Lithium ion battery and multi-element positive material thereof as well as preparation method of multi-element positive material

A technology of lithium ion battery and positive electrode material, which is applied in the field of positive electrode material of multi-element lithium ion battery and its preparation, can solve the problem that the coating element is not closely combined with the surface of the material, the high voltage and high temperature performance of the material is affected, and the surface crystallization of the ternary material is damaged. and other problems, to achieve the effect of reducing Li/Ni mixing, improving conductivity, and superior high voltage and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

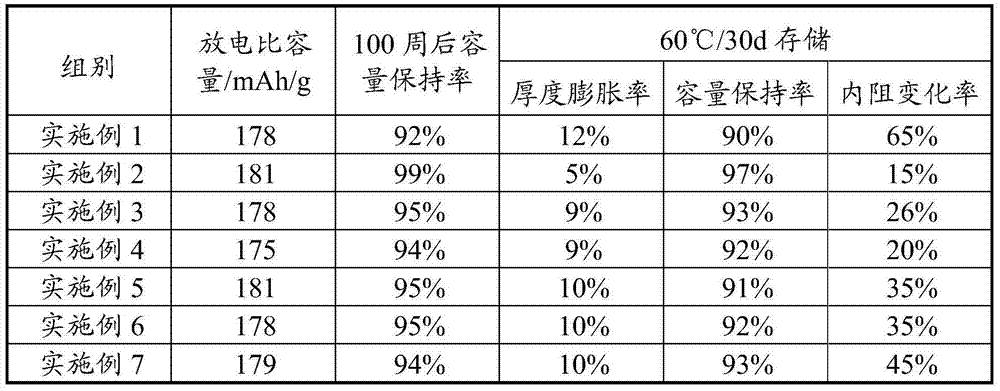

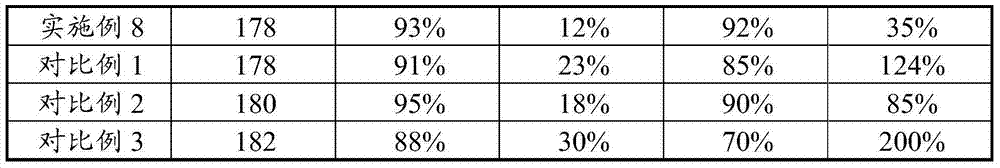

Examples

Embodiment 1

[0033] (1) Preparation of nickel-cobalt-manganese hydroxide precursor: use pure water as the bottom liquid, raise the temperature to 60°C-75°C, control the stirring speed at 160r / min-180r / min, add ammonia water to adjust the pH value of the bottom liquid to 10.3 About; the nickel-cobalt-manganese mixed salt solution with a total ion concentration of 60g / L, the sodium hydroxide solution with a concentration of 30wt.%, and the ammonia water with a concentration of 18vol.% are continuously pumped into the bottom liquid in parallel, and the nickel salt is nickel sulfate. , the cobalt salt is cobalt sulfate, the manganese salt is manganese sulfate, and the obtained reaction solution is configured; precipitation reaction occurs at 60°C to 75°C, and the solid content of the slurry in the reaction system is controlled to be 260g / L to 300g / L, and kept The above alkalinity and pH value, the reaction feed liquid continuously flows out from the upper overflow port of the reaction kettle an...

Embodiment 2

[0039] The difference from Example 1 is that in step (2) nickel-cobalt-manganese hydroxide is subjected to Ti surface doping treatment, the Ti surface doping amount is 0.5mol%, the modification temperature / time is 500°C / 5h, step (4 ) The treatment temperature / time in the surface Mg treatment of nickel-cobalt-manganese ternary material B is 850°C / 5h, step (5) nickel-cobalt-manganese ternary material Al 2 o 3 The treatment temperature / time in the coating treatment is 500°C / 5h; other raw materials, steps and parameters are the same as in Example 1. The molecular formula of the modified ternary material D is Li 1.05 Ni 0.495 co 0.195 mn 0.295 Ti 0.005 Mg 0.005 Al 0.005 o 2 (I CP measurement), the thickness of the magnesium-containing transition layer is 0.8-1.5 μm.

Embodiment 3

[0041] The difference from Example 1 is that in step (2) nickel-cobalt-manganese hydroxide is subjected to Ti surface doping treatment, the Ti surface doping amount is 2mol%, the modification temperature / time is 500°C / 5h, step (4) In the surface Mg treatment of nickel-cobalt-manganese ternary material B, the Mg modification treatment temperature / time is 800°C / 5h, step (5) nickel-cobalt-manganese ternary material Al 2 o 3 The treatment temperature / time in the coating treatment is 500°C / 5h; other raw materials, steps and parameters are the same as in Example 1. The theoretical chemical formula of material D is Li 1.05 Ni 0.485 co 0.19 mn 0.295 Ti 0.02 Mg 0.005 Al 0.005 o 2 (ICP test analysis), the thickness of the magnesium-containing transition layer is 0.6-1.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com