Production method of agricultural greenhouse framework

A production method and technology for agricultural greenhouses, applied in the field of modern agricultural facilities, can solve the problems of cumbersome, easy to scratch the greenhouse film, complex production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Take each component according to Table 5, and set aside;

[0053] 2) First put the plant fiber filler and plastic in a high-speed mixer, mix at a high speed (475-950r / min) and stir for 3 minutes, then add heat stabilizers, plasticizers, lubricants, modifiers, compatibilizers ( If any), coupling agent, foaming agent, foaming aid, nucleating agent and inorganic materials are mixed and stirred. When the temperature of the material reaches 100°C, open the hopper cover on the high-speed mixer to let the plant fiber filler The contained moisture is distributed; continue to stir, and when the temperature of the material drops to 120°C, feed from the high-speed mixer to the cold mixer, and perform low-speed mixing (100r / min) stirring, and when the temperature of the material drops to 40°C, discharge , the resulting mixture is placed in a plastic granulator for granulation (the granulation temperature is 130-160°C) to obtain the base material;

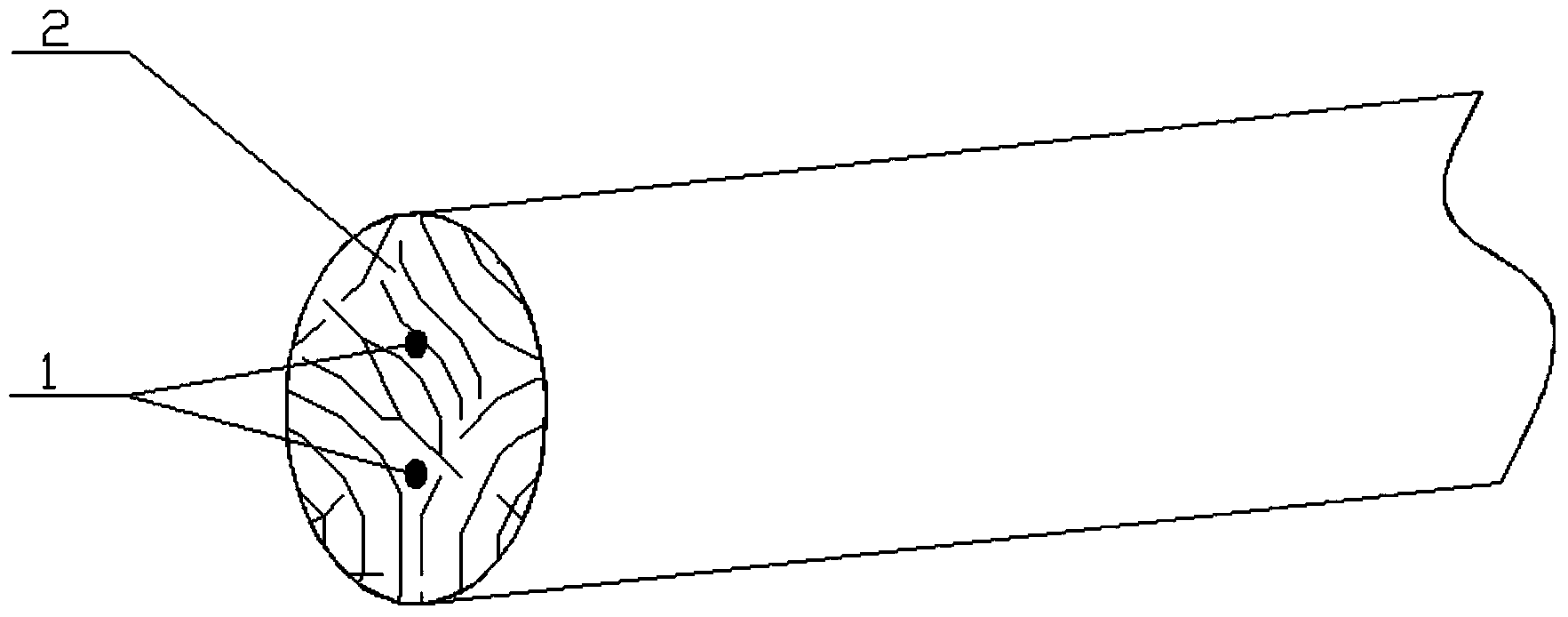

[0054] 3) Use 2 iron wires (t...

Embodiment 2

[0057] 1) Take each component according to Table 5, and set aside;

[0058] 2) with embodiment 1;

