A kind of preparation method of underground worker's protective clothing fabric

A technology of protective clothing and fabrics, which is applied in the direction of protective clothing, clothing, clothing, etc., can solve the problems of distinguishing between workers and adverse effects of the working environment, small underground working space, and unfavorable search and rescue of trapped personnel, and achieves excellent water and oil repellency. The effect of increased surface roughness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

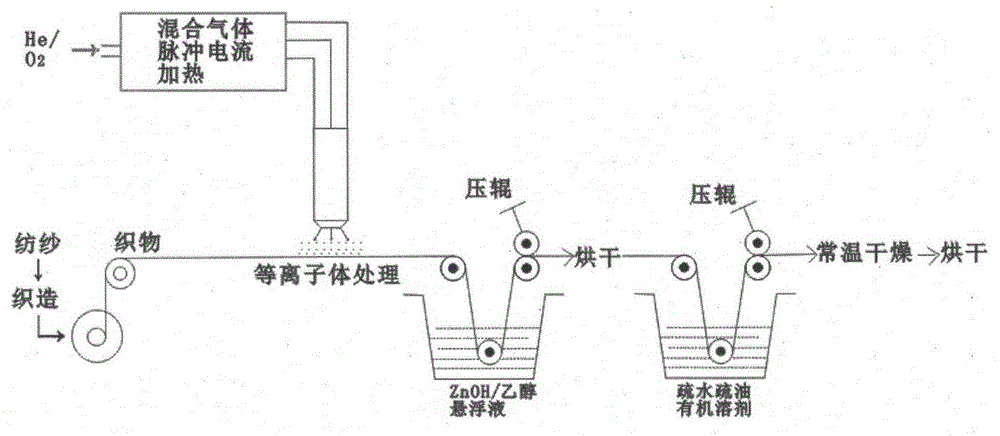

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of underground worker's protective clothing fabric, concrete steps are:

[0031] (1) Cotton fibers, polyester fibers and PEN fibers are used to blend into yarns, the cotton fibers are beige cotton fibers (purchased from Ningbo Golden Bay Printing and Dyeing Co., Ltd.), and the polyester fibers are trefoil-shaped special-shaped cross-section polyester Fiber (purchased from Dongyang Baiyun Awei Chemical Fiber Processing Factory, 7D-64), the PEN fiber described is the antistatic PEN fiber that adopts antistatic masterbatch and PEN chips to carry out blend spinning and makes (purchased from Beijing Kaitai Xin Century Biotechnology Co., Ltd.), the blending ratio of cotton fiber, polyester fiber and PEN fiber is 20:40:40, and the fineness of the blended yarn is 8 pounds;

[0032] (2) The blended yarn is woven into a twill weave; the twill weave is a full-line twill weave with two up and one down, the warp fineness is 8 pounds, the weft fineness is...

Embodiment 2

[0038] A kind of preparation method of underground worker's protective clothing fabric, concrete steps are:

[0039] (1) Cotton fibers, polyester fibers and PEN fibers are used to blend into yarns, the cotton fibers are beige cotton fibers (purchased from Ningbo Golden Bay Printing and Dyeing Co., Ltd.), and the polyester fibers are trefoil-shaped special-shaped cross-section polyester Fiber (purchased from Dongyang Baiyun Awei Chemical Fiber Processing Factory, 7D-64), the PEN fiber described is the antistatic PEN fiber that adopts antistatic masterbatch and PEN chips to carry out blend spinning and makes (purchased from Beijing Kaitai Xin Century Biotechnology Co., Ltd.), the blending ratio of cotton fiber, polyester fiber and PEN fiber is 20:40:40, and the fineness of the blended yarn is 8 pounds;

[0040] (2) The blended yarn is woven into a twill weave; the twill weave is a full-line twill weave with two up and one down, the warp fineness is 8 pounds, the weft fineness is...

Embodiment 3

[0046] A kind of preparation method of underground worker's protective clothing fabric, concrete steps are:

[0047] (1) Cotton fibers, polyester fibers and PEN fibers are used to blend into yarns, the cotton fibers are beige cotton fibers (purchased from Ningbo Golden Bay Printing and Dyeing Co., Ltd.), and the polyester fibers are trefoil-shaped special-shaped cross-section polyester Fiber (purchased from Dongyang Baiyun Awei Chemical Fiber Processing Factory, 7D-64), the PEN fiber described is the antistatic PEN fiber that adopts antistatic masterbatch and PEN chips to carry out blend spinning and makes (purchased from Beijing Kaitai Xin Century Biotechnology Co., Ltd.), the blending ratio of cotton fiber, polyester fiber and PEN fiber is 20:40:40, and the fineness of the blended yarn is 8 pounds;

[0048] (2) The blended yarn is woven into a twill weave; the twill weave is a full-line twill weave with two up and one down, the warp fineness is 8 pounds, the weft fineness is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com