Method for increasing leaching rate of copper in difficult-to-treat mineral

A difficult-to-handle and leaching rate technology, applied in the fields of acid leaching copper extraction and mineral roasting, can solve the problem of low copper recovery rate, and achieve the effect of significant economic benefits, simple process, and expanded processing adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

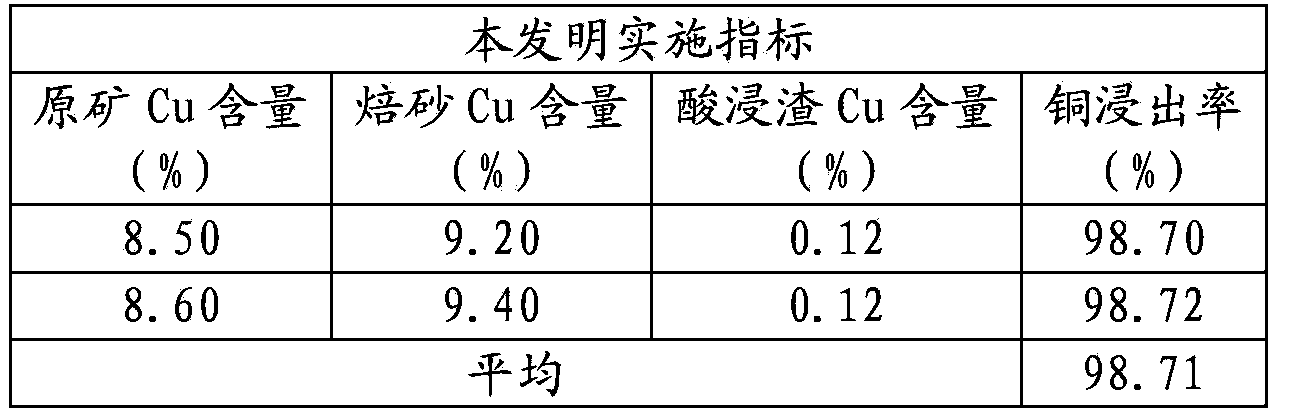

Embodiment 1

[0021] (1) Ore blending: According to the fineness and content analysis of refractory minerals such as copper, arsenic, and sulfur entering the plant, the ore blending is organized in the stockyard, so that the ore pulp contains 25% sulfur and 10% arsenic, and water and additives are added. Adjust the pulp concentration to 65%;

[0022] The additives added are sodium thiosulfate and manganese dioxide, the mixing mass ratio is 1:1, and the addition amount is 5%.

[0023] (2) Roasting: Spray the evenly stirred ore slurry into the roasting furnace with a spray gun. The roasting temperature is controlled at 580°C. Dust-containing flue gas is discharged through the top of the furnace and enters the secondary cooling dust collector. The first and second cooling dust collection The flue gas of the device passes through the bag filter to recover arsenic trioxide, and then produces 15% dilute sulfuric acid through wet dust collection, and the rest of the flue gas enters the acid system...

