Carbon fiber composite material product and preparation method thereof

A composite material and carbon fiber technology, applied in the field of composite materials, can solve problems such as poor surface gloss of composite materials, achieve good apparent quality, reduce surface tension gradient, and improve surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

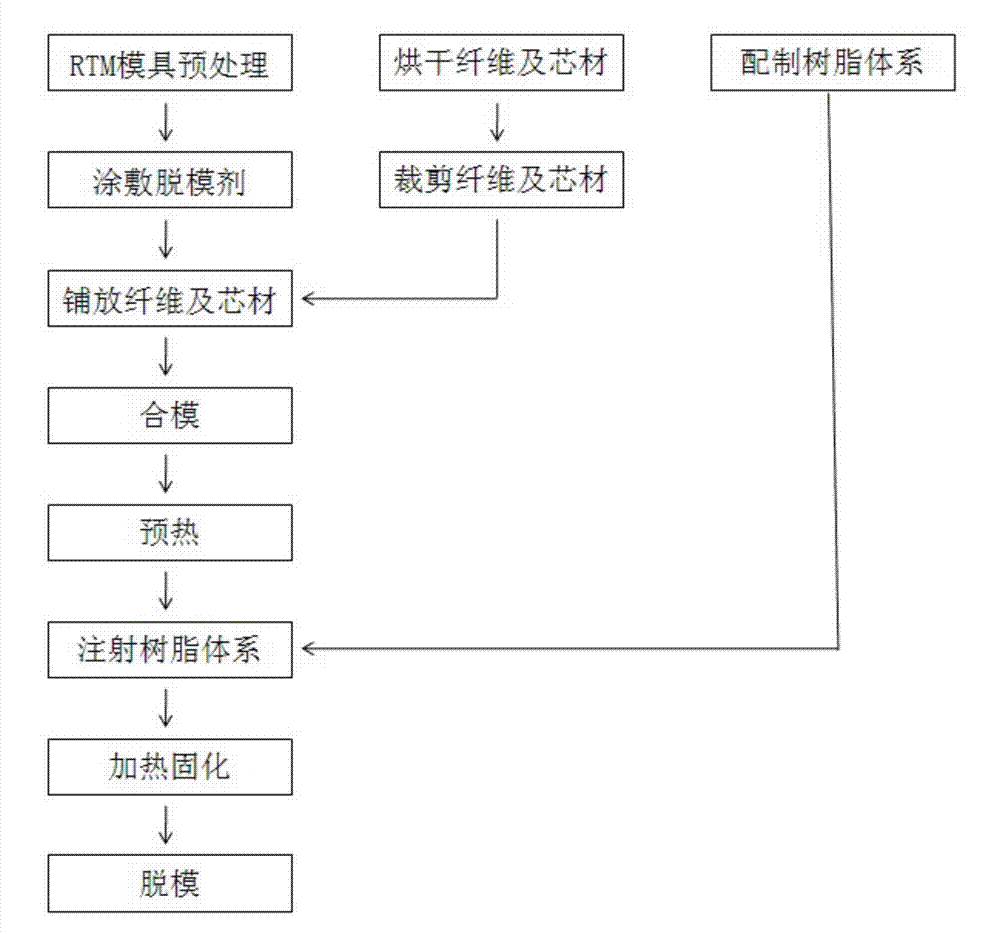

[0028] as attached figure 1 As shown, the embodiment of the present invention provides a high-gloss surface RTM molding foam sandwich carbon fiber reinforced resin composite product, and the high gloss surface RTM molding foam sandwich carbon fiber reinforced resin composite product includes the following components in volume fraction: 30% - 60% carbon fiber reinforcement, 5%-15% foam core and 35%-65% epoxy resin system including epoxy resin curing system and leveling agent. Specifically, preferably, the carbon fiber reinforcement is at least one of carbon fiber plain weave fabric, carbon fiber twill weave fabric, carbon fiber satin weave fabric, carbon fiber unidirectional fabric, carbon fiber multiaxial warp knitted fabric, and the foam core material is polyurethane At least one of foam material, polyvinyl chloride foam material and polymethacrylimide foam material.

[0029] Due to its high strength, high thermal shock resistance, low specific gravity, heat resistance and c...

Embodiment 2

[0039] as attached figure 1 As shown, the embodiment of the present invention provides a method for preparing a carbon fiber composite product, specifically as follows:

[0040] First, clean the RTM mold of auto parts products and spray the release agent, then lay the carbon fiber reinforcement and foam core material in the mold according to the set layer sequence, close the mold, and pre-heat at a certain temperature. Heat for a period of time (the preheating temperature and time are determined by the specific epoxy resin system) and then heat up the RTM mold with carbon fiber reinforcement and foam core material, and put a certain proportion of epoxy resin, curing agent and fluid The leveling agent is injected into the mold, wherein the pressure of the injection muzzle is kept below 2bar, and the final foam sandwich carbon fiber reinforced resin composite auto parts product is obtained after the above epoxy resin system is cured.

[0041] The volume proportions of the carbo...

Embodiment 3

[0056] as attached figure 1 As shown, the embodiment of the present invention provides a carbon fiber composite material product and its preparation method, specifically as follows:

[0057] Step 1: Clean the RTM mold of auto parts with ethanol. After the ethanol on the surface of the mold is completely volatilized, apply the release agent evenly on the surface of the cleaned RTM mold, leave it for 10 minutes, and repeatedly apply the release agent 3 times;

[0058] Step 2: Cut the dried carbon fiber plain weave fabric and polyurethane foam material according to the surface size of the RTM mold, and place the carbon fiber plain weave fabric with a volume ratio of 30%, 15% polyurethane foam material and carbon fiber plain weave fabric in sequence On the surface of the RTM mold, preheat at a set preheating temperature of 50°C for 5 minutes after mold closing, wherein the number of layers of the carbon fiber reinforced body is 5 layers;

[0059] Step 3: Prepare bisphenol A epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com