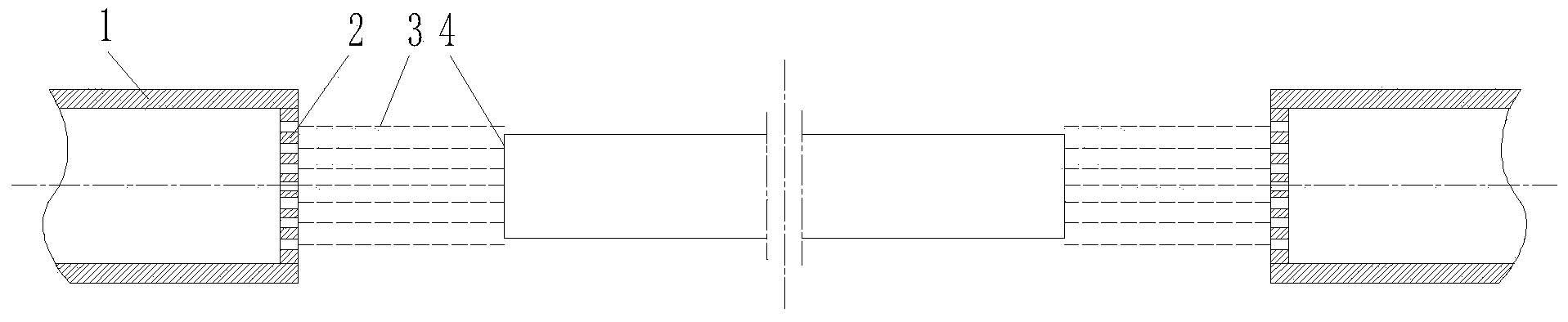

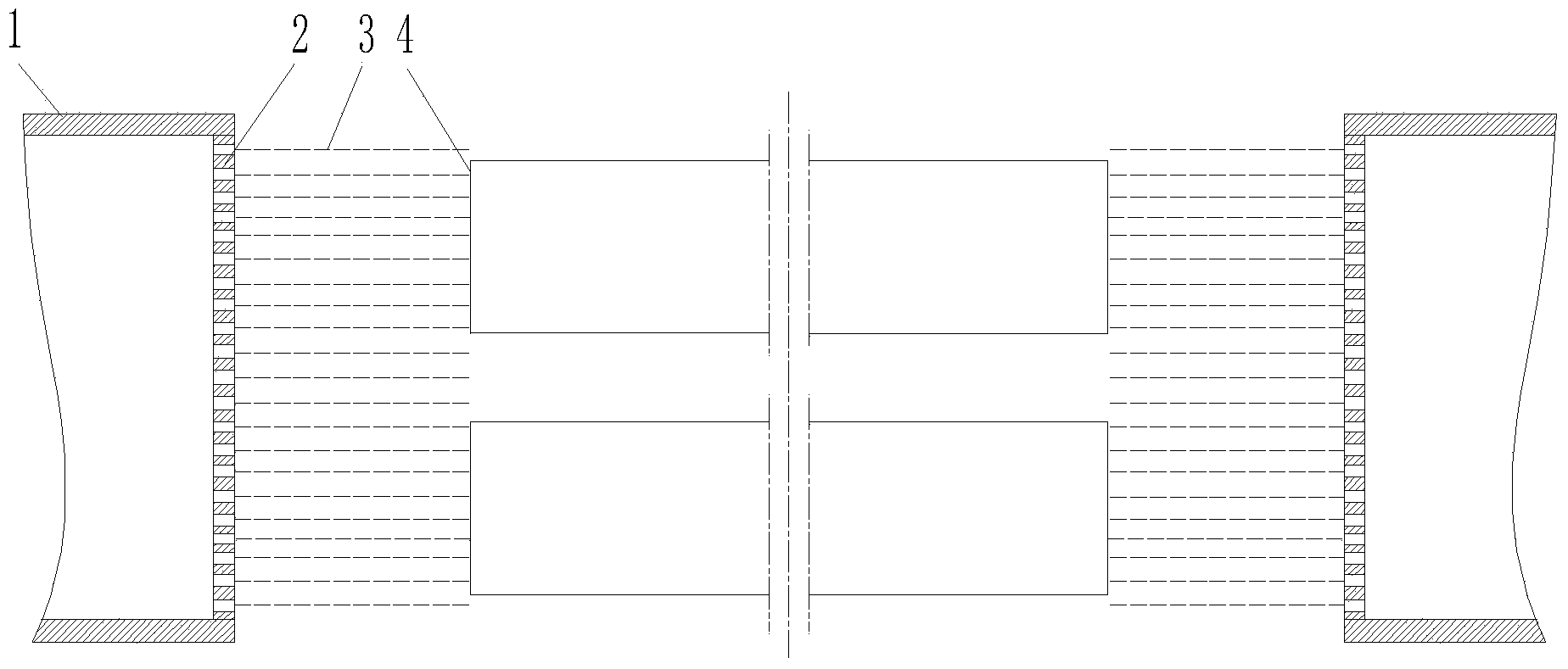

Method for preventing cracking of water quenching end faces of shaft alloy steel parts

An alloy steel, end face technology, applied in the furnace type, heat treatment equipment, furnace and other directions, can solve problems such as excessive stress and cracking, and achieve the effect of avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The processing material is medium carbon alloy steel, the size of the shaft is Ф200*4500 (length) (mm), and the mechanical properties at 1 / 2 of the radius after quenching are required to be higher than the requirements.

[0039] Process: water-air alternately controlled quenching and cooling, the medium is water and air.

[0040]In order to avoid cracking in the outer circle area of the end face during the quenching and cooling process, one of the methods for preventing cracking of the end face of shaft alloy steel parts in water quenching according to the present invention is adopted, that is, to increase the cooling rate of the end face except for the outer circle area of the end face , reduce the temperature difference between the outer surface of the outer circle of the end face and the outer circle of the end face, and reduce the tensile stress at the junction.

[0041] The specific method is to increase the cooling intensity of the end face except for the oute...

Embodiment 2

[0045] The processing material is medium carbon alloy steel, the size of the shaft is Ф200*4500 (length) (mm), and the mechanical properties at 1 / 2 of the radius after quenching are required to be higher than the requirements.

[0046] Process: one-time immersion quenching and cooling. The quenching medium is: polymer water-soluble quenching medium

[0047] In order to avoid cracking in the outer circle area of the end face during the quenching and cooling process, one of the methods for preventing cracking of the end face of shaft alloy steel parts in water quenching according to the present invention is adopted, that is, to reduce the cooling rate at the outer circle area of the end face, and reduce its difference with The temperature difference between the outer surface of the outer circle of the end face reduces the tensile stress at the junction of the outer circle of the end face and the outer surface of the outer circle of the end face.

[0048] The specific method...

Embodiment 3

[0050] The processing material is medium carbon alloy steel, the size of the shaft is Ф200*4500 (length) (mm), and the mechanical properties at 1 / 2 of the radius after quenching are required to be higher than the requirements.

[0051] Process: water-air alternately controlled quenching and cooling, the medium is water and air.

[0052] In order to avoid cracking in the outer circle area of the end face during the quenching and cooling process, one of the methods for preventing cracking of the end face of shaft alloy steel parts in water quenching according to the present invention is adopted, that is, by setting the quenching and cooling process, increasing the self-tempering time and reducing the The supersaturation of carbon in the martensite in the outer circle region of the end face that has undergone martensitic transformation improves the ability of the outer circle region of the end face to resist cracking.

[0053] The specific method is to appropriately prolong the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com