Copper based super-hydrophobic surface with low friction coefficient and preparation method thereof

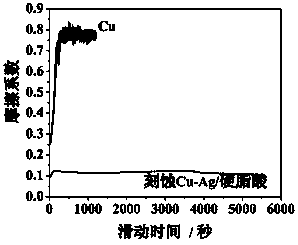

A low friction coefficient, super-hydrophobic surface technology, applied in liquid chemical plating, coating, metal material coating process and other directions, can solve the problems of unstable and easy decomposition of hydrogen peroxide, complex electrochemical process, complex method, etc. It has the advantages of cheap and easy availability of medicines, improved hydrophobicity and tribological properties, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take copper flakes (produced by Sinopharm Group) with a thickness of 0.15-0.25mm and a purity of 99.99% as the copper-based material, and use 1mol L -1 Nitric acid was used for deoxidation film treatment for 10s, then washed with deionized water, dried with nitrogen gas, and set aside.

[0030] (2) Soak the copper sheet treated in step (1) at 40°C in hydrochloric acid with a concentration of 2mol L -1 and ammonium persulfate concentration is 0.1mol L -1 The etching reaction was carried out for 1 h in the mixed solution, and a solid surface with a micron-scale pit structure was obtained.

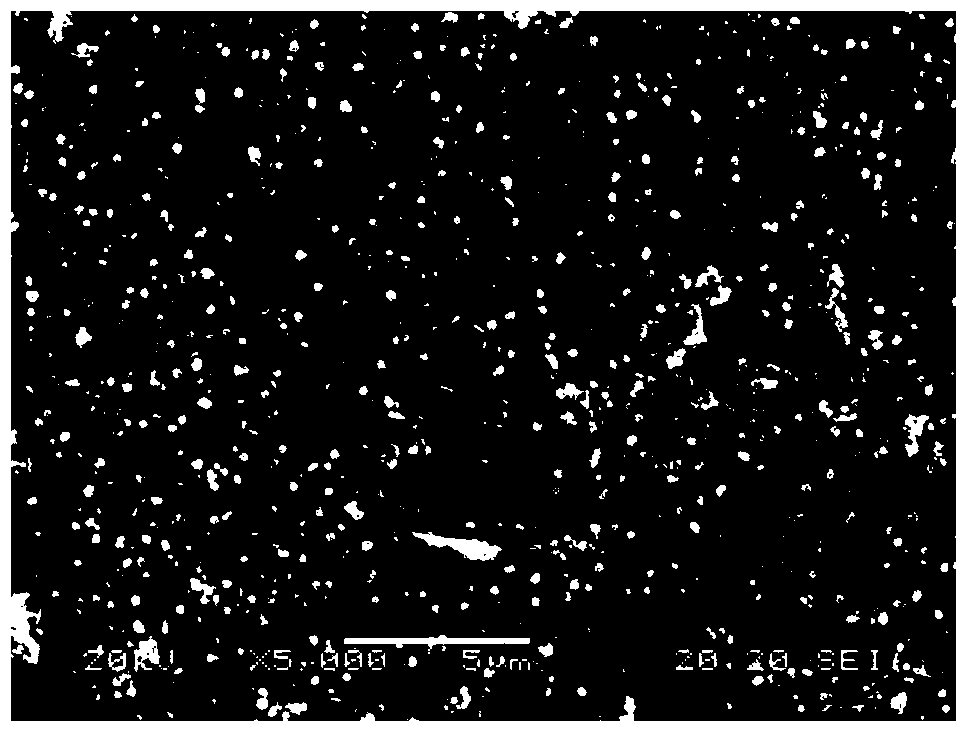

[0031] (3) Soak the copper sheet treated in step (2) in 0.00031mol L at 23°C -1 silver nitrate solution for 5 hours, washed with deionized water, and dried to obtain a copper sheet with a micron-scale pit structure and a rough structure of submicron / nano-scale metallic silver particles.

[0032] (4) Through surface modification, the copper sheet with micron-scale pit structure a...

Embodiment 2

[0035] (1) Take copper with a thickness of 1.5-2mm and a purity of 99% as the substrate, and use 1mol L -1 Nitric acid was used for deoxidation film treatment for 10 seconds, cleaned, and dried with nitrogen gas for later use.

[0036] (2) Soak the copper treated in step (1) in hydrochloric acid with a concentration of 4mol L at a temperature of 10°C -1 , the concentration of potassium persulfate is 0.5mol L -1 The etching reaction was carried out in the mixed solution of 2h, and a solid surface with a micron-scale pit structure was obtained.

[0037] (3) Soak the copper sheet treated in step (2) at 10°C in a concentration of 0.0002mol L -1 in the silver nitrate solution for 4 hours, washed with deionized water, and dried to obtain copper with a micron-scale pit structure and a rough structure of submicron / nano-scale metallic silver particles.

[0038] (4) Using surface modification, the copper with micron-scale pit structure and sub-micron / nano-scale metal silver particle ...

Embodiment 3

[0041] (1) Take a copper sheet (produced by Sinopharm Group) with a thickness of 0.15-0.25mm and a purity of 99.99% as the substrate, and use 1mol L -1 Nitric acid was used for deoxidation film treatment for 10 seconds, cleaned, and dried with nitrogen gas for later use.

[0042] (2) Soak the copper sheet treated in step (1) in hydrochloric acid with a concentration of 2mol L at a temperature of 23°C -1 , the concentration of ammonium persulfate is 0.1mol L -1 4h in the mixed etching solution to obtain a solid surface with a micron-scale pit structure;

[0043] (3) Soak the copper sheet treated in step (2) in 0.00031mol L at 23°C -1 In the silver nitrate solution for 5h, wash with deionized water to obtain a copper sheet with a micron-scale pit structure and a rough structure of submicron / nano-scale metallic silver particles;

[0044] (4) Using surface modification, the copper sheet with micron-scale pit structure and sub-micron / nano-scale metal silver particle rough struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com