Magneto-rheological high-precision positioning device and magneto-rheological removing function transformation method

A positioning device and high-precision technology, which is applied to the parts of grinding machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems affecting the cost and efficiency of magnetorheological processing, difficulty in smoothness control, and high cost. Achieve no residual stress, accurate analysis results, and good positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further explained:

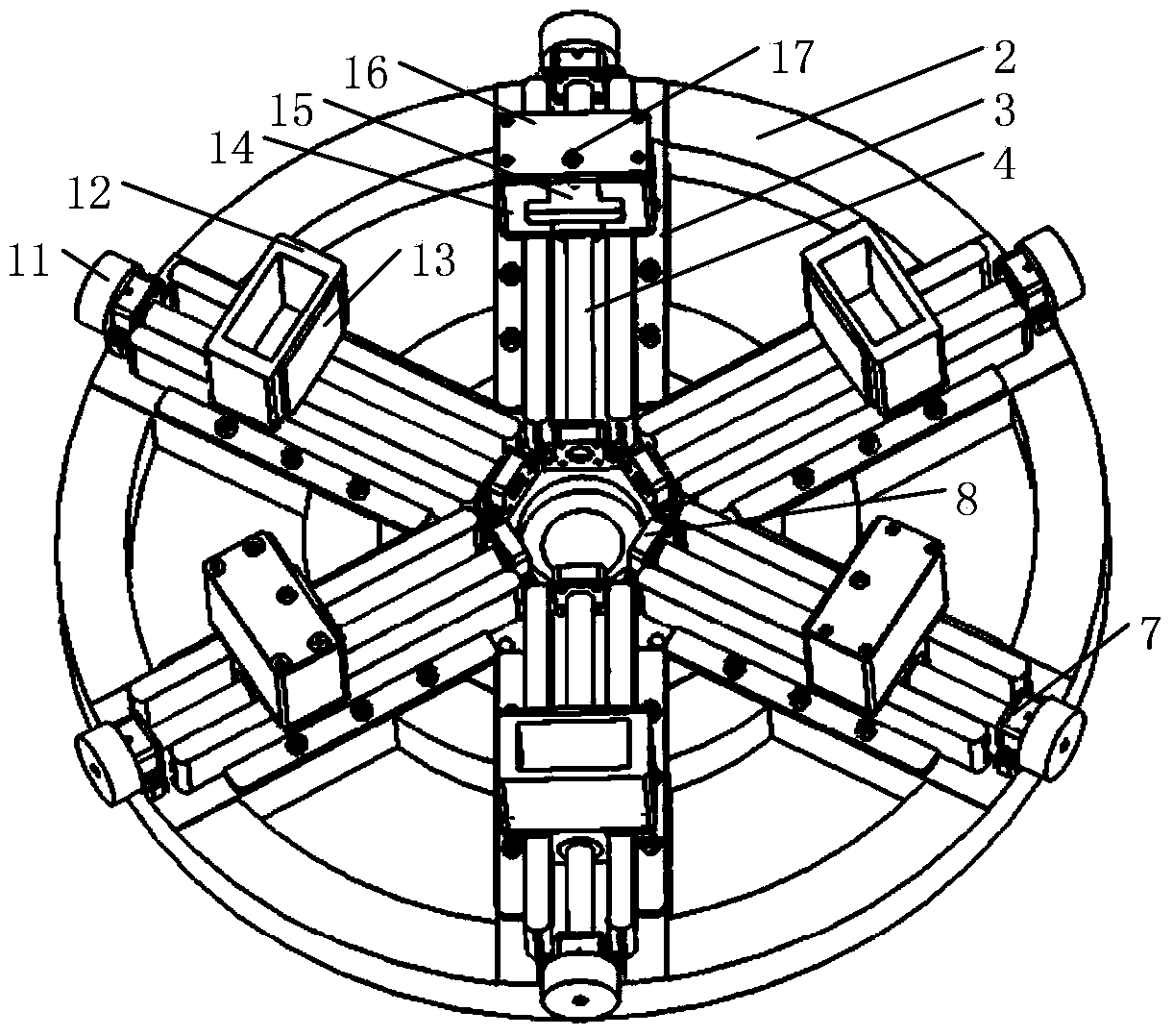

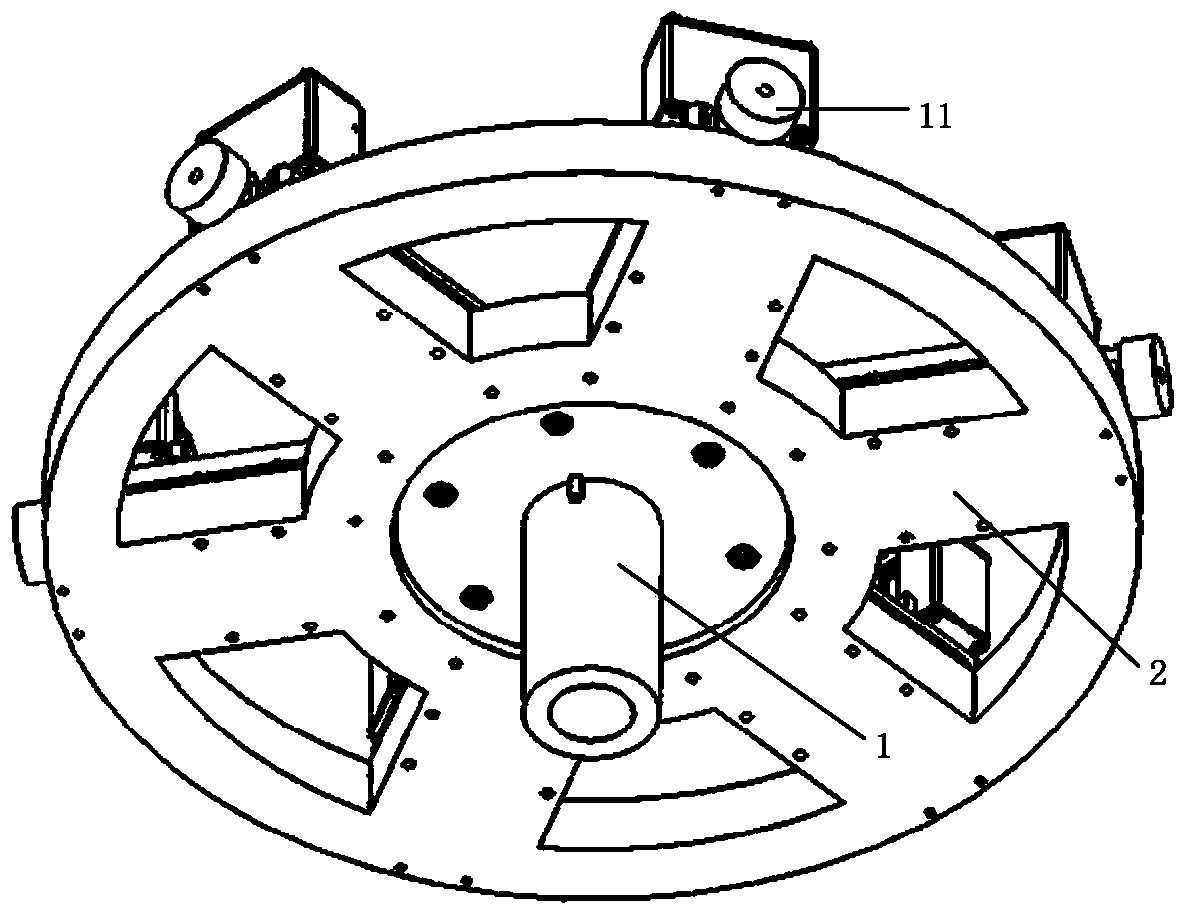

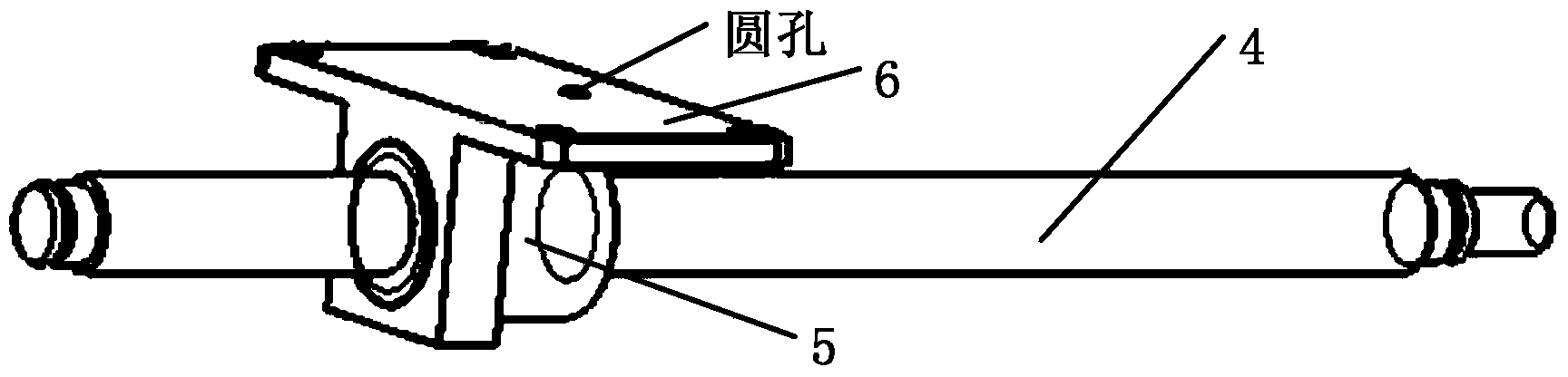

[0051] Such as figure 1 , 2 As shown, the magnetorheological high-precision positioning device of the present invention includes a fixed support mechanism, an outer circular positioning mechanism, and an end face positioning mechanism. The outer circular positioning mechanism passes through the guide rail 3, the first screw positioning frame 7, and the second screw positioning frame 8. Connected to the fixed support mechanism, the end face positioning mechanism is fixed on the positioning base 6 of the outer circle positioning mechanism through the end face positioning frame 14 .

[0052] Wherein: the fixed support mechanism, the model mainly includes a conical disc 1 and a chassis 2 . The conical disc 1 and the chassis 2 are connected as a whole by bolts, and the lower end surface of the conical disc 1 protrudes from two hubs, and the entire magnetorh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com