A Three-stage Welding Method for Cold Metal Transition of Hollow Stationary Blade of Steam Turbine

A technology of cold metal transition and welding method, which is applied in the field of steam turbines, can solve problems such as difficult control of welding quality, small heat-affected zone, and differences between welding methods and processes, and achieve effective control of welding residual stress and deformation, control of welding residual stress and Deformation, the effect of improving the quality stability of weldments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

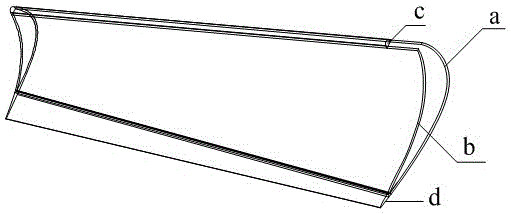

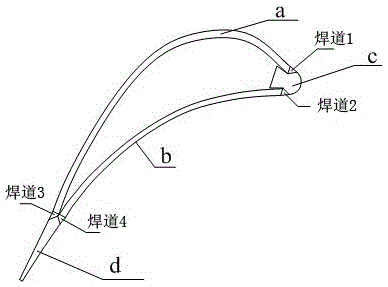

[0028] The structural composition of the steam turbine hollow blade in this embodiment includes a back arc surface a, an inner arc surface b, a leading edge rib c, and a trailing edge curved surface d. The above parts will be connected by four welds to make the hollow blade of the steam turbine. The back arc surface a and inner arc surface b are made of X5CrMoAl12 special blade steel with a thickness of 3.6mm. The thickness of the weld side of the trailing edge surface d is 6.5mm, and the thickness of the transition to the weld side through the curved surface is 1.0mm. The four welds are respectively: the leading edge rib is welded with the back arc surface to form the back arc surface weld 1 of the air inlet side; the front edge rib is welded with the inner arc surface to form the inner arc surface weld seam 2 of the air intake edge; The curved surface is welded to the back arc surface to form a back arc surface weld 3 on the air outlet side; the rear edge curved surface is w...

Embodiment 2

[0051] Weld bead 1 is the arc surface weld of the inlet side (inner arc surface part--leading edge rib), weld bead 2 is the inner arc surface weld seam of the inlet edge (back arc surface part--front edge rib), Bead 3 is the arc surface weld of the gas outlet side (inner arc surface part--the rear edge part of the gas outlet side), and weld bead 4 is the arc surface weld seam of the gas outlet side (back arc surface part--the rear edge part of the gas outlet side).

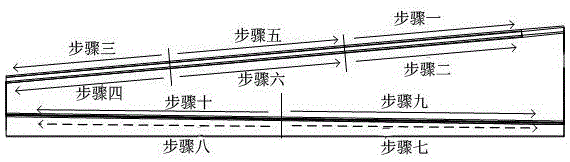

[0052] Welding bead 1 and welding bead 2 are divided into three sections; welding bead 3 and welding bead 4 are divided into two sections respectively; the big head side is called blade root, and the small head side is called blade tip.

[0053] combine image 3 It can be seen that:

[0054] Step 1: Welding bead 2--blade root section, welding direction: the middle part to the blade root side;

[0055] Step 2: Welding bead 1--blade root section, welding direction: the middle part to the blade root side;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com