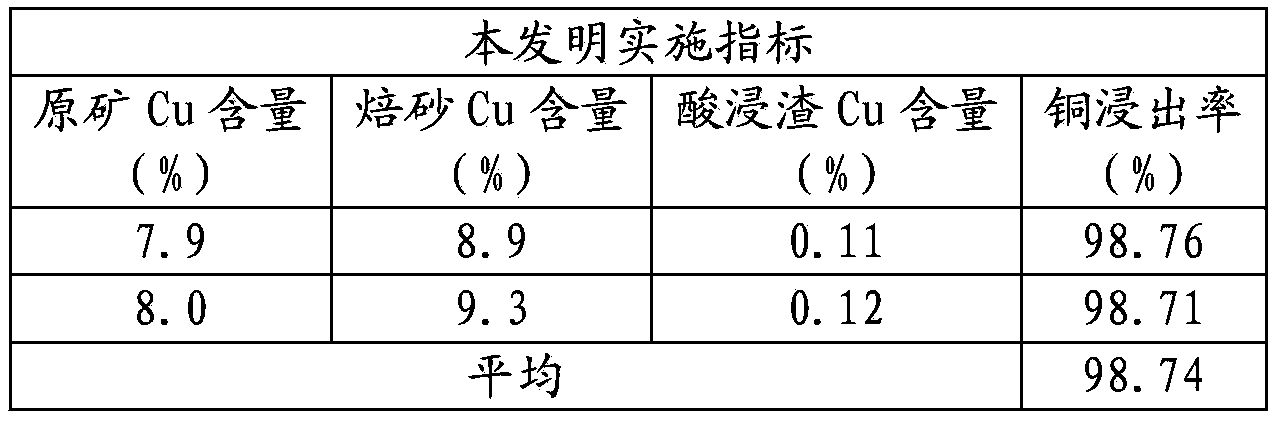

Embodiment 2

[0035] (1) Ore blending: According to the detection of fineness and content analysis of refractory minerals such as copper, arsenic, and sulfur entering the plant, the ore blending in the stockyard is organized so that the ore pulp contains 26% sulfur and 8% arsenic, and water and additives are added. Adjust the slurry concentration to 68%;

[0036] The additives added are sodium thiosulfate and manganese dioxide, the mixing mass ratio is 1:1, and the addition amount is 3%.

[0037] (2) Roasting: Spray the evenly stirred ore slurry into the roasting furnace with a spray gun. The roasting temperature is controlled at 590°C. Dust-containing flue gas is discharged through the top of the furnace and enters the secondary cooling dust collector. The first and second cooling dust collection The flue gas of the device passes through the bag filter to recover arsenic trioxide, and then produces 14% dilute sulfuric acid through wet dust collection, and the rest of the flue gas enters th...

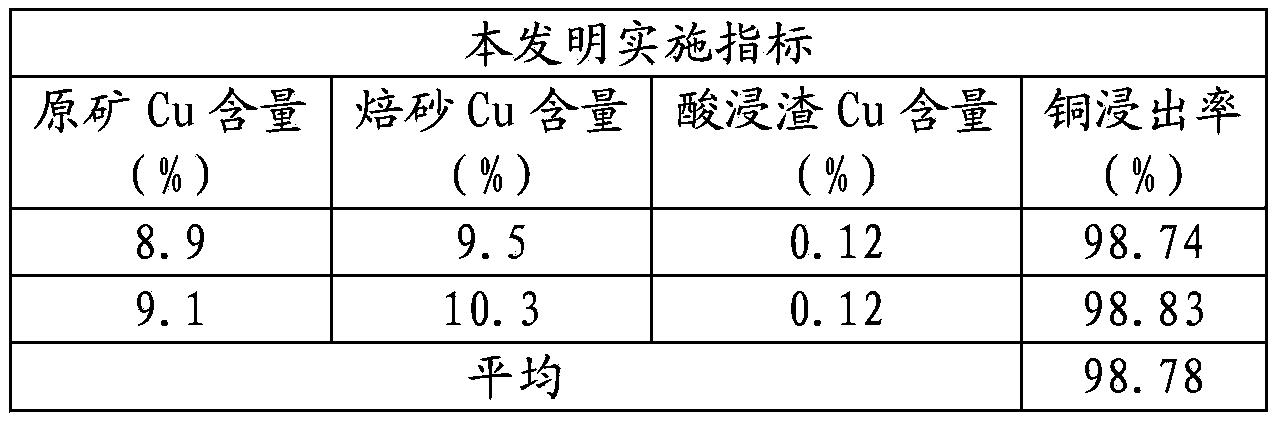

Embodiment 3

[0049] (1) Ore blending: According to the fineness and content analysis of refractory minerals such as copper, arsenic, and sulfur entering the plant, the ore blending is organized in the stockyard, so that the ore pulp contains 27% sulfur and 9% arsenic, and water and additives are added. Adjust the pulp concentration to 65%;

[0050] The additives added are sodium thiosulfate and manganese dioxide, the mixing mass ratio is 1:1, and the addition amount is 1%.

[0051] (2) Roasting: Spray the evenly stirred ore slurry into the roasting furnace with a spray gun. The roasting temperature is controlled at 600°C. Dust-containing flue gas is discharged through the top of the furnace and enters the secondary cooling dust collector. The first and second cooling dust collection The flue gas of the device passes through the bag filter to recover arsenic trioxide, and then produces 13% dilute sulfuric acid through wet dust collection, and the rest of the flue gas enters the acid system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com