Method for controlling size and distribution of metal surface micro-nanostructure

A micro-nano structure, metal surface technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as increasing the cost of processing equipment, limiting the size of the focusing spot, and limiting the control of the grating period, and achieves a wide range of metal types. , The production process is simple, and the processing depth is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

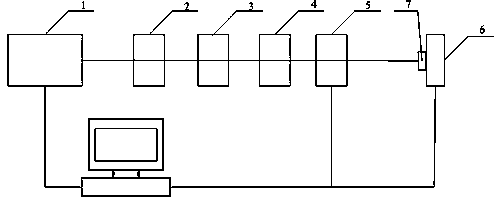

[0035] The metal sample in this embodiment is aluminum, and the aluminum sample is placed under the filament induced by the femtosecond pulse laser. The center wavelength of the femtosecond pulse laser selected in this example is 800nm, the repetition frequency is 1kHz, the pulse width is 50fs, and the horizontal line A polarized femtosecond laser with a single pulse energy of 3.5 mJ passes through a focusing lens with a focal length of 1 m to form a plasma filament about 11 cm in length. The sample is fixed on the three-dimensional translation stage, and the fixed direction of the translation stage is perpendicular to the plasma filament, so that the plasma filament can irradiate the surface of the metal sample vertically. The distance between the sample processing position and the focusing lens is 95cm. By moving the three-dimensional translation stage, the scanning speed is 5mm / s, change the scanning distance to 0.02mm-0.08mm, so as to control the distribution density and s...

Embodiment 2

[0037] The sample, laser parameters, and filamentation parameters used in this embodiment are the same as in Example 1. The sample is fixed on a three-dimensional translation platform, and the fixed direction of the translation platform makes the surface of the sample and the plasma filament be placed at an angle (90°, 75°, 60° , 45°), so that the plasma filament can be inclined to irradiate the surface of the metal sample, the distance between the sample processing position and the focusing lens is 95cm, the scanning speed of the translation stage is 4mm / s, and the scanning distance is 0.04mm. The angle between the plasma filament and the metal aluminum surface is used to control the pitch direction of the micro-nano structure on the metal aluminum surface, and the results are as follows Figure 4-7 shown.

Embodiment 3

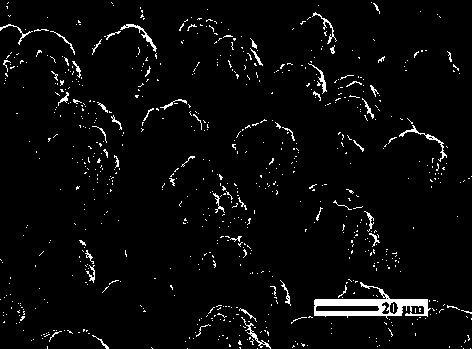

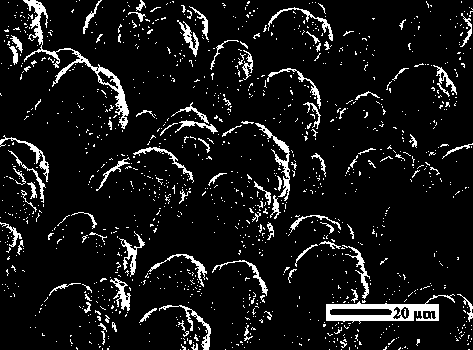

[0039] The sample, laser parameters, and filamentation parameters used in this embodiment are the same as in Example 1. The plasma filaments induced by circularly polarized and linearly polarized lasers with different polarization directions control the morphology of the micro-nanostructures on the aluminum surface. The results are as follows Figure 8-9 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com