Coal mining equipment predictive maintenance method based on two-dimensional projection

A technology of equipment and coal mines, applied in the field of predictive factors, can solve problems such as fluctuations or deviations of typical frequency components, failure to realize early warning of fault latency, and poor working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

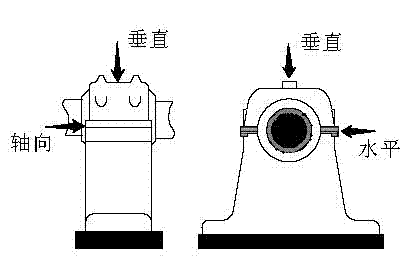

[0100] (1) As a key component of large-scale rotating machinery, bearings are divided into four types of faults: rolling element faults, inner ring faults, outer ring faults, and cage faults. In addition, the four types of faults are based on different damage degrees. It is further divided into different subcategories, which can be divided according to specific circumstances. Install acceleration vibration sensors (such as figure 1 shown), continuously monitor the vibration data of the bearings during the operation of the equipment, and send the vibration data to the back-end receiving and processing system, and store them in relevant data files for back-end analysis.

[0101] (2) For the vibration data extracted from the acceleration vibration sensor {a i ,i=1,2,...,n} to process, the specific steps are:

[0102] ① For vibration data {a i,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com