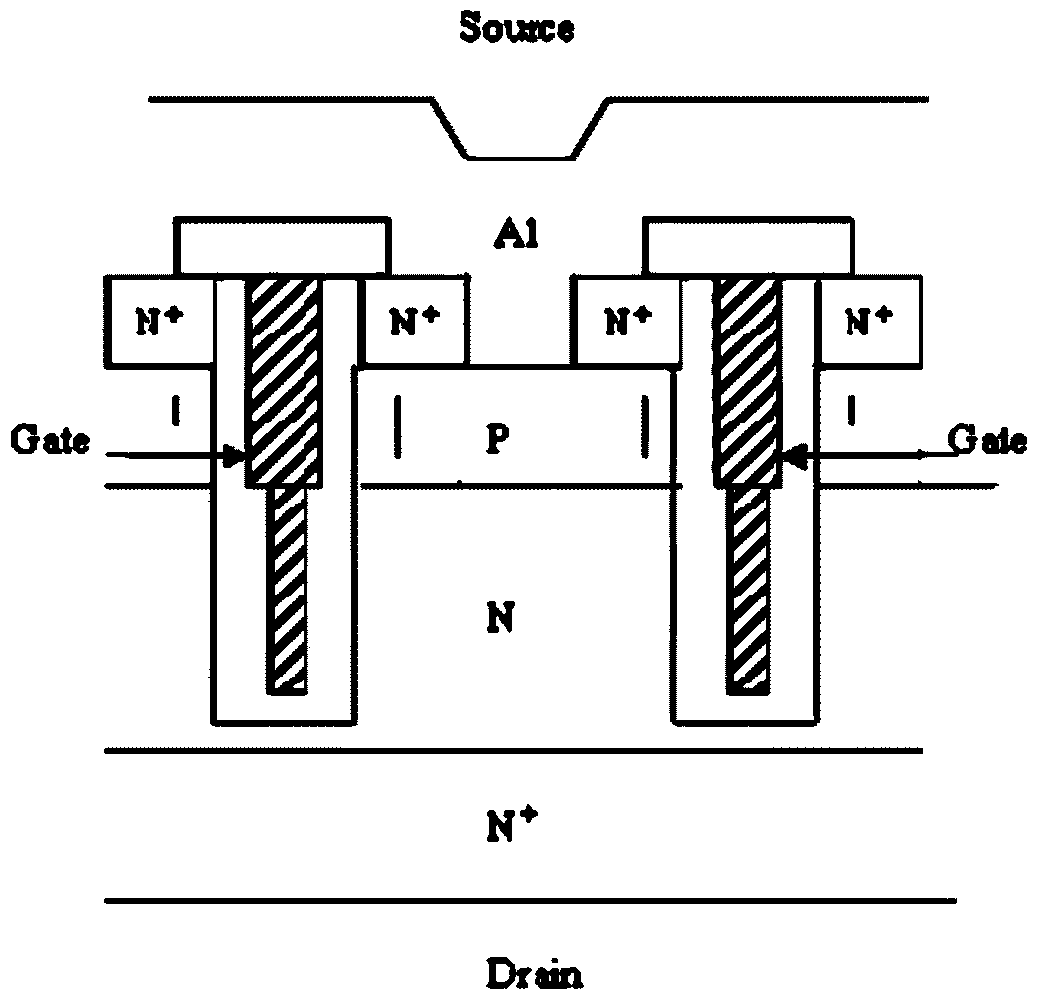

Channel voltage dividing field effect tube and production method based on high-energy ion implantation mode

A high-energy ion, field effect tube technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult production technology and process, and achieve the effect of eliminating capacitance, improving switching speed, and increasing doping concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for producing a channel pressure-dividing field-effect transistor based on high-energy ion implantation, characterized in that it includes the following steps:

