Scale preventing agent for reverse osmosis membrane and scale preventing method

A reverse osmosis membrane and antiscalant technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0038] First, the scale inhibitor according to the first embodiment of the present invention will be described. The antiscalant of this embodiment suppresses the precipitation of calcium phosphate scale produced in the reverse osmosis membrane treatment, prevents scale from adhering to the RO membrane, etc., and its main component is a unit derived from (meth)acrylic acid and derived from 2- A water-soluble copolymer of (meth)acrylamido-2-methylpropanesulfonic acid constituent units.

[0039]Specifically, the water-soluble copolymer as the main component of the scale inhibitor of this embodiment is a copolymer of (meth)acrylic acid and 2-(meth)acrylamido-2-methylpropanesulfonic acid, or Copolymers with other monomers. Here, "(meth)acrylic acid" means methacrylic acid, acrylic acid, or salts thereof, and these monomers may be used alone or in combination of two or more. In addition, "2-(meth)acrylamido-2-methylpropanesulfonic acid" means 2-methacrylamido-2-methylpropanesulfon...

no. 2 approach

[0057] Next, the scale inhibition method according to the second embodiment of the present invention will be described. The scale inhibition method of the present embodiment is a method of suppressing precipitation of calcium phosphate scale in reverse osmosis membrane treatment using the scale inhibitor of the first embodiment. That is, in the scale inhibition method of this embodiment, a scale inhibitor mainly composed of a water-soluble copolymer having (meth)acrylic acid-derived scale inhibitor is added to the reverse osmosis membrane treatment water system. Units and constituent units derived from 2-(meth)acrylamido-2-methylpropanesulfonic acid, units derived from 2-(meth)acrylamido-2-methylpropanesulfonic acid are 10 to 40 mol %, and the mass average molecular weight is 1×10 4 ~5×10 4 .

[0058] In the scale inhibition method of this embodiment, there is no particular limitation on the method of adding the scale inhibitor, and it can be added at the site where scale a...

