Cold mix epoxy resin material for quickly repairing epoxy asphalt pavement pits as well as preparation method and application thereof

A cold-mix epoxy resin and epoxy asphalt technology, which is applied to the coagulation pavement, buildings, roads and other directions of on-site paving, can solve the problem of developing into pits, affecting the normal use of bridges, and epoxy asphalt pavement. The lack of maintenance materials and other problems can achieve the effect of good waterproof performance, short open traffic time and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

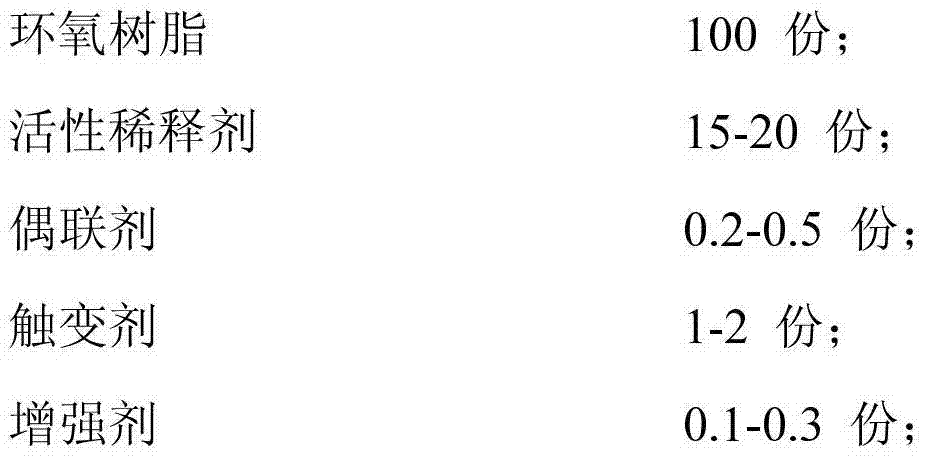

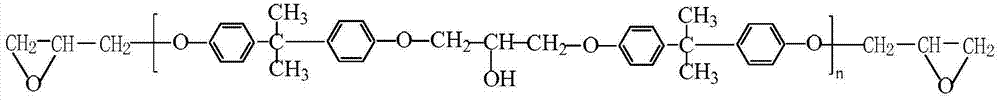

[0049] Example 1: Weigh 100 parts (parts by mass, the same below) bisphenol A glycidyl ether epoxy resin (E51) (provided by Wuxi Bluestar Petrochemical Co., Ltd.), add 10 parts of allyl glycidyl ether (Wuxi Bluestar Petrochemical Co., Ltd.), 5 parts of glycerol triglycidyl ether (provided by Wuxi Bluestar Petrochemical Co., Ltd.), 0.2 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane ( KH-560) (provided by Nanjing Yudeheng Fine Chemical Co., Ltd.), 1 part of oil-soluble fumed silica (provided by Degussa, Germany), 0.1 part of carbon black (N660) (provided by Cabot Corporation of the United States), heating to 60°C, stirred for 1 hour, and cooled to room temperature to obtain component A of the cold-mix epoxy resin material for rapid repair of potholes in epoxy asphalt pavement layers.

Embodiment 2

[0050] Example 2: Weigh 100 parts of bisphenol A glycidyl ether epoxy resin (E51), add 10 parts of allyl glycidyl ether, 10 parts of glycerol triglycidyl ether, 0.2 parts of γ-(3,4 Epoxycyclohexane) ethyltrimethoxysilane (KH-530) (provided by Nanjing Wanda Silicon Industry Co., Ltd.), 1 part of oil-soluble fumed silica, 0.2 part of carbon black (N660), heated to 60 ° C, stirred After cooling to room temperature for 1 hour, component A of the cold-mix epoxy resin material for rapid repair of potholes in epoxy asphalt pavement was obtained.

Embodiment 3

[0051] Example 3: Weigh 100 parts of bisphenol A glycidyl ether epoxy resin (E51), add 5 parts of allyl glycidyl ether, 10 parts of glycerol triglycidyl ether, 0.5 parts of γ-(2,3 Glycidyloxy) propyltrimethoxysilane (KH-560), 2 parts of organically modified attapulgite (provided by Jiangsu Dianjinshi Attapulgite Research and Development Co., Ltd.), 0.3 parts of carbon black (N660), heated to 60 ℃, stirred for 1 hour, and cooled to room temperature to obtain component A of the cold-mix epoxy resin material for rapid repair of epoxy asphalt pavement potholes.

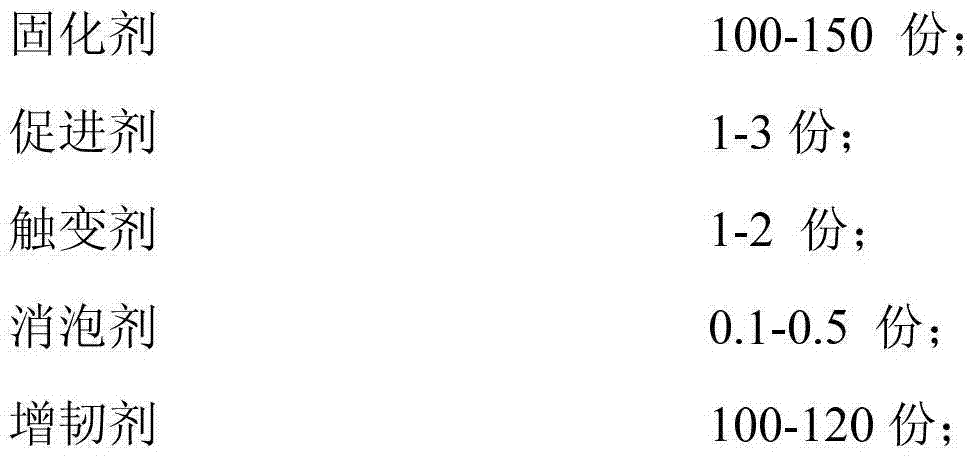

[0052] The preparation method of component B of cold mix epoxy resin material is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com