Method for preparing N-methylol group-D,L-calcium methionine microelement chelates by means of saponification liquid produced through D,L- methionine

A technology of trace elements and trace metal elements, which is applied in the field of chemical industry, can solve the problems of high production cost, poor stability, and low product purity, and achieve the effect of shortening the production cycle and large cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

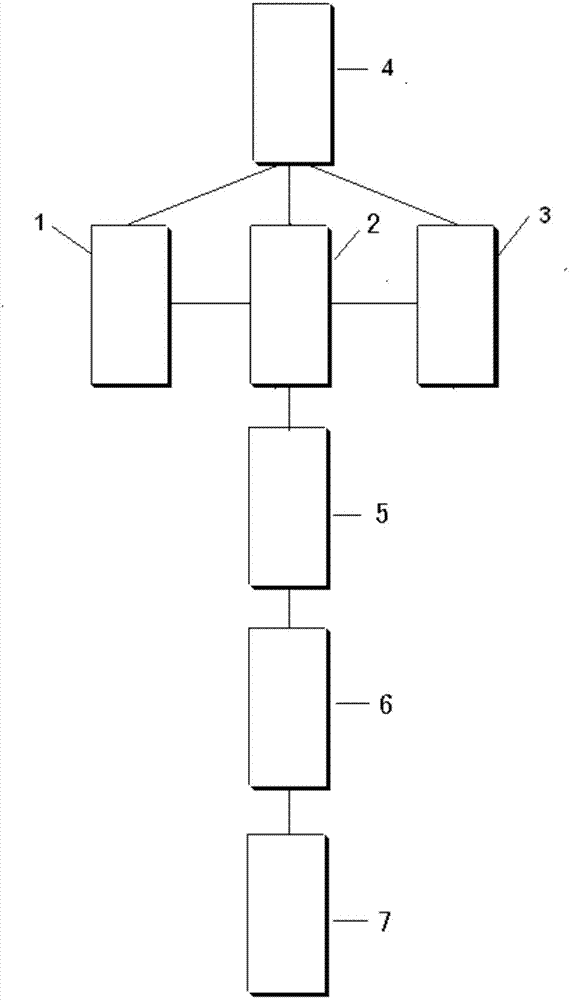

Method used

Image

Examples

Embodiment 1

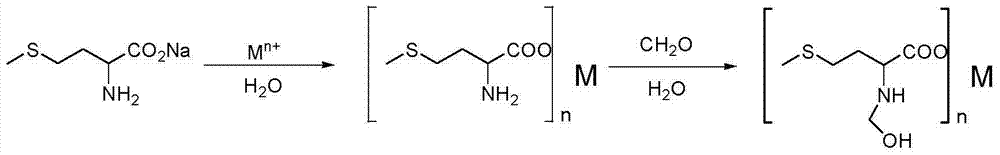

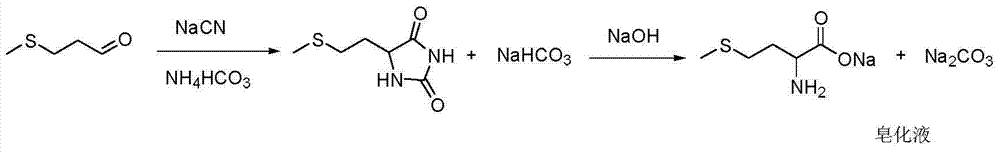

[0036] Embodiment 1 D, L-methionine produces saponification liquid

[0037] Mix 99.5% 3-methylthiopropanal with 30% sodium cyanide aqueous solution, then add ammonium bicarbonate aqueous solution, heat to 120°C in a closed manner, and react for 20 minutes to obtain 5-(2-methylthioethyl)- Hydantoin, decolorize the 5-(2-methylthioethyl)-hydantoin with activated carbon, add sodium hydroxide for hydrolysis, and heat the hydrolysis reaction system to 130°C to 165°C until fully hydrolyzed. Obtain a saponified solution. The saponified liquid obtained by hydrolysis can be directly used in the following examples to produce N-methylol-D, L-methionine trace element chelate after being decolorized by activated carbon. Analyze the composition of the saponified solution, which consists of the following components: D, L-methionine sodium in mass percentages of 17% ± 2%, sodium carbonate in mass percentages of 11% ± 2%, and the balance being water.

[0038] 5-(2-Methylthioethyl)-hydantoin c...

Embodiment 2

[0039] Embodiment 2 N-hydroxymethyl-D, the preparation of L-methionine zinc

[0040] Get the D after the decolorization that embodiment 1 mentions, L-methionine produces 1140 grams of saponification liquid, analyze the composition of saponification liquid: D, the mass percentage composition of L-methionine sodium is 15%, and the mass percentage composition of sodium carbonate is 10% %, the balance is water.

[0041] Add 253.1 grams (1.87mol) of anhydrous zinc chloride in batches to the above-mentioned saponified solution after decolorization, heat to 90°C, keep the reaction temperature at 90°C, react for 1 hour, filter the insoluble zinc carbonate, and cool the filtrate to At 0°C, a white precipitate was obtained, which was filtered to obtain a white D, L-methionine zinc solid.

[0042] Add the D, L-methionine zinc solid obtained above to 1 times the mass of water, stir, add 100 g (1.0 mol) of 30% formaldehyde solution to the D, L-methionine zinc slurry, keep the temperature ...

Embodiment 3

[0043] Embodiment 3 N-hydroxymethyl-D, the preparation of L-methionine ferrous

[0044] Get the saponification liquid 1140 grams after the decolouring mentioned in embodiment 1, analyze the composition of saponification liquid: D, the mass percentage composition of L-sodium methionine is 15%, and the mass percentage composition of sodium carbonate is 10%, and surplus is water .

[0045] Add 352.8 grams (1.80 mol) of ferrous chloride tetrahydrate to the above-mentioned saponified solution after decolorization, heat to 90°C, protect with nitrogen, keep the reaction temperature at 90°C, react for 1 hour, filter the insoluble matter, and cool the filtrate to 0 °C, a brown precipitate was obtained, which was filtered to obtain a brown ferrous D, L-methionine solid.

[0046] Add 1 times the quality of water to the ferrous D,L-methionine solid obtained above, stir, add 100 grams (1.0mol) of 30% formaldehyde solution to the ferrous D,L-methionine slurry, keep the temperature at 20°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com