Chromium zirconium mullite refractory material and preparation method thereof

A refractory material, zircon mullite technology, applied in the field of refractory materials, can solve problems such as spalling, brick body erosion, block falling, etc., and achieve the effect of excellent thermal shock resistance and high temperature slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

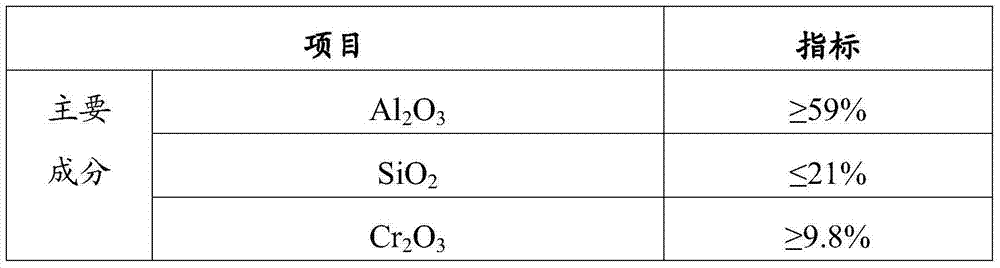

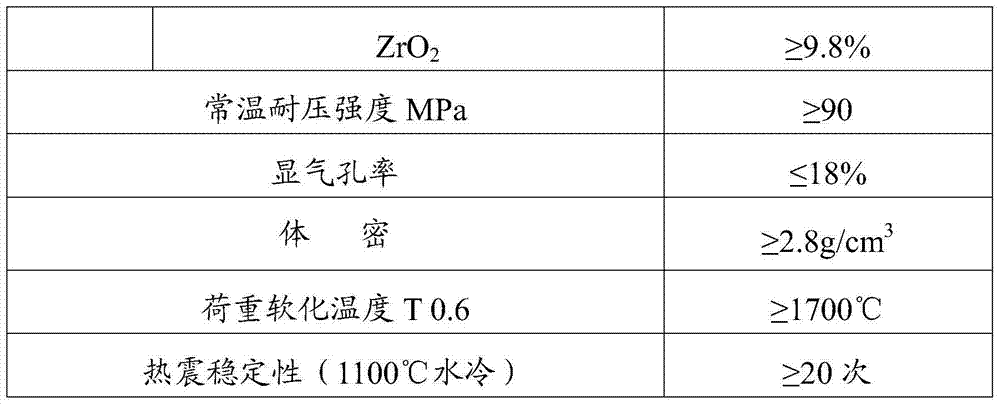

[0016] A chromium-zirconium mullite refractory material. The chromium-zirconium mullite refractory material uses fused mullite or sintered mullite as the aggregate, and uses zircon powder, corundum powder, and chromium oxide green as the matrix part of the product. The weight ratio of refractory raw materials is 65% mullite, 10% corundum powder, 15% zircon powder, and 10% chromium oxide green.

[0017] The mullite contains Al 2 o 3 74.5%, SiO 2 25% mullite, the corundum powder ≤ 325 mesh, Al 2 o 3 ≥99%, the zircon powder ≤325 mesh, ZrO 2 ≥65%, the chromium oxide green ≤325 mesh, CrO 2 ≥99%.

[0018] A preparation method of the refractory material, according to the above formula design, after mixing all the raw materials in a wet mill or a mixer, add about 3% of the pulp liquid as a binder, and mix the material for 8 hours , or directly shape it with a press. After the brick is dried, it is fired at a high temperature of about 1650 ° C for 4 hours.

[0019] The physical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com