Drilling pile drilling construction method of bead-type karst area

A construction method and technology of bored piles, applied in the direction of filling, drill bit, sheet pile wall, etc., can solve the problem of providing a relatively complete and systematic theoretical basis, and the guiding documents for bridge pile foundation design are not perfect and lack of system , comprehensiveness and operability, to achieve good treatment effects, easy construction quality assurance, and reasonable components and ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

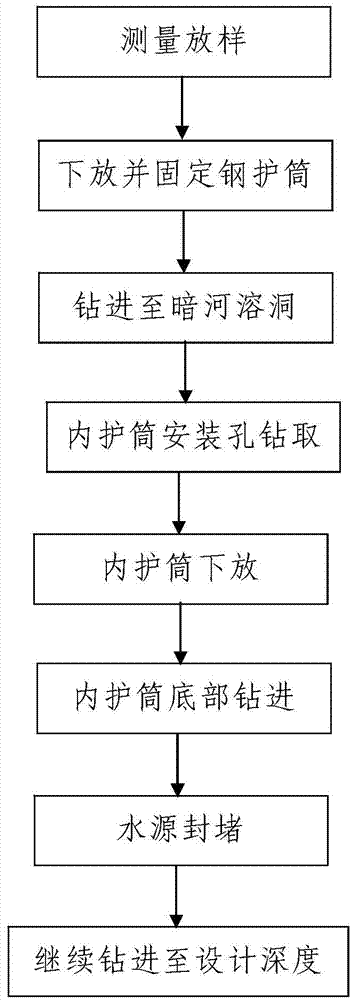

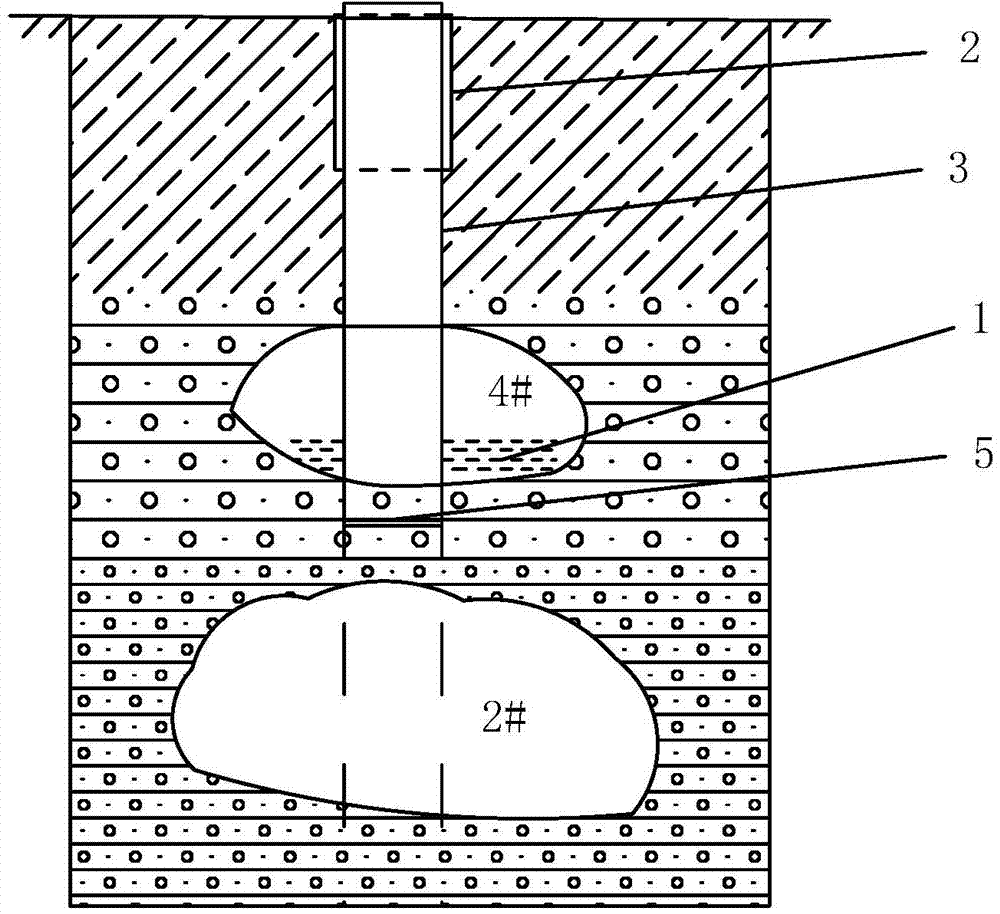

[0049] Such as figure 1 Shown is a bead-type karst area bored pile drilling construction method. The constructed bored piles pass through an underground river karst cave from top to bottom. The underground river karst cave is a karst cave with an underground river 1 at the bottom. See details figure 2 , The method includes the following steps:

[0050] Step 1. Measure and stake out: measure and stake out the pile positions of the currently constructed bored piles.

[0051] In actual construction, the measurement and laying out must be accurate, and the deviation of the pile position must meet the requirements. Lay out the line as required. Once the pile is formed, if the pile position deviation is large, the force on some piles will change. Use a total station to pay off the line, repeat inspections during the pay off process, and compound multi-point control. Then take correction of the deviation, so as to avoid large deviations, causing delays in the construction period and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com