Micro-indentation-based method for testing residual stress of tiny area of tough block material

A block material, residual stress technology, applied in the direction of testing material hardness, measuring force, measuring device, etc., can solve the problem of lack of effective measurement methods for tough block materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the metallographic sample is to use electrolytic polishing technology to polish the ductile bulk material to the mirror surface after grinding, and then perform shallow etching.

[0035] Step 2, perform micro-indentation test on the test sample block and the standard sample block to obtain the loading and unloading curve of the test sample block and the loading and unloading curve of the standard sample block, and analyze the loading and unloading curve to obtain the parameters for calculating the residual stress:

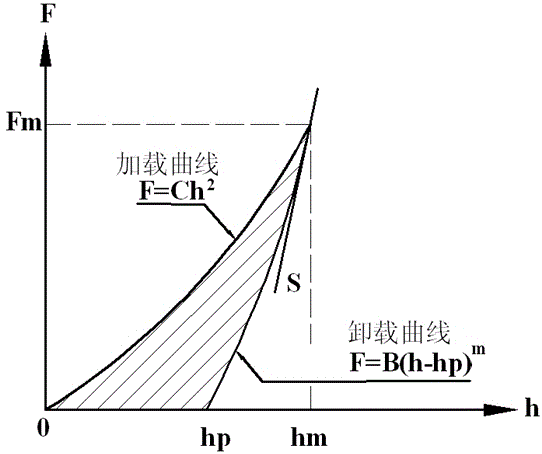

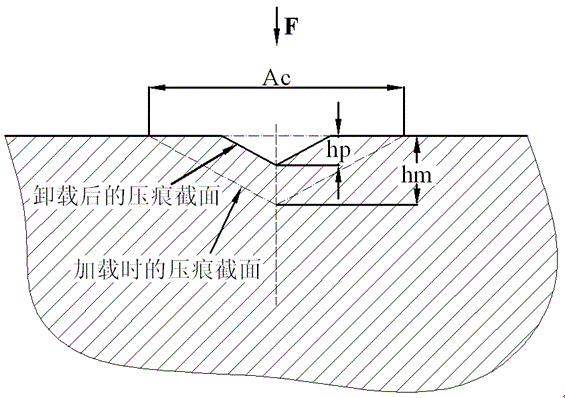

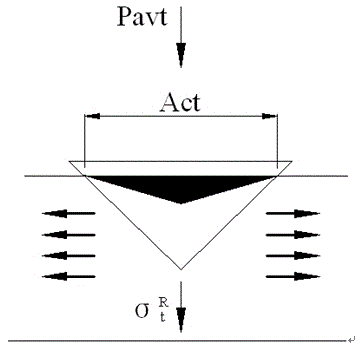

[0036] Step 2-1, obtain the indentation parameters of the loading and unloading curve of the test sample block and standard sample block: the load F at the maximum indentation depth m , the maximum pressure depth h m , the plastic deformation part of the indentation h p ;

[0037] Step 2-2, fitting the loading and unloading curve of the test sample, obtaining the material performance characterization reflected by the loading and u...

specific Embodiment 1

[0085] Specific Example 1: The test object is a large plastic deformation aluminum alloy 5052 prepared by the equal-diameter angular extrusion process. The original size of the extrusion sample is 10mm×10mm×60mm, and the center is cut at 10mm×10mm×6mm to complete the indentation method to measure the residual stress. In order to make the surface of the material mirror smooth, to facilitate the micro-indenter to press in to collect data, and to reduce the experimental error, the surface of the test piece needs to be prepared for metallography. First, it is ground with sandpaper, and then polished with electrolytic polishing. The defects affect the experimental results. The sample is shallowly etched to expose the grain boundary, and at the same time reduce the additional residual stress caused by mechanical grinding of the sample, avoid discontinuous defects when selecting test points, and improve the validity of test data. sex. During the test, keep the surface of the sample ...

specific Embodiment 2

[0093] Specific embodiment two: the test object is the local plastic deformation hole obtained by the slotted bushing hole extrusion process at room temperature, the material is aluminum alloy 7050, the hole diameter before extrusion is 5.4mm, and the hole diameter after extrusion is 6mm, the maximum plasticity The amount of strain was 11.11%. Due to local extrusion plastic deformation, the pore structure retains a large amount of residual stress. In order to make the surface of the material mirror smooth, it is convenient for the micro-indenter to press in to collect data, and to reduce the experimental error, the surface of the metallographic test piece is ground and polished. First, it is ground with sandpaper, and then polished with electrolytic polishing. Structural defects affect the experimental results, and the sample is shallowly etched to expose the grain boundaries, further reducing the additional residual stress caused by mechanical grinding of the metallographic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| strain hardening exponent | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com