Waste concrete superfine regenerated active micro-powder and preparation method thereof

A waste concrete and active micropowder technology, applied in the field of building materials, can solve the problems of high water content, low utilization rate, high water absorption rate, etc., achieve the effect of reducing cement consumption, significant modification effect, and high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The waste concrete raw materials are dried and ball milled for 15 minutes. Glycerol, triisopropanolamine and water are mixed in a certain proportion, and evenly sprayed on the waste concrete powder by spraying. 2.5% of mass. Finely grind the concrete powder mixed with the composite additive for 5 minutes to obtain the desired product.

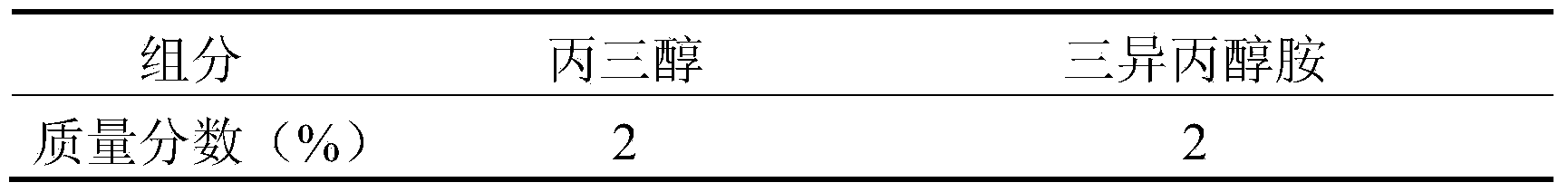

[0016] Table 1 Composite Additive Ratio

[0017]

[0018] When the concentration of polymer compound in the composite additive is 4wt% (glycerol content 2wt%, triisopropanolamine content 2wt%), the specific surface area of waste concrete ultrafine regenerated active micropowder reaches 793m 2 / kg, 45μm fineness below 1.8%; particle size distribution median diameter D50 is 17-20μm, D90 is 60-65μm. When no composite additive is added, the specific surface area of the obtained concrete ultrafine regenerated active micropowder is 609m 2 / kg.

[0019] Concrete ultrafine recycled active micropowder is mixed into cement mortar as a c...

Embodiment 2

[0023] The waste concrete raw materials are dried and ball-milled for 15 minutes, glycerin, triisopropanolamine and water are mixed in a certain proportion, and evenly sprayed on the waste concrete powder in the form of a spray, and the amount of the compound additive is the mass of the waste concrete powder 2.5%. Finely grind the concrete powder mixed with the composite additive for 5 minutes to obtain the desired product.

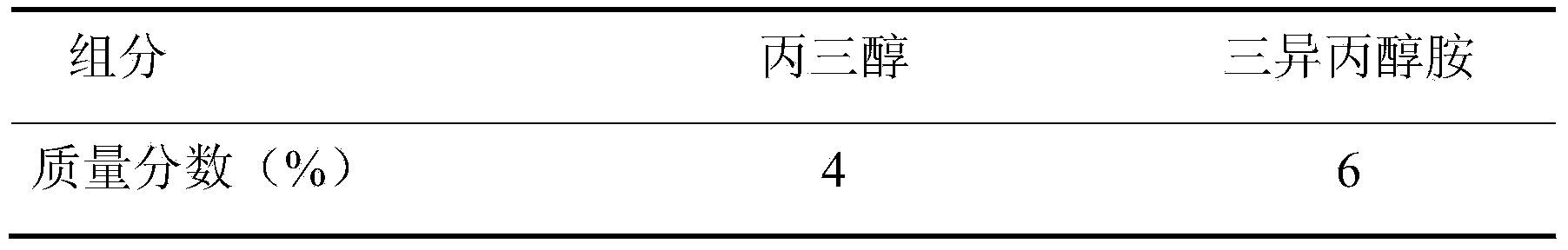

[0024] Table 3 Composite Additive Ratio

[0025]

[0026] When the concentration of polymer compound in the composite additive is 10wt% (glycerol content 4wt%, triisopropanolamine content 6wt%), the specific surface area of waste concrete ultrafine regenerated active micropowder reaches 864m 2 / kg, 45μm fineness below 1.8%; particle size distribution median diameter D50 is 17-20μm, D90 is 60-65μm. When no composite additive is added, the specific surface area of the obtained concrete ultrafine regenerated active micropowder is 609m 2 / kg.

[00...

Embodiment 3

[0031] The waste concrete raw materials are dried and ball-milled for 15 minutes, glycerin, triisopropanolamine and water are mixed in a certain proportion, and evenly sprayed on the waste concrete powder in the form of a spray, and the amount of the compound additive is the mass of the waste concrete powder 2.5%. Finely grind the concrete powder mixed with the composite additive for 5 minutes to obtain the desired product.

[0032] Table 5 Composite Additive Ratio

[0033]

[0034] When the concentration of polymer compound in the composite additive is 10wt% (glycerol content 6wt%, triisopropanolamine content 4wt%), the specific surface area of concrete ultrafine regenerative active micropowder reaches 819m 2 / kg, 45μm fineness below 1.8%; particle size distribution median diameter D50 is 17-20μm, D90 is 60-65μm. When no composite additive is added, the specific surface area of the obtained waste concrete ultrafine regenerated active micropowder is 609m 2 / kg.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com