Homogeneous network growth web Growth epitaxy method on sic substrate

A substrate and mesh technology, which is applied in the field of homogeneous mesh growth and epitaxy of silicon carbide SiC substrate, can solve problems such as the influence of SiC device performance, and achieve the effect of increasing the film growth area and shortening the epitaxy time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

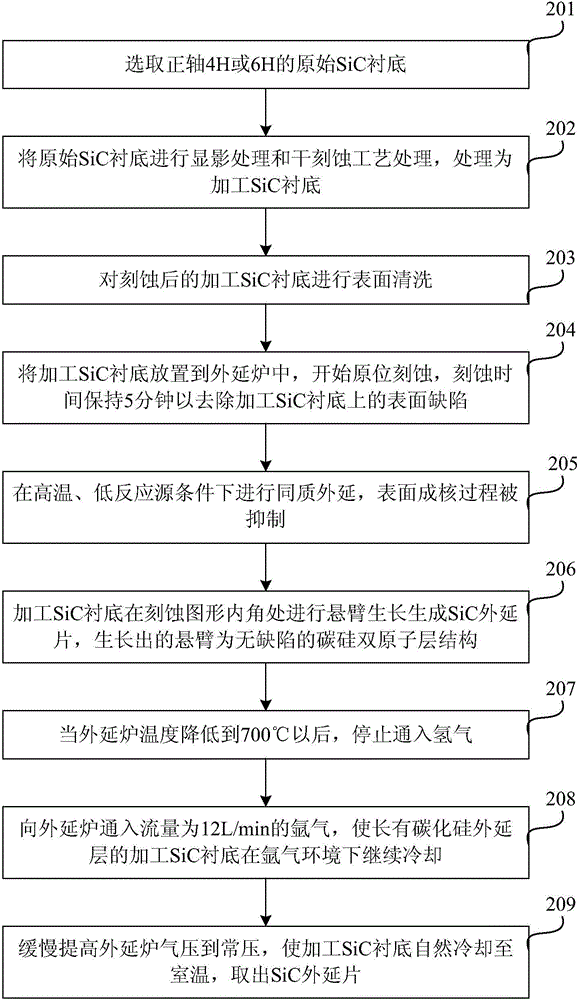

[0023] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

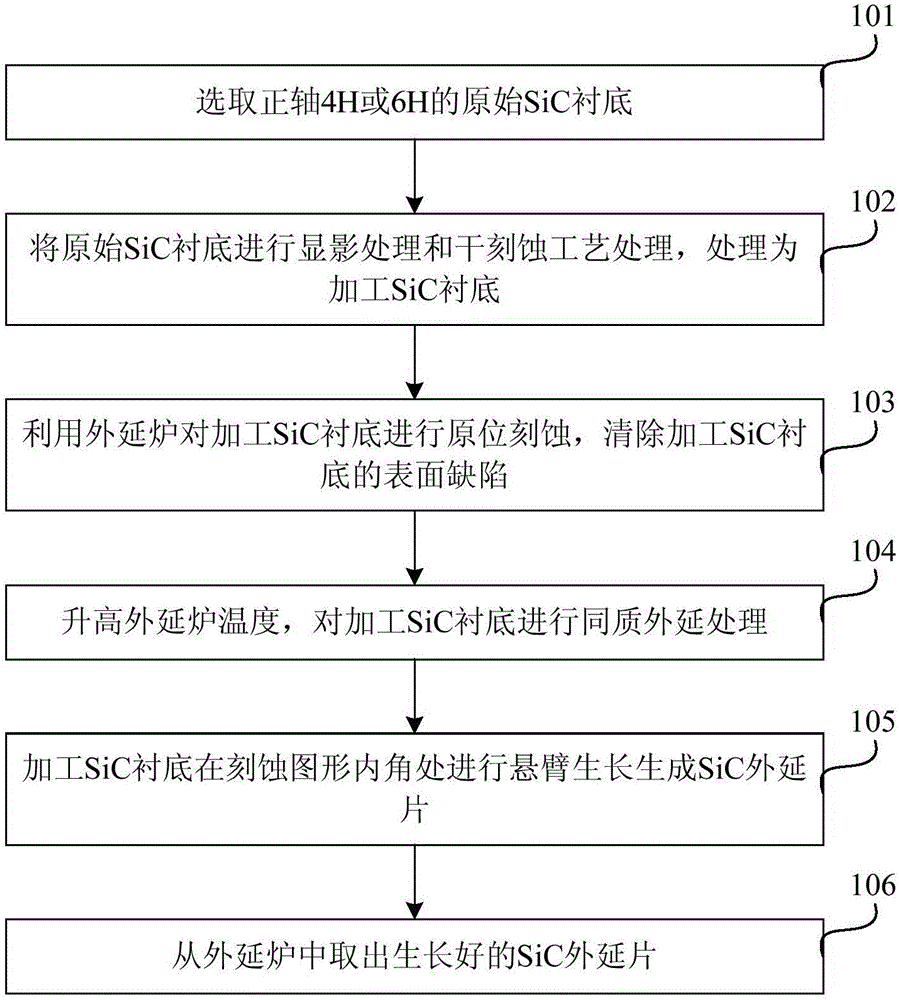

[0024] figure 1 It is a flow chart of Embodiment 1 of the SiC substrate homogeneous Web Growth epitaxy method of the present invention. As shown in the figure, this embodiment specifically includes:

[0025] Step 101, selecting an original SiC substrate with positive axis 4H or 6H;

[0026] In step 102, the original SiC substrate is subjected to development treatment and dry etching process to process the SiC substrate; the SiC substrate becomes a mesa, and the etching area is the area of the device to be manufactured, and the etching depth is 5um to 20um. The table has six spindles;

[0027] Step 103, using an epitaxy furnace to perform in-situ etching on the processed SiC substrate to remove surface defects on the processed SiC substrate;

[0028] Step 104, increasing the temperature of the epitaxial furnace, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com