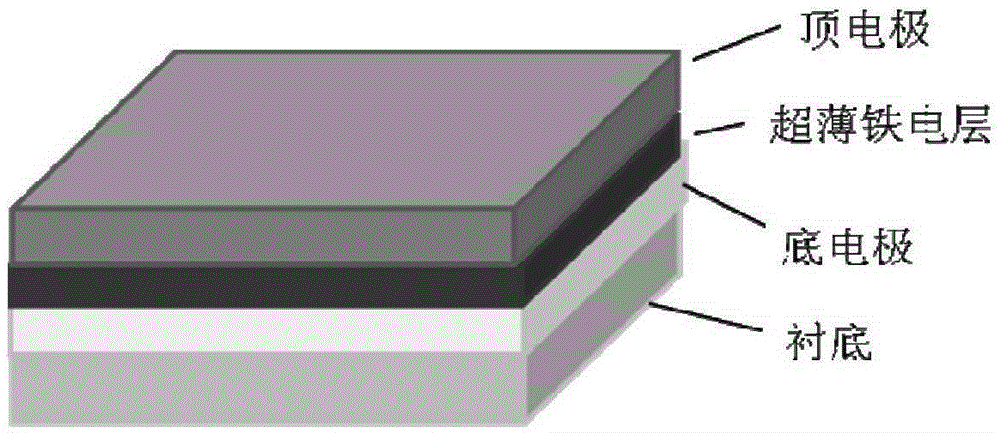

A piezoelectric memory cell based on ferroelectric tunnel junction and its preparation method

A technology of memory cells and ferroelectric tunnels, applied in the field of information storage, can solve the problems of difficult polarization reversal and poor retention, and achieve the effects of solving destructive reading, easy polarization reversal, and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Pt / Bi 3.15 Nd 0.85 Ti 3 o 12 / Pt ferroelectric tunnel junction piezoelectric memory unit, comprising the following steps:

[0028] (1) Preparation of Pt bottom electrode

[0029] The Pt metal bottom electrode was deposited on the Si substrate by vacuum evaporation coating method. In order to improve the adhesion between Pt and the substrate, Ti and SiO were also deposited between the Pt bottom electrode and the Si substrate. 2 Floor;

[0030] (2) Preparation of Bi by pulsed laser deposition method 3.15 Nd 0.85 Ti 3 o 12 ultrathin ferroelectric layer

[0031] In the vacuum chamber, the Bi 3.15 Nd 0.85 Ti 3 o 12 The target is installed on the multi-target rack, and the substrate with the Pt-plated bottom electrode is cleaned and installed on the substrate rack so that the direction of the laser beam is aligned with Bi 3.15 Nd 0.85 Ti 3 o 12 For the target, adjust the distance between the substrate and the target to 87mm. Turn on the mechan...

Embodiment 2

[0035] Preparation of Pt / BaTiO 3 / LaNiO 3 A ferroelectric tunnel junction piezoelectric memory cell, comprising the following steps:

[0036] (1)LaNiO 3 Preparation of bottom electrode

[0037] In a vacuum chamber, the LaNiO 3 The target is installed on the multi-target rack, and the Si substrate is cleaned and installed on the substrate rack so that the direction of the laser beam is aligned with the LaNiO 3 For the target, adjust the distance between the substrate and the target to 87mm. Turn on the mechanical pump and the molecular pump in sequence to pump the pressure in the vacuum chamber to 1*10 -7 mTorr. Turn on the KrF solid-state laser (laser wavelength is 248nm), adjust the energy of the single pulse of the laser to 320mJ, and the laser repetition rate is 10Hz; then feed oxygen into the vacuum chamber, and the oxygen pressure is fixed at 100mTorr, turn on the substrate heating device, and The substrate is heated up to 700°C; the laser beam emitted by the laser...

Embodiment 3

[0043] Preparation of Pt / BaTiO 3 / SrRuO 3 A ferroelectric tunnel junction piezoelectric memory cell, comprising the following steps:

[0044] (1)SrRuO 3 Preparation of bottom electrode

[0045] In a vacuum chamber, the SrRuO 3 The target is installed on the multi-target rack, and the Si substrate is cleaned and installed on the substrate rack so that the direction of the laser beam is aligned with the SrRuO 3 For the target, adjust the distance between the substrate and the target to 87mm. Turn on the mechanical pump and the molecular pump in sequence to pump the pressure in the vacuum chamber to 1*10 -7 mTorr. Turn on the KrF solid-state laser (laser wavelength is 248nm), adjust the energy of the single pulse of the laser to 320mJ, and the laser repetition rate is 10Hz; then feed oxygen into the vacuum chamber, and the oxygen pressure is fixed at 200mTorr, turn on the substrate heating device, and The substrate is heated to 700°C; the laser beam emitted by the laser is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com