High-temperature chain lubricant and preparation method thereof

A technology for high-temperature chains and lubricants, which is applied in lubricating compositions, additives, and the petroleum industry. It can solve the problems of low flash point, inability to guarantee the normal use of high-temperature chain lubricants, and poor low-temperature performance, and achieve excellent lubrication and extreme pressure. Anti-wear properties, excellent rust resistance and water resistance, effects of excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

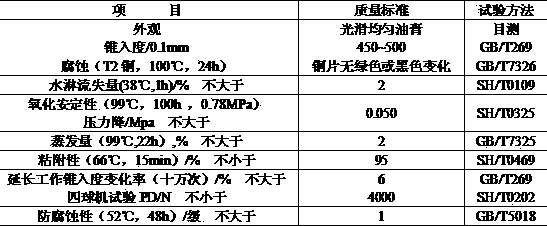

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention are described below to facilitate the understanding of those skilled in the art.

[0021] A high-temperature chain lubricant, the raw material components of the lubricant are in parts by weight: 70-90 parts of base oil, 10-20 parts of calcium petroleum sulfonate, 0.1-0.3 parts of ethanol, 0.4-0.8 parts of petroleum ether, 1-2 parts of fatty acid, 0.4-0.8 part of boric acid, 0.6-1 part of water, 1-2 parts of calcium hydroxide, 0.5-1 part of calcium carbonate, 0.2-0.5 part of high-temperature antioxidant, and the base oil is polyol Ester synthetic oil, the high temperature antioxidant is lauryl selenium.

[0022] A kind of preparation method of high temperature chain lubricant, described preparation method specifically comprises the following steps:

[0023] First, add 30 kilograms of polyol ester synthetic oil in the reactor, heat up, when the temperature is 45-55 ° C, add 10 kilograms of petroleum calcium sulfonate, 0.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com