Steel-plastic composite H-beam and production method thereof

A technology of steel-plastic composite and I-shaped beams, which is applied in the direction of slender components and building components, can solve the problems of easy oxidation and corrosion of the surface, poor surface finish and high cost, and achieve light weight, low production cost and high rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

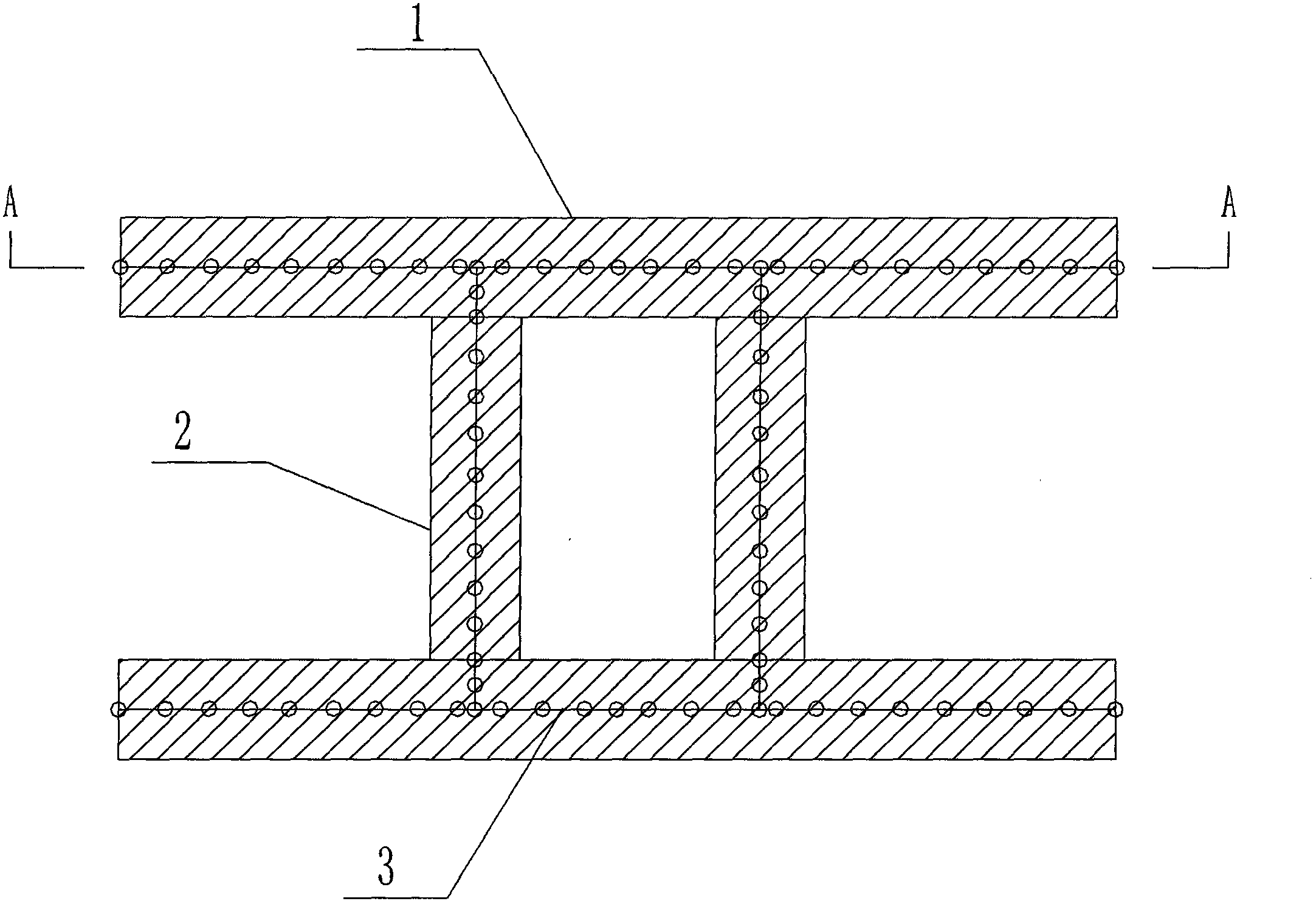

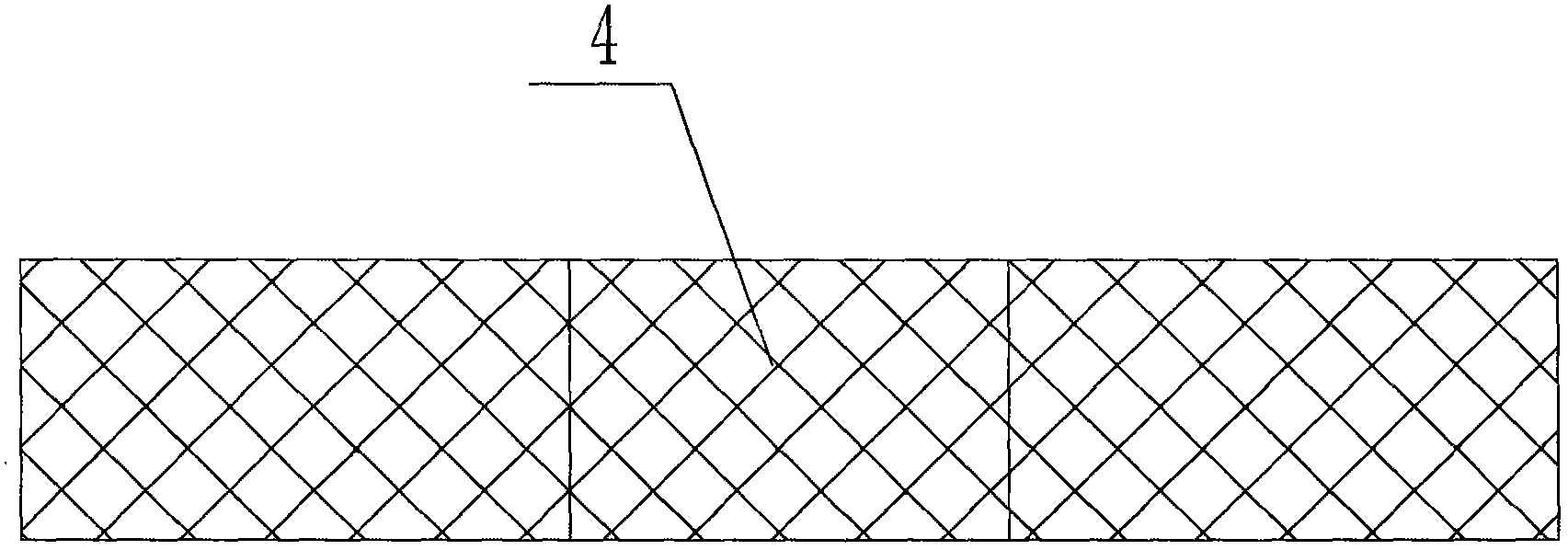

[0010] With reference to the accompanying drawings, the I-beam of the present invention comprises two parallel horizontal plates 1, between which two parallel horizontal plates are connected along the length direction of the horizontal plate with two mutually symmetrical with the center line of the horizontal plate. The parallel vertical boards 2, horizontal boards and vertical boards are all steel-plastic composite boards, and the steel-plastic composite boards are made of plastic and metal mesh compounded in the plastic.

[0011] The reference raw material ratio of the plastic material of the present invention is as follows:

[0012] 20-50 wt% of flame-retardant polypropylene, 40-70 wt% of polyethylene, 0.1-0.5 wt% of foaming agent, 0.1-0.5 wt% of lubricant, 0.1-0.3 wt% of flame retardant, and 5-10 wt% of wood powder.

[0013] Since the current plastic technology is very mature, the plastic material of the present invention is not limited to the above formula.

[0014] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com