A transformer anti-burning protection device and using method

A technology of protection device and transformer, applied in transformer/inductor cooling, transformer/inductor components, temperature control by electric method, etc., can solve the problems of slow cooling speed, waste of human resources, easy damage of oil pump, etc. The effect of increasing the contact area, fast heat exchange speed, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

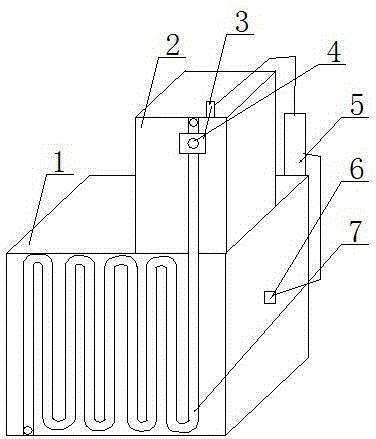

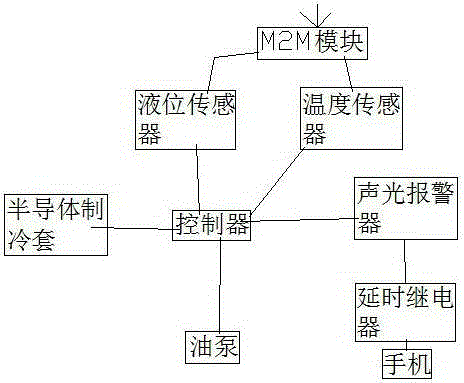

[0023] like figure 1As shown, a transformer anti-burning protection device includes an oil tank 1, an auxiliary oil tank 2 is arranged on the oil tank 1, and an external oil cooling mechanism 7 communicating with it is arranged on one side of the oil tank 1, and the external oil cooling mechanism 7 An oil pump 4 is arranged on the pipeline that the mechanism 7 communicates with the oil tank, and the oil pump 4 is connected with an automatic monitoring and control mechanism. The automatic monitoring and control mechanism includes a sound and light alarm connected to the controller 5, a liquid level sensor 3 and a temperature sensor 6. The sound and light alarm is connected with a delay relay, and the delay relay is provided with a key A mobile phone that is connected to the function. The external oil cooling mechanism is a helically wound metal conduit, and a semiconductor refrigeration kit is arranged on the metal conduit, and the power supply end of the semiconductor refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com