Substrate positioning and processing method and substrate positioning and processing device

A processing method and processing device technology, applied in the direction of the work carrier, can solve the problem of not being able to position and grind multiple substrates at one time, and achieve the effects of improving processing efficiency and utilization rate, improving utilization rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

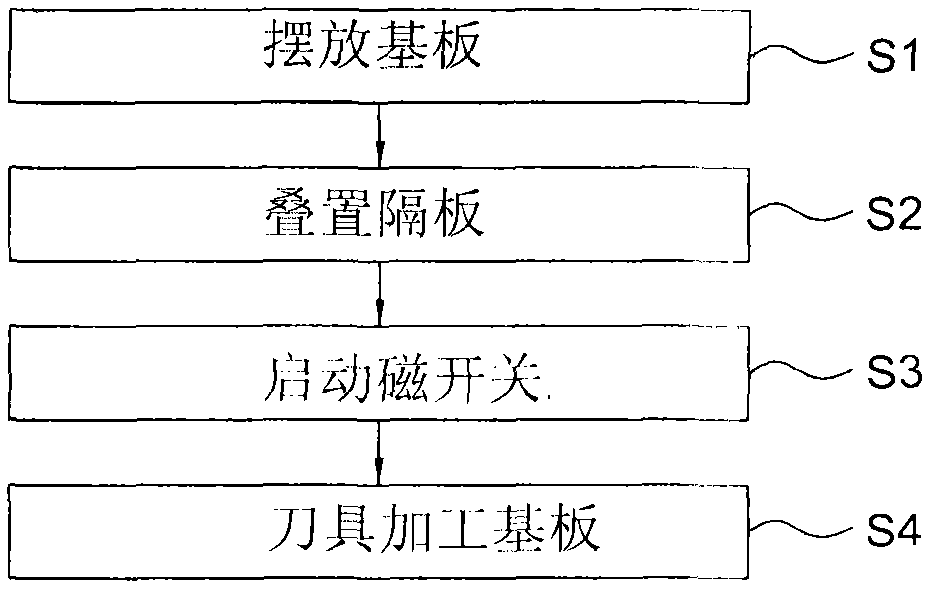

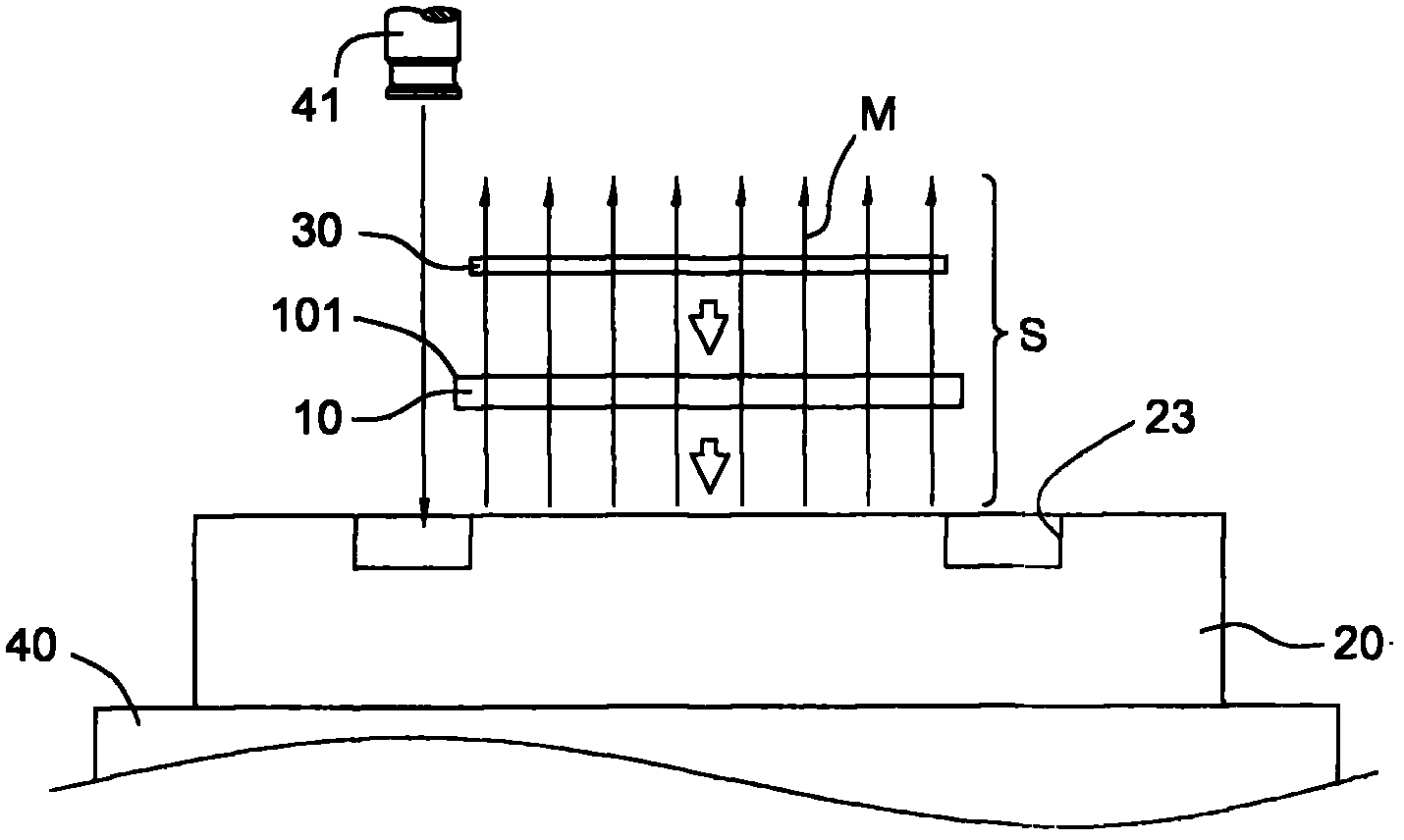

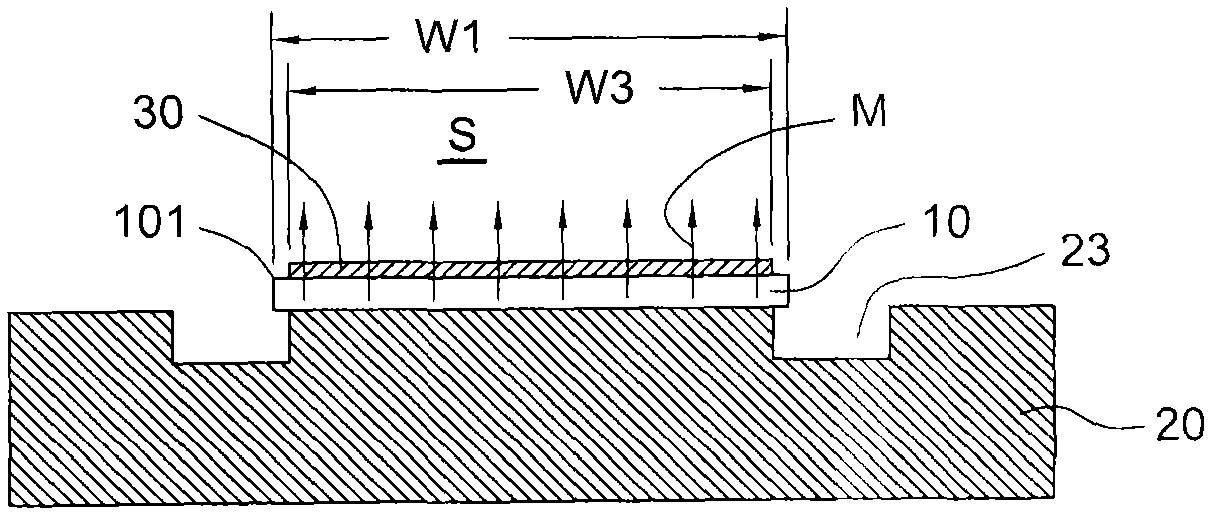

[0039] The purpose of implementing the substrate positioning and processing method and device of the present invention is to firmly position the substrate on the processing tool before processing the substrate, so as to facilitate the processing. The substrate can be, for example, a substrate used for touch control or protection purposes, or a substrate used for solar panels. These substrates are usually made of glass, and therefore can also be referred to as glass substrates. Since the glass substrate itself does not have the characteristics of magnetic conductivity (that is, it is non-magnetic) and can be passed through by magnetic lines of force, it is suitable to be placed in a magnetic field environment without being disturbed by magnetic lines of force. In addition, the processing tool may be, for example, a grinding tool used for grinding the peripheral edges of the glass substrate. However, the actual substrates and processing tools are not limited to the above, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com