Differential temperature heat treatment method for small diameter high chromium cast iron roll

A technology of differential temperature heat treatment and high chromium cast iron, applied in the field of heat treatment of rolls and differential temperature heat treatment, it can solve the problems of large furnace temperature fluctuation and inability to install the furnace, so as to improve the performance of the roll, reduce the fluctuation range, and improve the Markov range. Effects of Body Transformation Variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

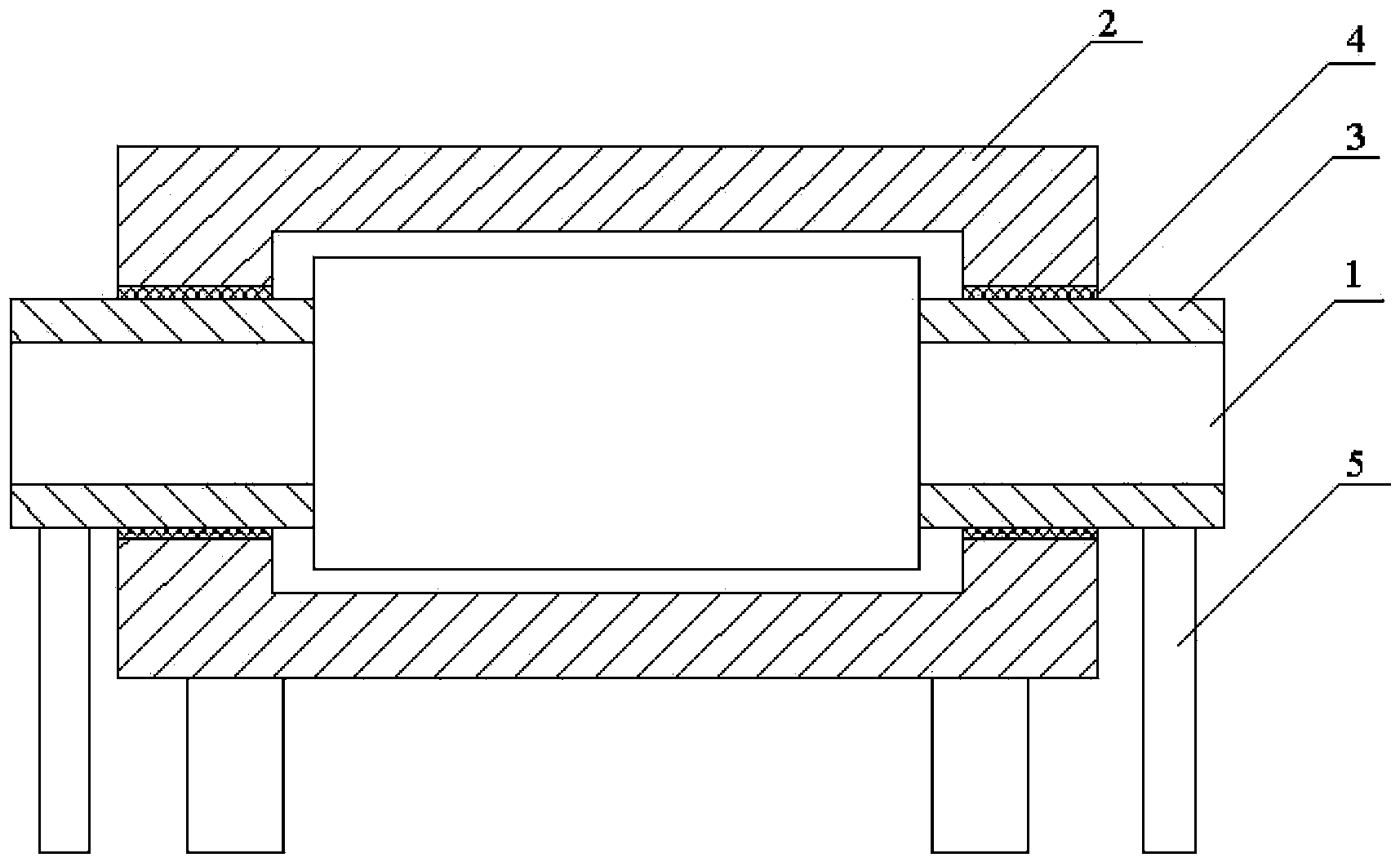

[0041] A differential temperature heat treatment method for small-diameter high-chromium cast iron rolls. In this embodiment, the differential temperature furnace 2 used is an MC3 horizontal differential temperature furnace. , Designed for rolls with a roll neck diameter of 350mm to 750mm. There are more than 30 burners arranged in the differential temperature furnace, and the burners in different positions have different air-fuel ratio standard values, that is, different air pressure standard values and gas pressure standard values. In general, the standard value of the air pressure of these burners is between 9Mpa and 12Mpa, and the standard value of the gas pressure is between 1.8Mpa and 2.4Mpa. In the present embodiment, the