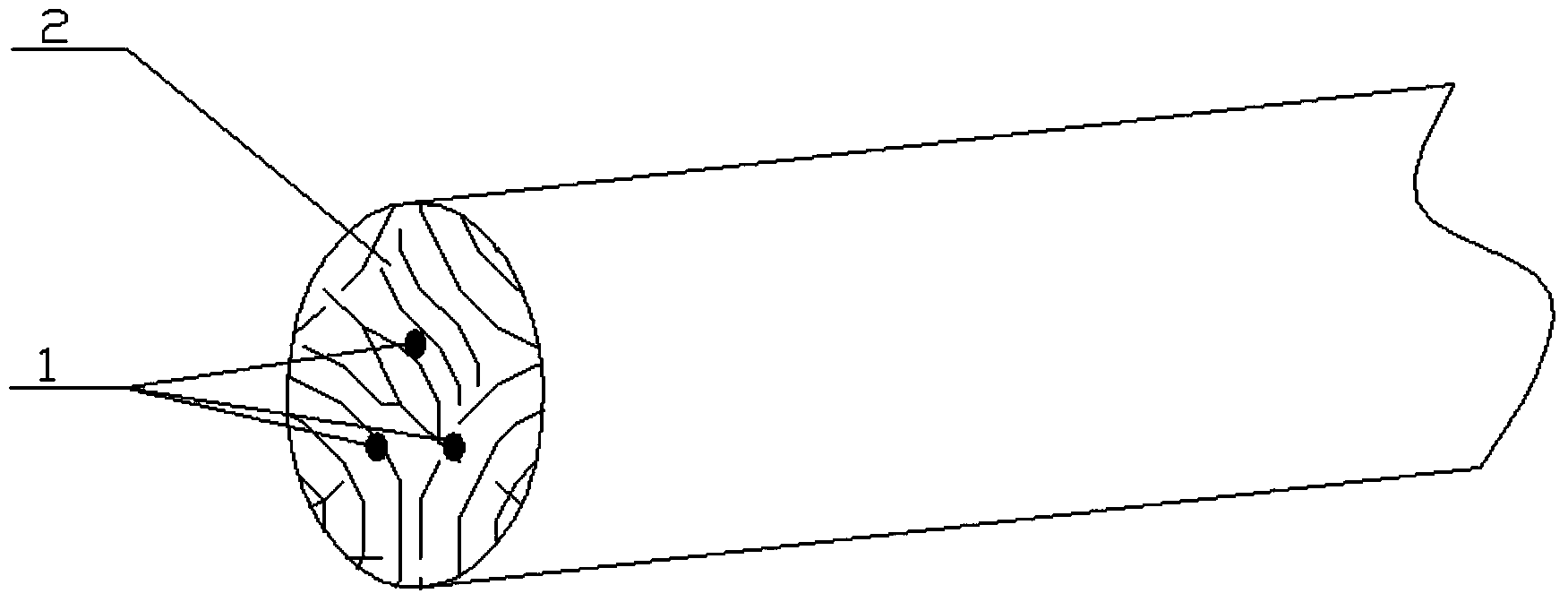

[0059] 3) Same as Example 1, the difference is that the extrusion temperature is set to be 160-200°C, and 3 iron wires (arranged in an equilateral triangle, the equilateral length of the triangle is 15mm) are used as the skeleton lining, and the resulting product is as follows: figure 2 shown.

Embodiment 3

[0061] 1) Take each component according to Table 5, and set aside;

[0062] 2) with embodiment 1;

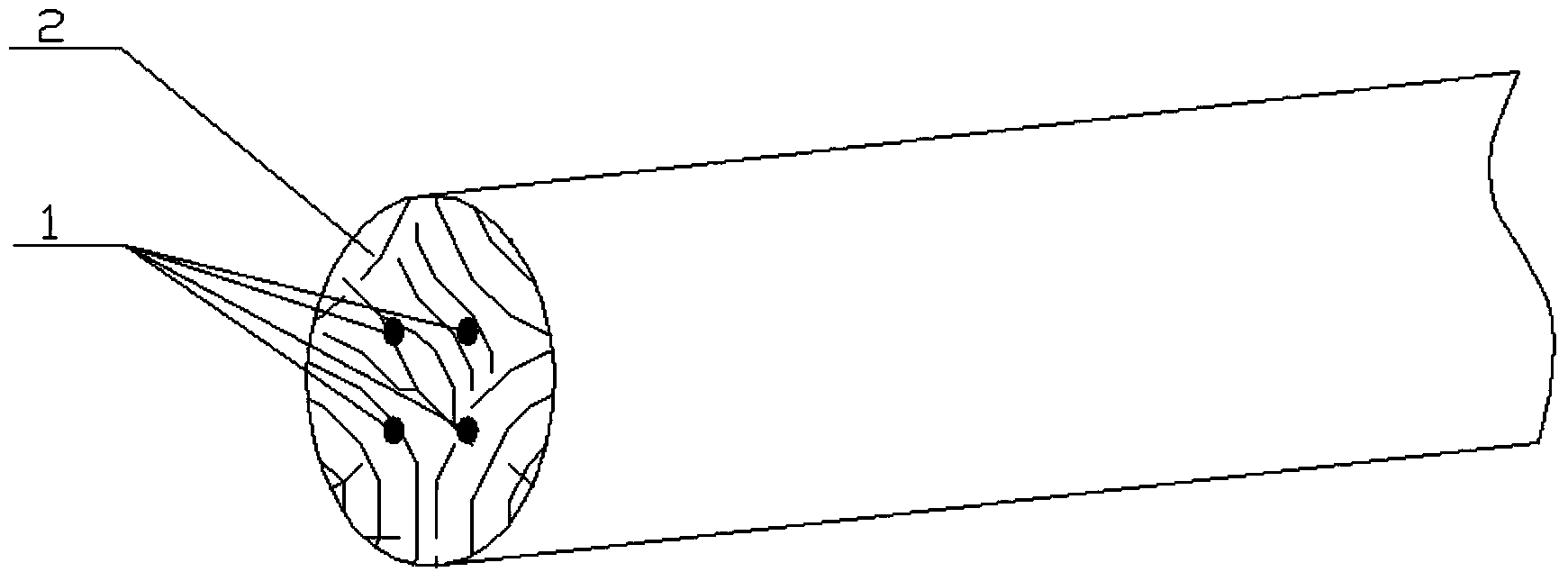

[0063] 3) Same as Example 1, the difference is that the extrusion temperature is set to be 160-200°C, and 4 iron wires (arranged in a square, the side length of the square is 20mm) are used as the skeleton lining, and the resulting product is as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com