Traveling-wave tube clamping rod and manufacturing method thereof

A technology for clamping rods and traveling wave tubes, which is applied in the manufacture of discharge tubes/lamps, discharge tubes, and cold cathodes. Effects of flexibility, improvement of dispersion characteristics, and improvement of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] According to one aspect of the present invention, a method for preparing a traveling wave tube ceramic clamping rod is disclosed, comprising the following steps:

[0031] A metal inner core and a ceramic material are selected, and the linear expansion coefficient of the metal inner core is the same or similar to that of the ceramic material;

[0032] First, a layer of metal or alloy layer is plated on the outer surface of the metal inner core, such as one of nickel, copper, silver-copper alloy, gold-copper alloy, germanium-copper alloy, etc., and then on the outer surface of the metal or alloy layer A layer of active metal such as titanium, zirconium, tantalum and niobium is coated on the surface.

[0033] Fixing the metal inner core whose outer surface is coated with a metal layer in the mold for pressing the ceramic clamping rod;

[0034] Fill the mold for pressing the ceramic clamping rod with ceramic material, and start the pressing of the ceramic clamping rod, the...

Embodiment 1

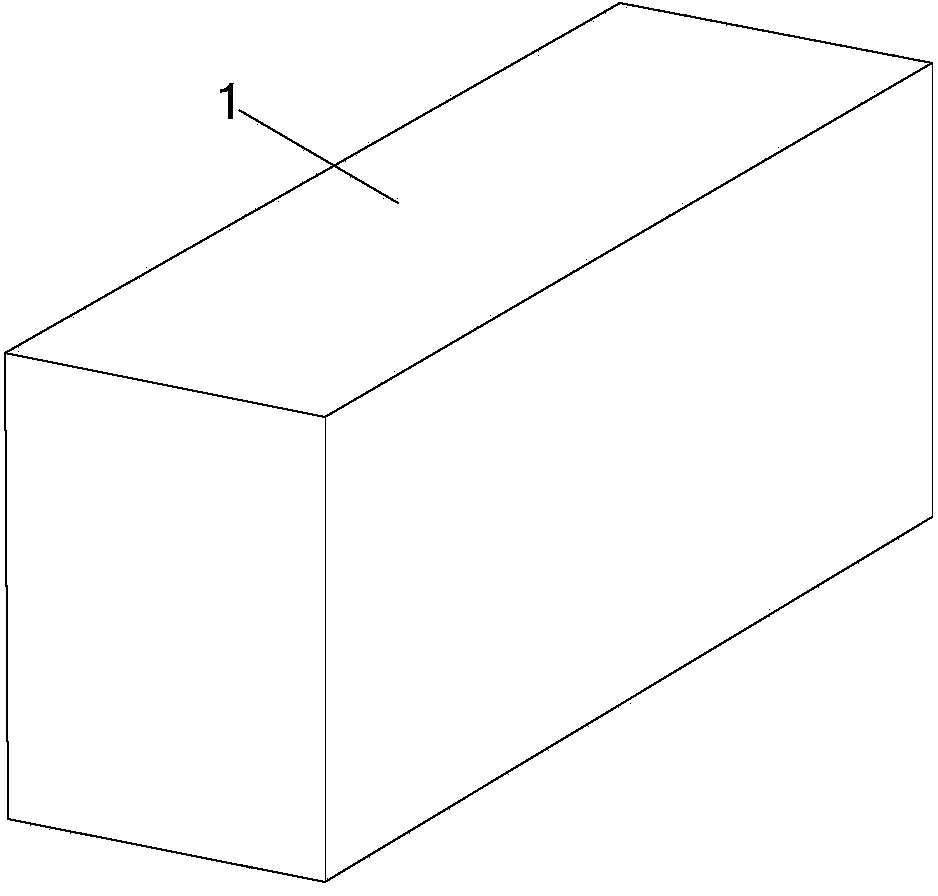

[0038] In this embodiment, the cross-section of the ceramic clamping rod and the metal inner core is a rectangular structure, and the metal inner core is located in the center of the ceramic clamping rod as an example, wherein the material of the ceramic clamping rod is beryllium oxide, and the material of the metal inner core is It is the