Laser chemical order controllable preparation method of monocrystalline silicon inverted pyramid suede

An inverted pyramid and monocrystalline silicon technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complicated process steps and high equipment investment, and achieve the effects of simplified manufacturing process, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

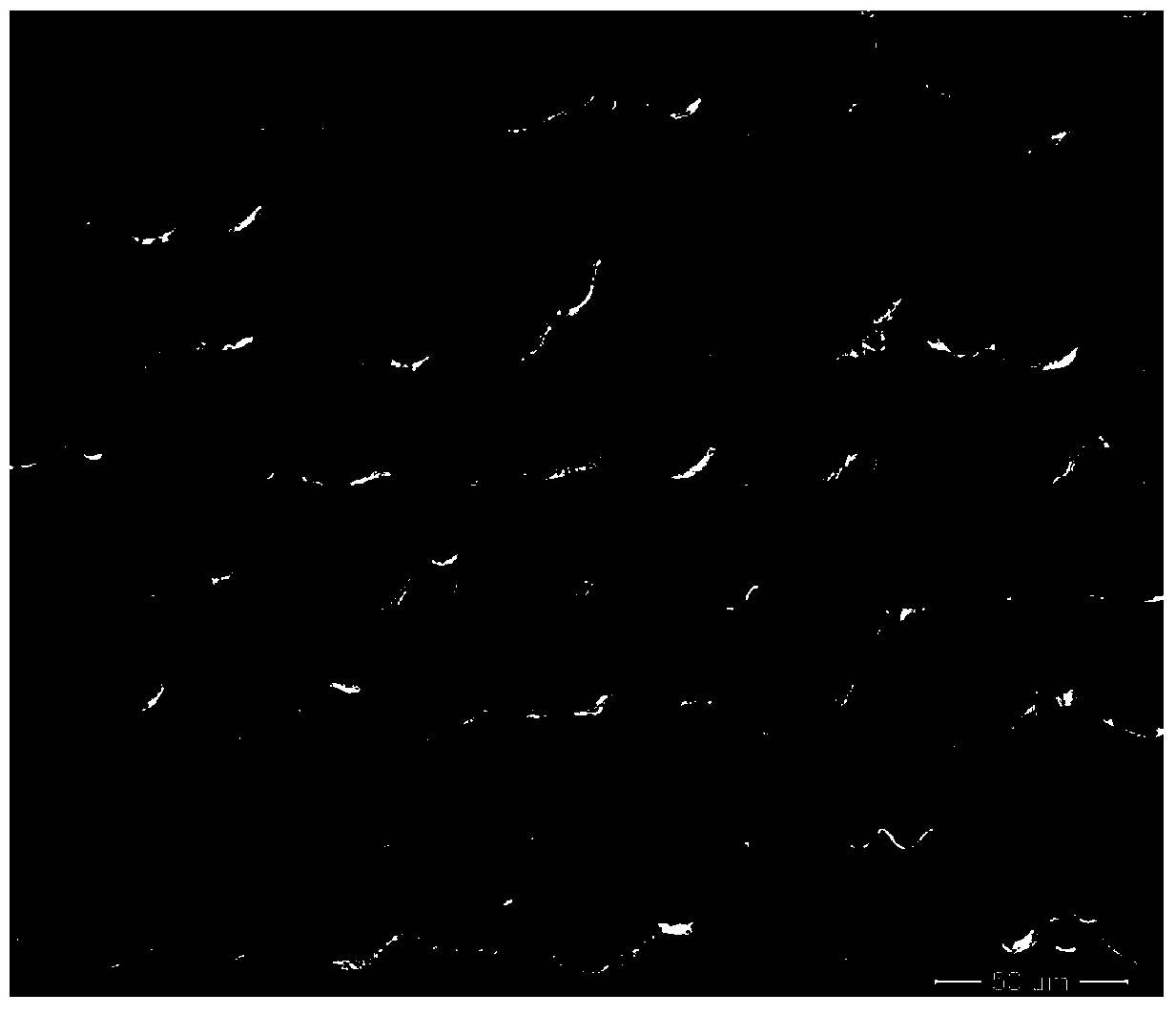

[0024] (1) Laser scanning opening positioning: use the focused 1064nm picosecond laser to scan the surface of the silicon wafer line by line, the diameter of the focused spot is 40 μm, the length of the scanning line is 8 mm, the scanning distance is 30 μm, and the energy density is 7.5 J / cm 2 , A=2.00*10 7 (Define A as the average number of pulses received per square centimeter on the surface of the silicon wafer), form evenly distributed inverted cone-shaped holes on the surface of the silicon wafer, with a diameter of about 30 μm, and finally obtain a square suede surface with a size of 8mm*8mm. Such as figure 1 ;

[0025] (2) pickling porous fleece layer: first rinse with HF acid with a volume fraction of 15% for 5 minutes to remove the generated oxides, then perform ultrasonic cleaning with distilled water for 5 minutes to remove debris, and then blow dry with nitrogen;

[0026] (3) Preparation of inverted pyramid suede: Put the pickled sample into the prepared alkaline...

Embodiment 2

[0032] (1) Preparation of hole-shaped suede surface: scan the surface of the silicon wafer line by line with a focused 1064nm picosecond laser, the diameter of the focused spot is 40 μm, the length of the scanning line is 8 mm, the scanning distance is 20 μm, and the energy density is 8.4 J / cm 2 , A=1.56*10 7 (Define A as the average number of pulses received per square centimeter on the surface of the silicon wafer), form evenly distributed inverted cone-shaped holes on the surface of the silicon wafer, with a diameter of about 20 μm, and finally obtain a square suede surface with a size of 8mm*8mm;

[0033] (2) pickling porous fleece layer: first rinse with HF acid with a volume fraction of 25% for 3 minutes to remove the generated oxides, then perform ultrasonic cleaning with distilled water for 3 minutes to remove debris, and then blow dry with nitrogen;

[0034] (3) Preparation of inverted pyramid suede: Put the pickled sample into the prepared alkaline solution and heat ...

Embodiment 3

[0040] (1) Preparation of hole-shaped suede: scan the surface of the silicon wafer line by line with a focused 1064nm picosecond laser, the diameter of the focused spot is 40 μm, the length of the scanning line is 8 mm, the scanning distance is 30 μm, and the energy density is 6.8 J / cm 2 , A=2.68*10 7 (Define A as the average number of pulses received per square centimeter on the surface of the silicon wafer), form evenly distributed inverted cone-shaped holes on the surface of the silicon wafer, with a diameter of about 30 μm, and finally obtain a square suede surface with a size of 8mm*8mm;

[0041] (2) pickling porous fleece layer: first rinse with HF acid with a volume fraction of 20% for 5 minutes to remove the generated oxides, then perform ultrasonic cleaning with distilled water for 5 minutes to remove debris, and then blow dry with nitrogen;

[0042] (3) Preparation of inverted pyramid suede: Put the pickled sample into the prepared alkaline solution and heat it in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com