Electroplating and polishing grinding head with flexible layer

A polishing grinding and flexible layer technology, which is applied in the direction of grinding head, grinding/polishing equipment, grinding machine tool parts, etc., can solve the problems of cost, large positioning error, and change of the shape of the electroplating substrate, so as to reduce the use cost and achieve good The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

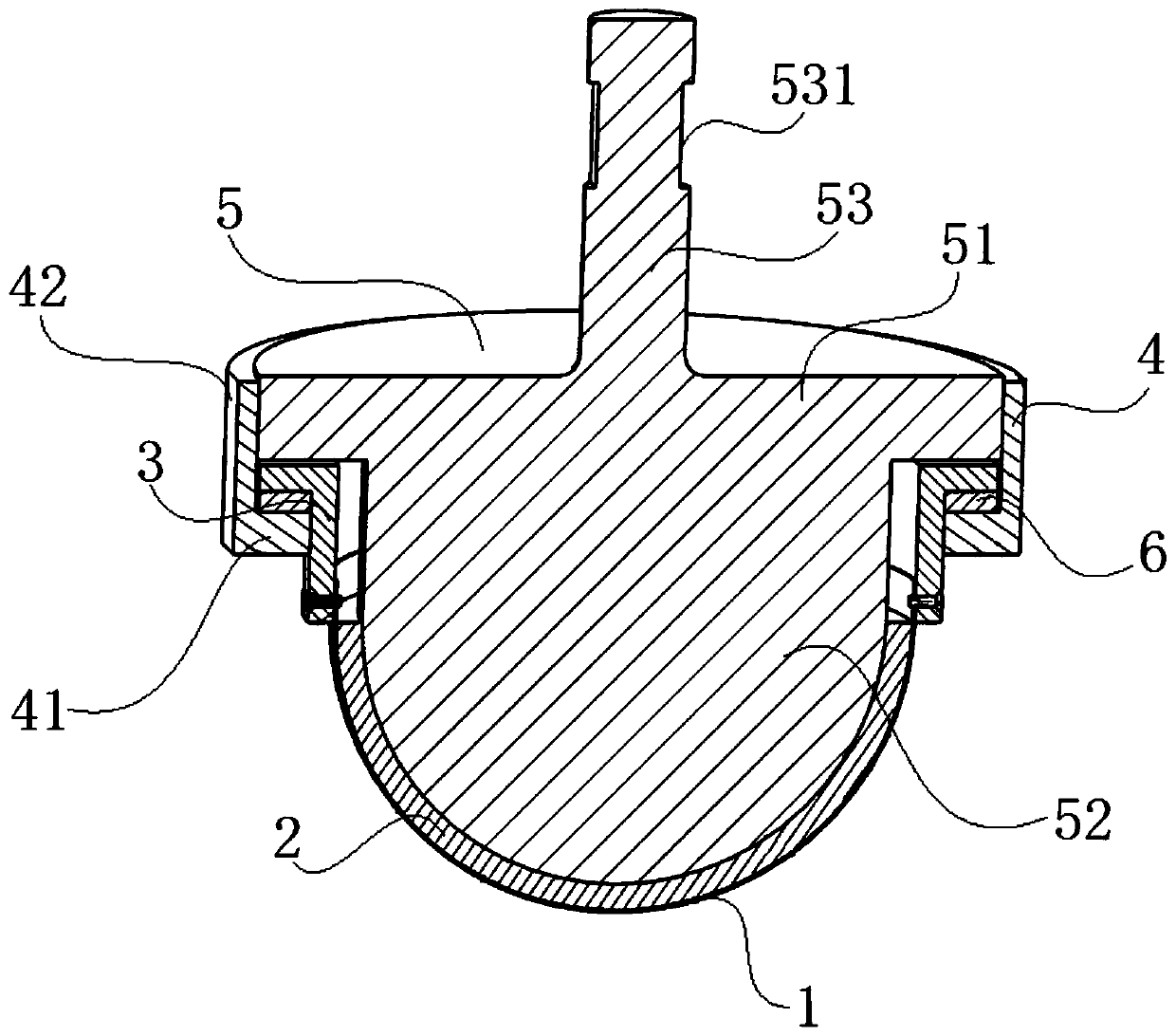

[0044] This embodiment discloses an electroplating polishing grinding head with a flexible layer, see Figure 1 to Figure 5 , including the metal outer layer 1 of the hemispherical shell, the flexible inner layer 2 of the hemispherical shell, the connecting seat cover 3 , the locking sleeve 4 and the rigid support seat 5 .