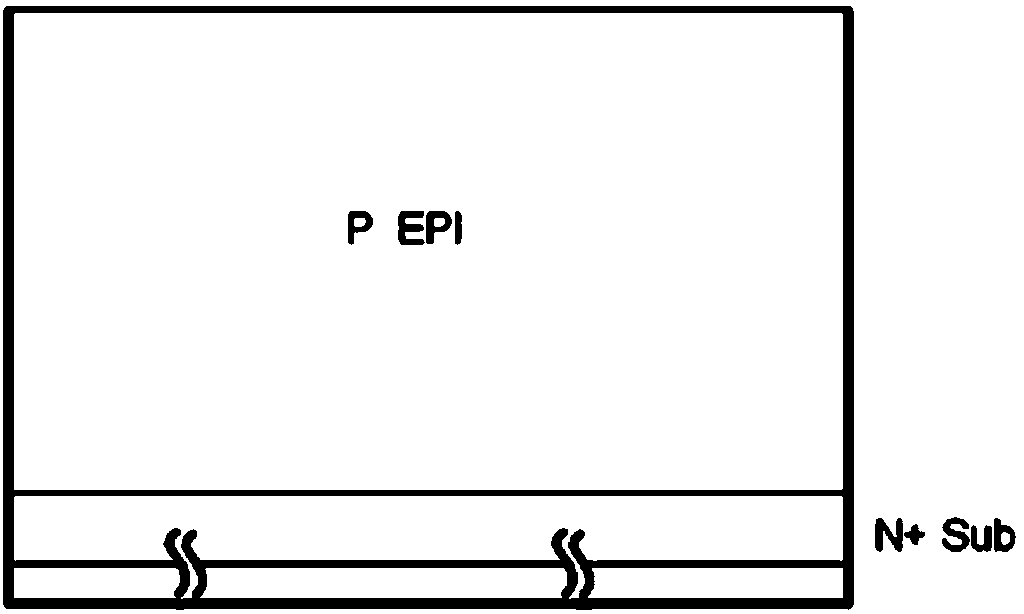

[0027] (1) growing a P-type epitaxial layer 5 on an N+ substrate 4; see figure 2 ;

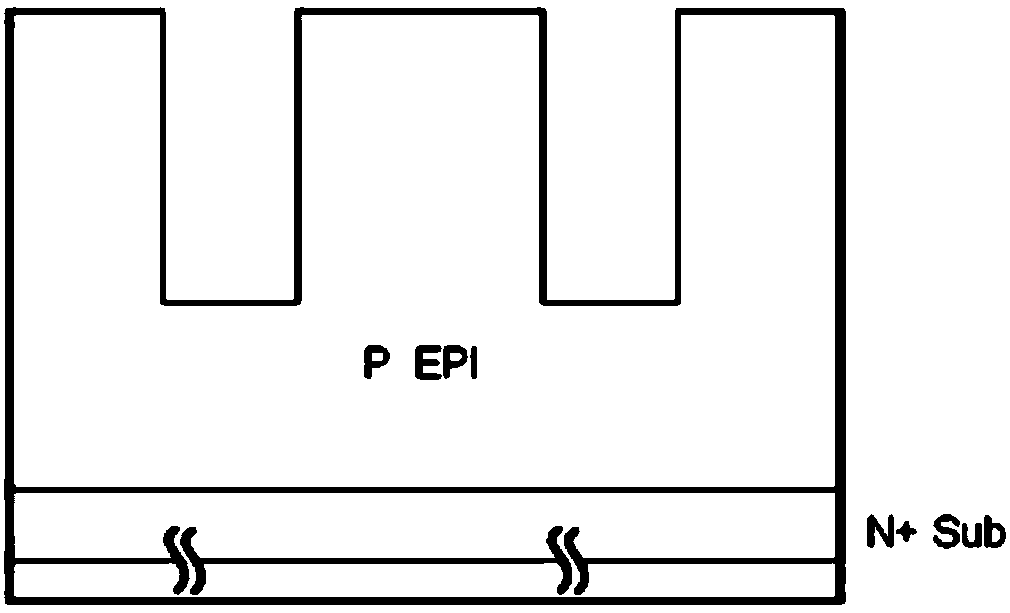

[0028] (2) Photoetching strip-shaped grooves on the P-type epitaxial layer 5 grown in step (1); see image 3 ; Among them, the photolithography stripe pattern is as Figure 3a shown;

[0029] (3) growing a silicon dioxide oxide layer on the groove wall, groove bottom, and the upper surface of the P-type epitaxial layer 5 obtained in step (2); see Figure 4 ;

[0030] (4) Deposit metal or polysilicon in the strip-shaped trench obtained in step (3) as a good conductor 8, and connect them together outside the functional area to form a gate 2; see Figure 5 ;

[0031] (5) Diffusion downward from the surface of the crystal obtained in step (4) to push the junction to form an n-region, see Figure 6 ;

[0032] (6) D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com