High-efficiency and heat-insulation color steel compound plate

A technology of composite panels and color steel plates, which is applied to roofs, building components, and roof coverings using flat/curved panels. , to achieve the effect of enhancing noise reduction and heat insulation, significant anti-corrosion effect, and thin weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

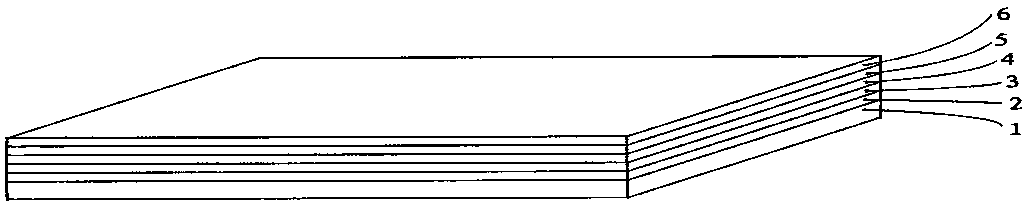

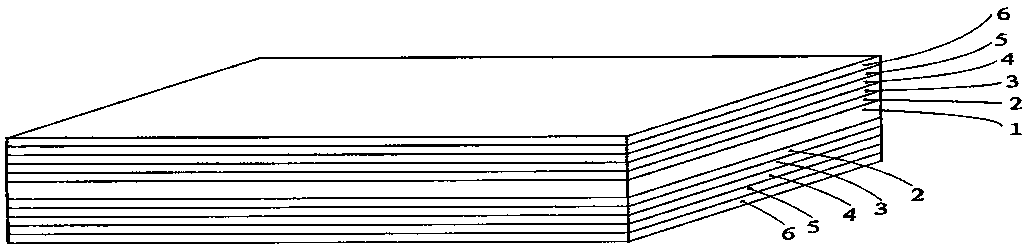

[0014] Such as figure 1 As shown, the high-efficiency heat-insulating color steel composite panel of the present invention uses color steel plate or color aluminum plate as the substrate, and its technical scheme is: a non-woven fabric layer 2, an aluminum foil layer 5 and a PET composite layer are sequentially bonded on the outer surface of the substrate 1. The film layer 6 has embossing on the outermost PET film layer. The embossing on the PET lamination layer is concave-convex.

[0015] There are also PE coating and PE film layers between the non-woven fabric layer and the aluminum foil layer to make the layers of this product more firmly bonded. The test proves that this structure is not easy to peel off and delaminate even in the extremely low temperature cold zone; And enhance the noise reduction and heat insulation effect.

[0016] The high-efficiency heat-insulating color-steel composite board of the present invention has remarkable effects of heat insulation, sound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com