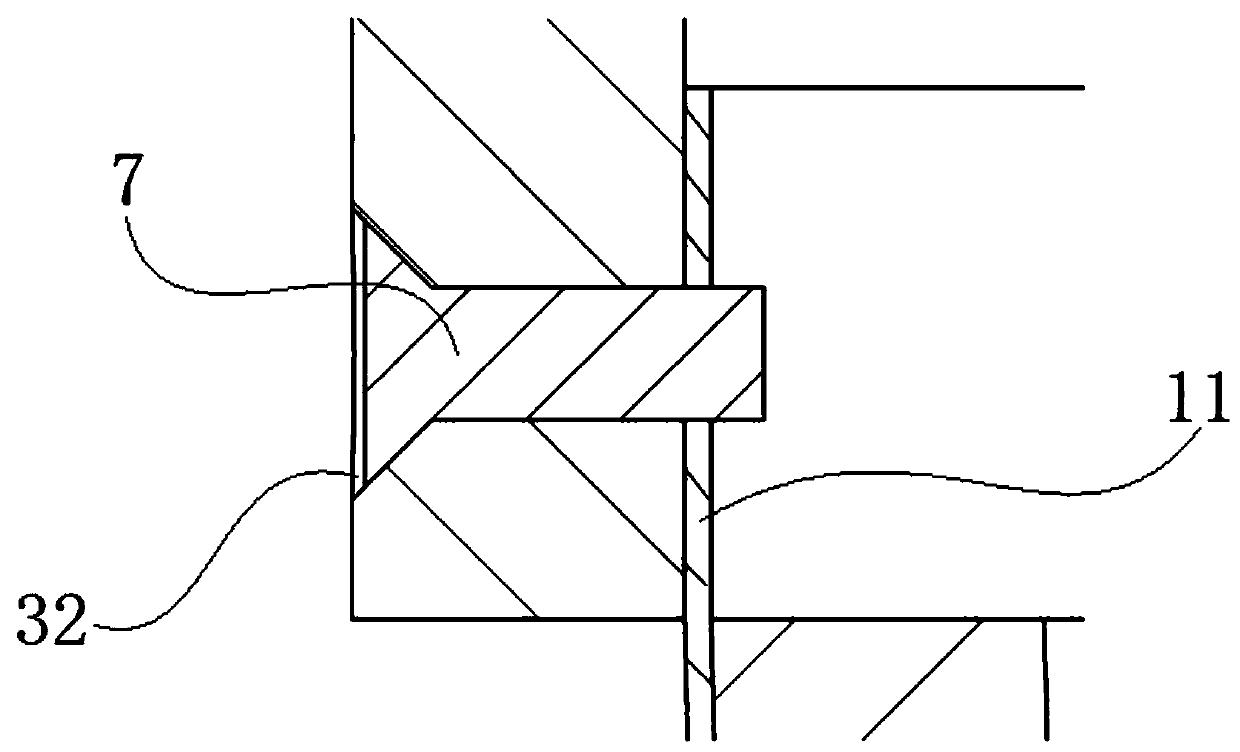

[0045] The metal outer layer 1 of the hemispherical shell is a hemispherical spring steel sheet or a mild steel sheet. The metal outer layer 1 of the hemispherical shell is formed by hot stamping. In this embodiment, the thickness of the metal outer layer 1 of the hemispherical shell is 0.3mm. The outer surface of the metal outer layer 1 of the hemispherical shell is electroplated with a polishing layer. A connecting portion 11 protrudes from the end surface of the metal outer layer 1 of the hemispherical shell. In this embodiment, the connecting portion 11 is a cylinder with a cylinder height of 8 mm, and two positioning holes 111 with a diameter of 1....

Embodiment 2

[0060] This embodiment discloses a relatively basic implementation method, an electroplating and polishing grinding head with a flexible layer, see Figure 1 to Figure 5 , including the metal outer layer 1 of the hemispherical shell, the flexible inner layer 2 of the hemispherical shell, the connecting seat cover 3 , the locking sleeve 4 and the rigid support seat 5 .

[0061] The outer surface of the metal outer layer 1 of the hemispherical shell is electroplated with a polishing layer. A connecting portion 11 protrudes from the end surface of the metal outer layer 1 of the hemispherical shell.

[0062] The flexible inner layer 2 of the hemispherical shell is attached to the inner metal outer layer 1 of the hemispherical shell. The structural rigidity of the flexible inner layer 2 of the hemispherical shell is greater than the structural rigidity of the metallic outer layer 1 of the hemispherical shell. The dimensional deformation elasticity of the flexible inner layer 2 of...

Embodiment 3

[0072] The main structure of this embodiment is the same as that of Embodiment 2. Further, a pre-tightened rubber gasket 6 is placed between the ring flange I31 and the ring flange II41.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com