Photocurable adhesive, polarizing plate, and laminate optical member

A light-curable, adhesive technology, applied in the direction of polarizing elements, optical elements, adhesive types, etc., can solve the problems of high moisture permeability, low moisture permeability, insufficient adhesive strength, etc., and achieve excellent thermal shock resistance , The storage modulus is improved, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2 and comparative example 1-9

[0175] (1) Preparation of photocurable adhesive

[0176] According to the proportion shown in Table 1 (unit is part), each component was mixed, and then degassed to prepare a photocurable adhesive solution. It should be noted that the photocationic polymerization initiator (b1) was blended in the form of a 50% propylene carbonate solution, and Table 1 indicated its solid content.

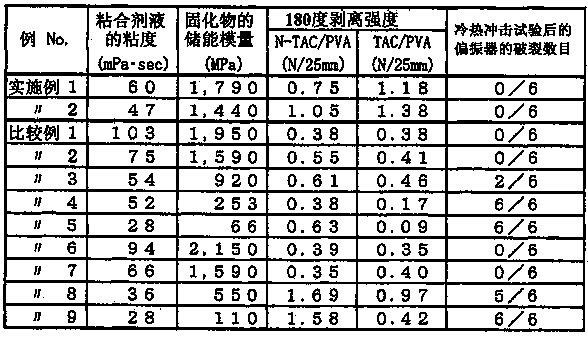

[0177] [Table 1]

[0178]

[0179] (2) Determination of the viscosity of the adhesive liquid at 25°C

[0180] The viscosity at a temperature of 25° C. was measured for each of the adhesive liquids prepared above using a rotary viscoelasticity measuring device “Physica MCR 301 ” manufactured by Anton Paar. The results are shown in Table 2.

[0181] (3) Determination of the storage modulus of the cured product at 80°C

[0182]Using a coater [bar coater, manufactured by Daiichi Rika Co., Ltd.], on a polyethylene terephthalate film [trade name "Toyobo Ester Film E7002E7002", manufactured by Toyob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com