Additive for carbon composite briquette and preparation and using methods thereof

A technology of additives and carbon pellets, which is applied in the field of additives and hot-pressed carbon-containing pellets, can solve the problems of inability to be directly applied, and achieve the effects of reducing cyclic enrichment, small usage amount and simple usage method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

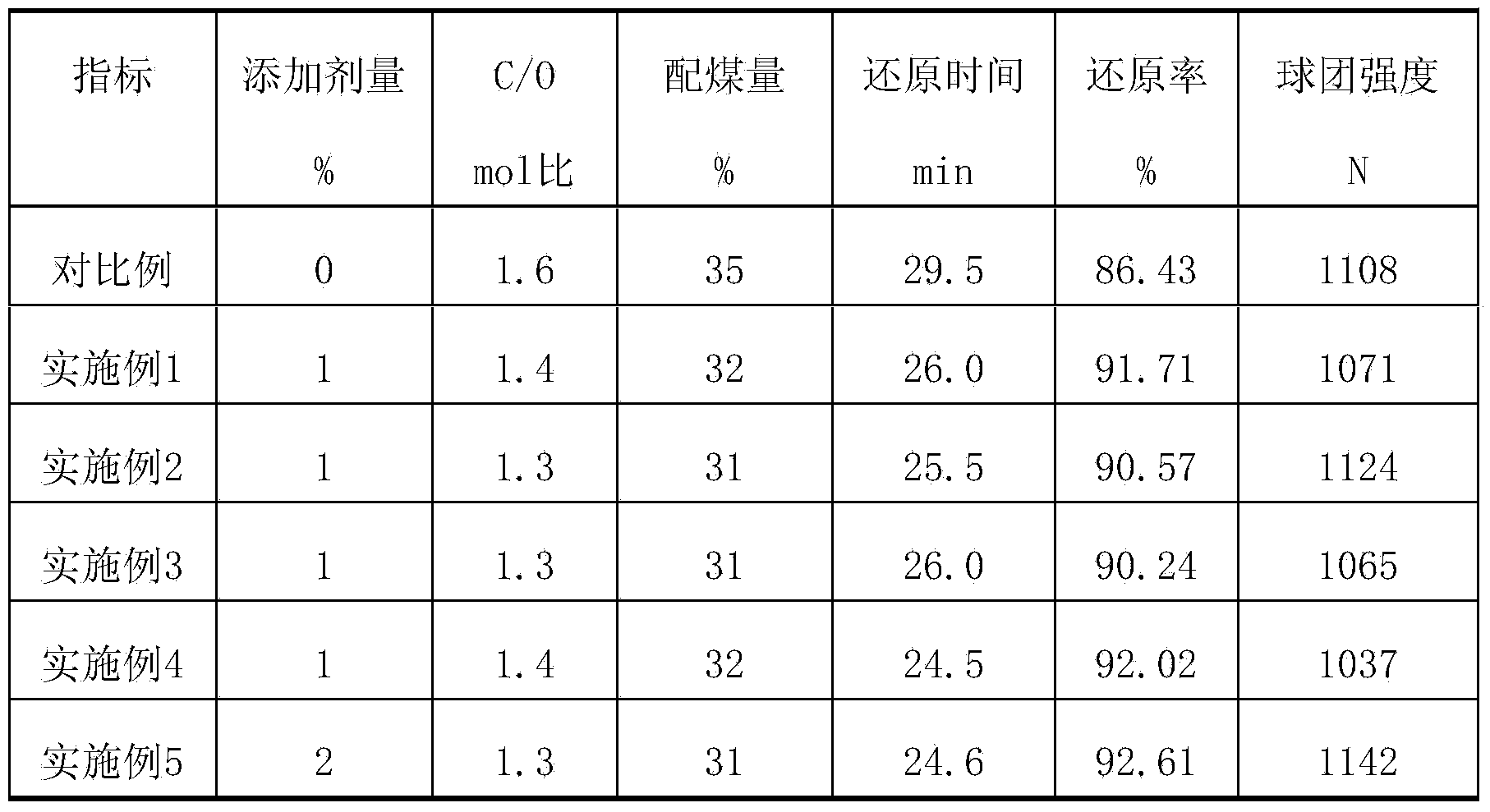

Examples

Embodiment 1

[0026] The raw material components and content are: quicklime 55%, barium oxide 18%, manganese dioxide 18%, and ferrocene 9%. The above-mentioned raw materials are added to the mixing machine and stirred for 10 minutes to make the mixing uniform to obtain the powdery additive.

Embodiment 2

[0028] The raw material components and content are: quicklime 50%, barium oxide 22%, manganese dioxide 19%, and ferrocene 9%. The above-mentioned raw materials are added to the mixing machine and stirred for 15 minutes to make the mixture uniform to prepare the powdery additive.

Embodiment 3

[0030] The raw material components and content are: quicklime 40%, barium oxide 20%, manganese dioxide 30%, and ferrocene 10%. The above-mentioned raw materials are added to the blender and stirred for 20 minutes to make the mixture uniform to prepare the powdery additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com