iron-nickel-cobalt magnetic seal alloy 4J34. The long side x short side x length of the rectangular slot is 4 x 5 x 130mm; the long side x short side x length of the rectangular ceramic clamping rod is 4 x 5 x 130mm; the long side x short side of the rectangular metal core cross section x The length is 2×2.5×130mm. The surface of the metal inner core is coated with a layer of 10μm thick nickel layer and titanium layer, and then the metal strip is fixed in the center of the groove, and the groove is filled with beryllium oxide ceramic powder, which is pressed by a normal beryllium oxide after being compacted by a press. The ceramic sintering...

Embodiment 2

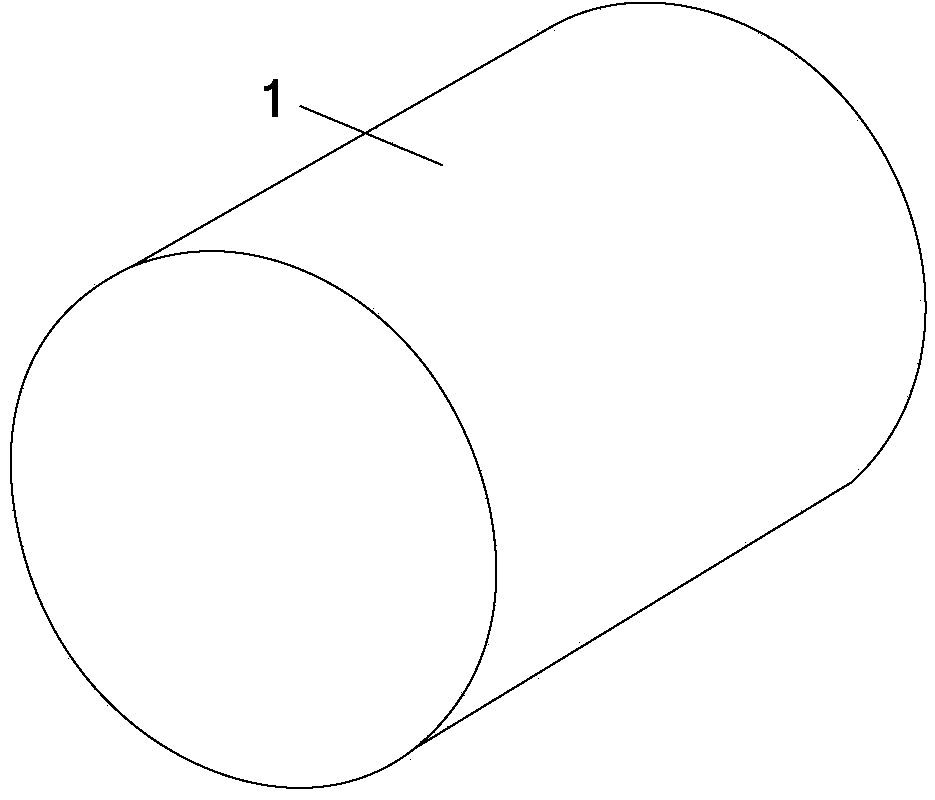

[0041]In this embodiment, both the ceramic clamping rod and the metal inner core have a circular cross-section, and the metal inner core is located in the center of the ceramic clamping rod as an example, wherein the material of the ceramic clamping rod is alumina, and the metal inner core The material is iron-nickel-cobalt magnetic seal alloy 4J33. The radius×length of the circular groove is 4×100mm; the radius×length of the circular ceramic clamping rod is 4×100mm; the radius×length of the cross-section of the circular metal core is 2×100mm. Plating a 10μm-thick copper layer and titanium layer on the surface of the metal inner core, then fix the metal strip in the center of the groove, and fill the groove with alumina ceramic powder, press the normal alumina after compaction by a press The ceramic sintering standard is used for sintering, and after sintering, a ceramic clamping rod with a metal inner core for a traveling wave tube designed by the present invention is formed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com