Embodiment

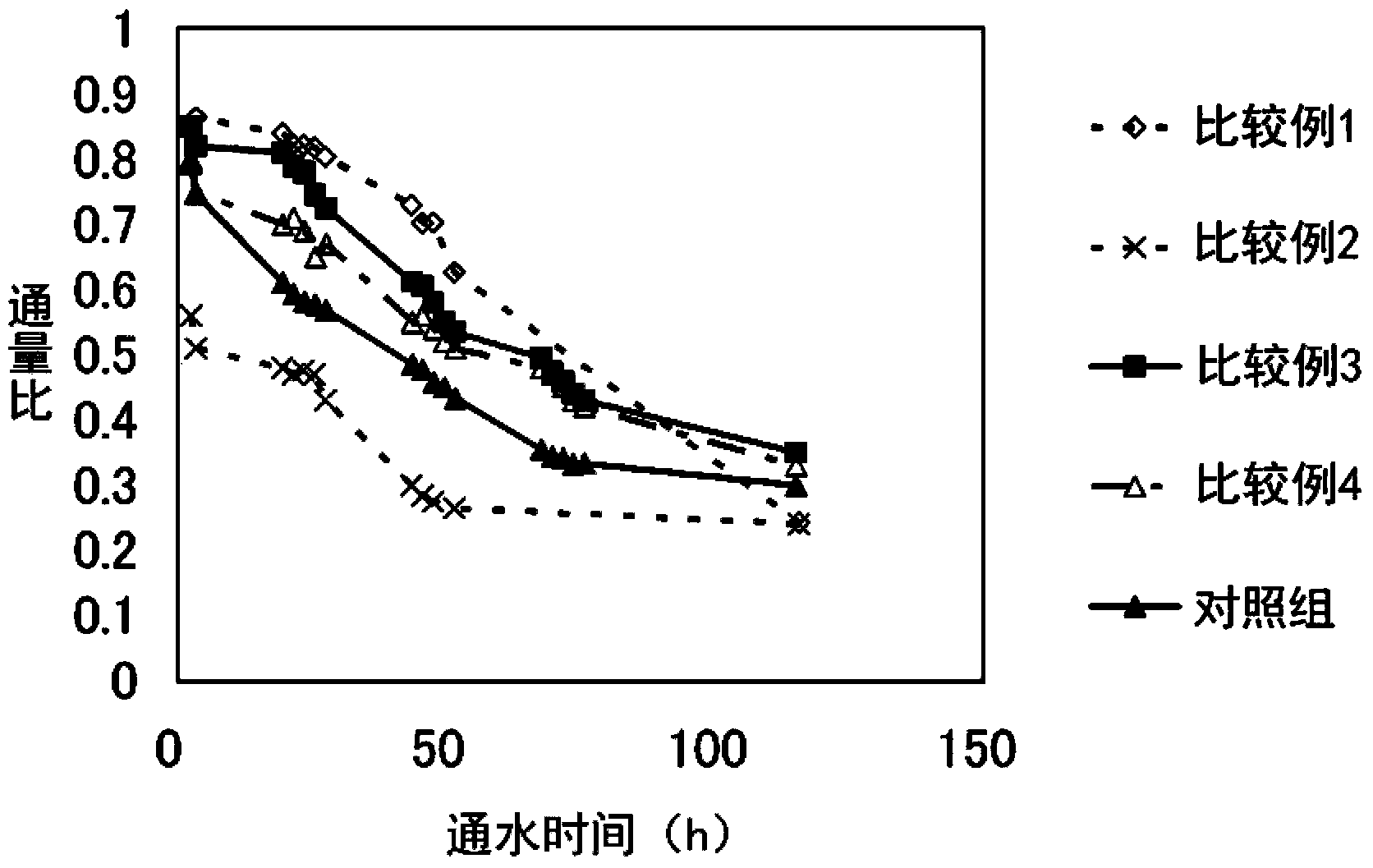

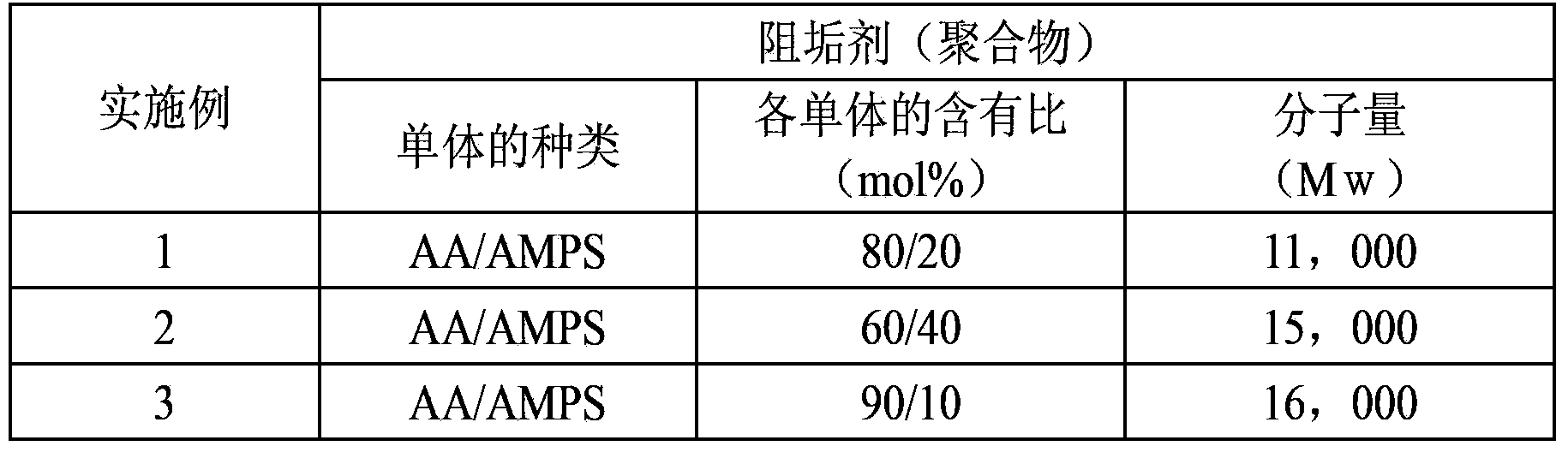

[0067] Hereinafter, the effects of the present invention will be described concretely with reference to Examples and Comparative Examples of the present invention. In this example, the performance of the scale inhibitors of Examples 1 to 3 within the scope of the present invention and the scale inhibitors of Comparative Examples 1 to 4 outside the scope of the present invention was evaluated by the method shown below. The specific data of the scale inhibitors of Examples 1-3 are shown in following Table 1, and the specific data of the scale inhibitors of Comparative Examples 1-4 are shown in following Table 2. In addition, in the respective monomers shown in Table 1 and Table 2 below, AA is acrylic acid, and AMPS is 2-acrylamido-2-methylpropanesulfonic acid.

[0068] [Table 1]

[0069]

[0070] [Table 2]

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com