roll 1 to be processed is a high-chromium cast iron roll of the KmTBCr20Mo material, and its structure is as follows figure 2 As shown, the roll body 11 has a diameter of 550 mm and a length of 2000 mm, and the roll necks 12 at both ends of the roll ...

Embodiment 2~5

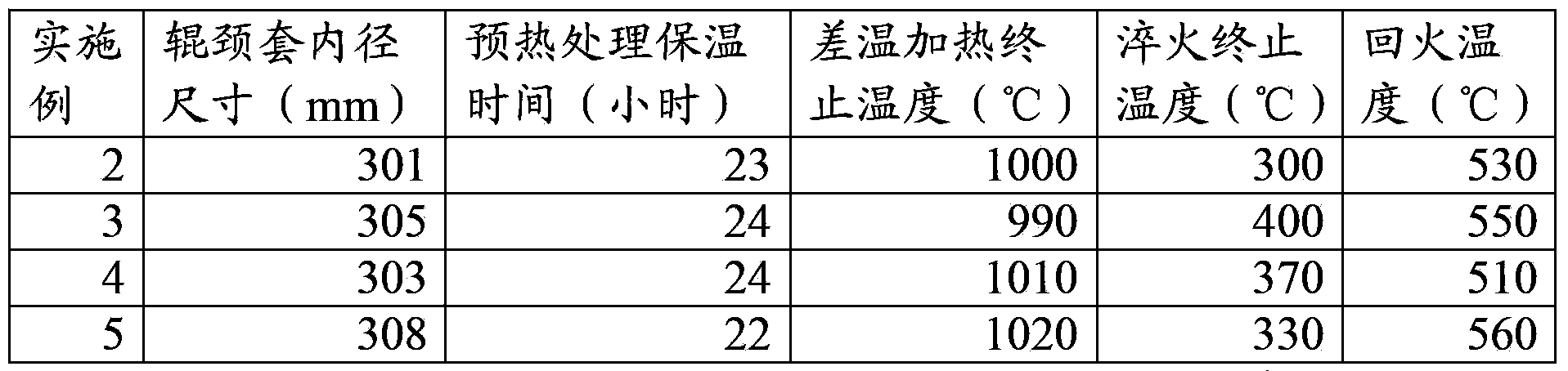

[0057] The difference with Example 1 is shown in the table below, and other conditions are the same.

[0058]

[0059] After testing, the fluctuating range of the furnace temperature has a certain correlation with the fit gap between the roll neck and the roll neck sleeve. When the fit gap is between 3 mm and 8 mm, the roll necks in Examples 2, 4, and 5 are adopted. When the inner diameter of the sleeve is set, the fluctuation range of the furnace temperature is between -3°C and +4°C, the fluctuation range is small, and the furnace performance is more stable. When the fitting gap is below 3 mm, the positive deviation of the furnace temperature is large, and the fluctuation range of the furnace temperature in Example 3 is between -2°C and +7°C. When the fit gap is above 8 mm, the negative deviation of the furnace temperature is relatively large, and the fluctuation range of the furnace temperature in Example 1 is between -6°C and +3°C. Therefore, the preferred fit clearance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com