Method for smelting titanium aluminum base alloy

A technology of base alloy and titanium-aluminum, applied in the smelting field of titanium-aluminum-base alloy, can solve the problems of segregation, element residue, hot cracking, etc., and achieve the effect of low hydrogen cost, short time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

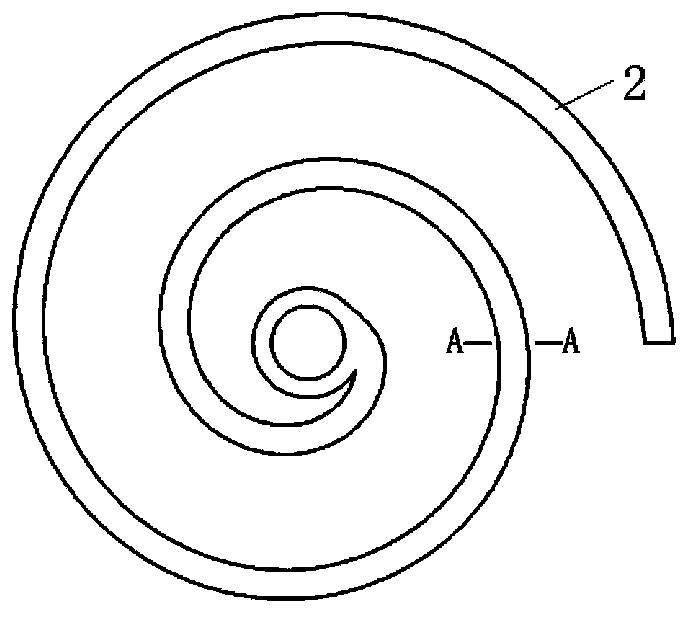

Image

Examples

Embodiment 1

[0030] Vacuumize the non-consumable arc melting furnace to 6×10 -3 Pa, and then feed hydrogen, wherein the partial pressure of hydrogen is 5kPa.

[0031] The titanium-aluminum-based alloy melt is smelted four times: for the first time, 260g of sponge titanium and 130g of pure aluminum are used for smelting, and the titanium-aluminum-based alloy melt is cooled to become an alloy ingot; after the alloy ingot is turned over, Carry out the second smelting, wait for the titanium-aluminum-based alloy melt to cool to become a secondary alloy ingot; after turning over the alloy ingot, perform the third smelting, wait for the titanium-aluminum-based alloy melt to cool to become a tertiary alloy ingot; After turning over the alloy ingot for the third time, the fourth smelting is carried out to obtain a titanium-aluminum-based alloy melt to be cast with uniform composition and superheat. The arc current is gradually increased for each smelting, the maximum arc current is 1300A, and the ...

Embodiment 2

[0034] Vacuumize the non-consumable arc melting furnace alloy melting furnace to 6×10 -3 Pa, then pass into hydrogen, pass into argon while passing into hydrogen, wherein the partial pressure of hydrogen is 10kPa, the partial pressure of argon is 20kPa, and the purity of argon is 99.999%.

[0035] The titanium-aluminum-based alloy melt is smelted four times: for the first time, 260g of sponge titanium and 130g of pure aluminum are used for smelting, and the titanium-aluminum-based alloy melt is cooled to become an alloy ingot; after the alloy ingot is turned over, Carry out the second smelting, wait for the titanium-aluminum-based alloy melt to cool to become a secondary alloy ingot; after turning over the alloy ingot, perform the third smelting, wait for the titanium-aluminum-based alloy melt to cool to become a tertiary alloy ingot; After turning over the alloy ingot for the third time, the fourth smelting is carried out to obtain a titanium-aluminum-based alloy melt to be c...

Embodiment 3

[0038] It includes the step of melting the alloy and the step of introducing hydrogen:

[0039] Alloy melting step: In a water-cooled crucible induction melting furnace, vacuumize to 6×10 -3 Pa, and then directly start smelting titanium-aluminum-based alloys, the raw materials for smelting are 260g sponge titanium and 130g pure aluminum. After the raw materials are completely melted, they are kept warm for 5 minutes to obtain a titanium-aluminum-based alloy melt with uniform composition and superheat.

[0040] The step of feeding hydrogen: vacuumize the water-cooled crucible induction melting furnace to 6×10 -3 Pa, then feed hydrogen, continue smelting the obtained titanium-aluminum-based alloy melt, make hydrogen react with the titanium-aluminum-based alloy melt, feed the partial pressure of hydrogen to be 5kPa, feed the smelting time after hydrogen is 2 minutes, obtain Titanium-aluminum-based alloy melt to be poured.

[0041] After the smelting is completed and the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com