Biomass polymer hybrid laminated composite material and preparation method

A composite material and polymer material technology, which is applied in the field of biomass-polymer hybrid laminated composite material and preparation, can solve the problems of high energy consumption, large forest resource consumption and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

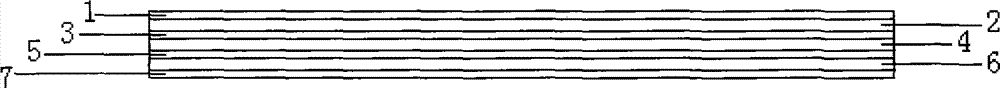

[0048] Specific Embodiment 1: This embodiment consists of an organic polymer material layer, an inorganic polymer material layer, or a polymer material layer, and any inter-layer arbitrary Combining, laminated composite materials with different characteristic characteristics can be obtained. The total number of laminated layers of composite materials is an odd number of layers, and organic polymer material layers, inorganic polymer material layers or polymer material layers are arranged crosswise;

[0049] The organic polymer material layer is composed of a liquid material and a solid material, and the liquid material consists of 2 to 4 parts by weight of polyurethane, 18 to 22 parts of unsaturated resin, 1 to 3 parts of modified starch glue, bone glue or fish scale glue 4-6 parts, 4-6 parts of methyl methacrylate, 4-6 parts of aluminum hydroxide, 4-6 parts of barium chloride, 4-6 parts of diammonium hydrogen phosphate, 1-3 parts of water glass, magnesite modified 0.05-0.15 pa...

specific Embodiment approach 2

[0052] Specific embodiment two: the steps of the preparation method of a kind of biomass polymer hybrid laminated composite material described in this embodiment are as follows:

[0053] Step 1, in the batching system of a kind of biomass multipolymer hybrid laminated composite board material production equipment, set up a magnetic field intensity and be 160 thousand ampere meters, the aqueous solution magnetization machine that water velocity is 0.65 m / min, magnetize with aqueous solution The magnetized water produced by the machine is used to prepare the curing agent for inorganic polymer materials and the dispersant for water-based organic polymer materials, which can increase the structural strength of biomass polymer hybrid laminated composite materials by 30-40%;

[0054] Step 2, preparation of organic polymer materials, inorganic polymer materials or polymer materials:

[0055] Formulation of organic polymeric material layers

[0056]The organic polymer material layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com