Safe stress conversion construction method for improvement on main structure of subway station

A technology for main structures and subway stations, which is applied in infrastructure projects, underwater structures, artificial islands, etc. It can solve the problems of construction progress and operability effects, complex transformation of force systems, and reduce the probability of potential safety hazards. , The construction process is safe and reliable, and the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

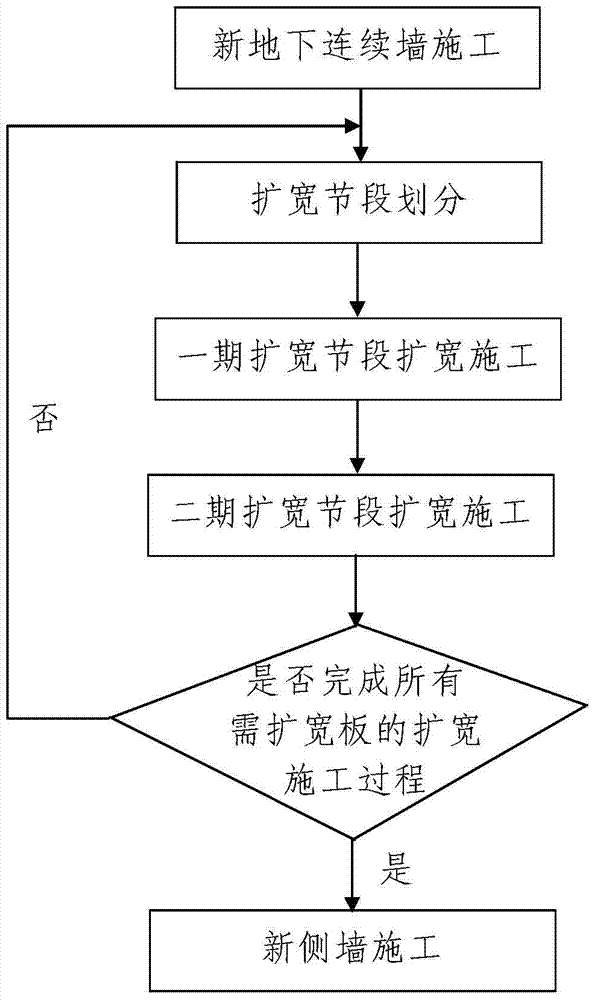

[0050] Such as figure 1 The reconstruction of the main structure of the subway station uses a safe stress conversion construction method. The main structure of the subway station includes the base plate 1, the left wall-4-1 and the right wall-4-1 arranged on the left and right sides of the base plate 1. 2. The top plate 2 located directly above the bottom plate 1 and the middle plate 3 arranged between the top plate 2 and the bottom plate 1, the number of the middle plates 3 is one or more, and a plurality of the middle plates 3 are arranged from top to bottom Between the top plate 2 and the bottom plate 1, the left and right sides of the bottom plate 1, the top plate 2 and the middle plate 3 are connected with the left wall-4-1 and the right wall-4-2 as a whole, see figure 2 between the bottom plate 1 and the middle plate 3 above it, between the top plate 2 and the middle plate 3 below it, and between the upper and lower adjacent two middle plates 3 are supported by a column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com