Energy-saving and environment-friendly corrosion-preventing method of metal workpieces

A metal workpiece, energy-saving and environmental protection technology, applied in anti-corrosion coatings, chemical industry, surface pretreatment, etc., can solve the problems of long processing time, large workload, high cost, reduce emission costs, improve coating quality, connect compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] An energy-saving and environment-friendly metal workpiece anti-corrosion method comprises the following steps:

[0065] (1) Carry out degreasing and derusting treatment on the surface of the metal workpiece by degreasing and derusting agent:

[0066] With a gantry crane, immerse the metal workpiece (such as the metal casing of the filter) in a square degreasing and derusting tank filled with degreasing and derusting agent. Preferably, the inner layer of the degreasing and derusting tank is acid-resistant polytetrafluoroethylene board, and the outer layer is an insulating material layer. The degreasing and derusting treatment of metal workpieces is completed at 25°C through chemical reaction with degreasing and derusting agents. , the treatment time is 3 minutes, through observation, when the metal workpiece shows its metal color, the degreasing and derusting treatment is completed;

[0067] During the treatment process, on the one hand, a down-suction circulating filte...

Embodiment 2

[0099] An energy-saving and environment-friendly metal workpiece anti-corrosion method comprises the following steps:

[0100] (1) Carry out degreasing and derusting treatment on the surface of the metal workpiece by degreasing and derusting agent:

[0101] With a gantry crane, immerse the metal workpiece (such as the metal casing of the filter) in a square degreasing and derusting tank filled with degreasing and derusting agent. Preferably, the inner layer of the degreasing and derusting tank is acid-resistant polytetrafluoroethylene board, and the outer layer is an insulating material layer. The degreasing and derusting treatment of metal workpieces is completed at 20°C through chemical reactions using degreasing and derusting agents. , the treatment time is 10 minutes. Through observation, when the metal workpiece shows its metal color, the degreasing and rust removal treatment is completed;

[0102] During the treatment process, on the one hand, a down-suction circulating...

Embodiment 3

[0127] An energy-saving and environment-friendly metal workpiece anti-corrosion method comprises the following steps:

[0128] (1) Carry out degreasing and derusting treatment on the surface of the metal workpiece by degreasing and derusting agent:

[0129] With a gantry crane, immerse the metal workpiece (such as the metal casing of the filter) in a square degreasing and derusting tank filled with degreasing and derusting agent. Preferably, the inner layer of the degreasing and derusting tank is acid-resistant polytetrafluoroethylene board, and the outer layer is an insulating material layer. The degreasing and derusting treatment of metal workpieces is completed at 23°C through chemical reactions using degreasing and derusting agents. , the treatment time is 7 minutes. Through observation, when the metal workpiece shows its metal color, the degreasing and derusting treatment is completed;

[0130] During the treatment process, on the one hand, a down-suction circulating fil...

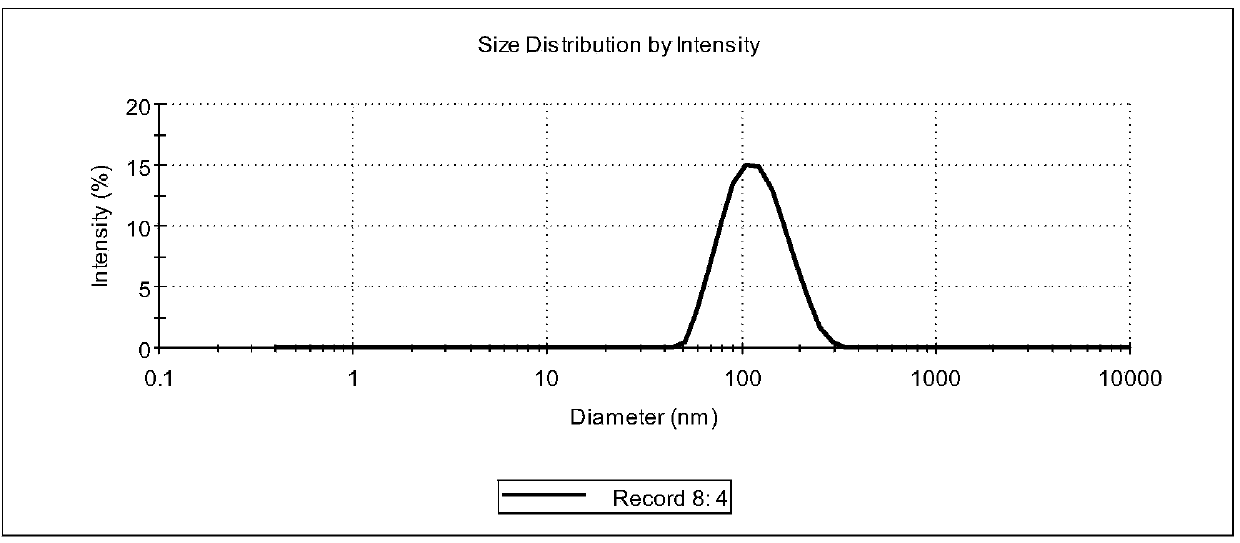

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com