Cooling-liquid medium type hydraulic retarding device for vehicle

A technology of hydraulic retarder and hydraulic retarder, applied in hydraulic brakes, hydraulic resistance brakes, vehicle parts, etc., to achieve the effect of convenient assembly, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

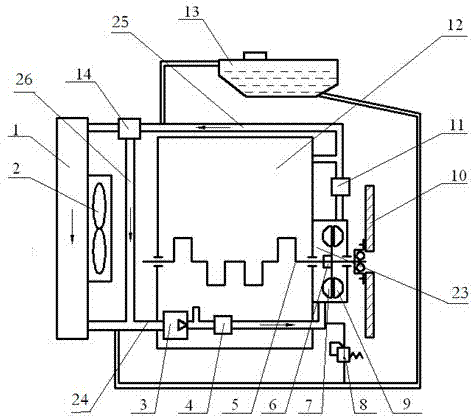

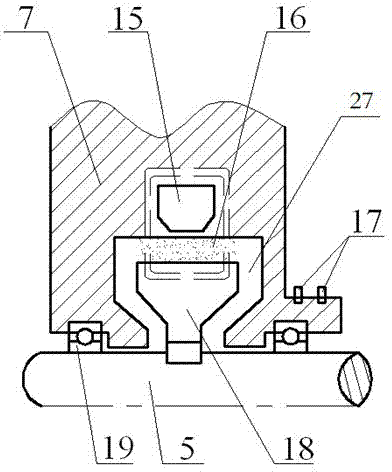

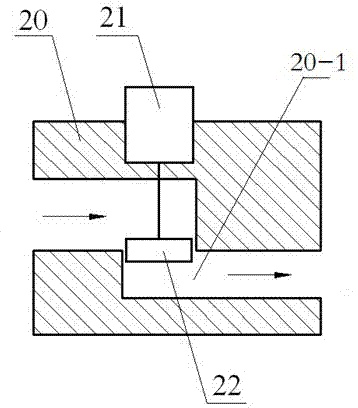

[0027] like Figure 1~3 As shown, a vehicle coolant medium type hydraulic retarder includes a hydraulic retarder and a control unit that can control the operation of the hydraulic retarder. The hydraulic retarder is installed on the vehicle engine crankshaft 5 and flywheel 10 between, and the hydraulic retarder has a retarder working chamber 23, which also includes an inlet pipeline 24, an outlet pipeline 25, a pump 3, a return pipeline 26, and an inlet throttle valve 4 for controlling the coolant flow rate in the inlet pipeline 24 and The outlet throttle valve 11 that controls the flow rate of coolant in the outlet pipeline 25, the liquid outlet end of the return pipeline 26, the inlet pipeline 24, the slow speed working chamber 23, the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com