Waterproof tensile optical cable

An optical cable and tensile technology, applied in the field of tensile optical cables, can solve the problems affecting the long-term stability of optical fiber transmission characteristics, poor mechanical properties of optical fibers, bending or breaking of optical fibers, etc. The effect of evenly distributing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

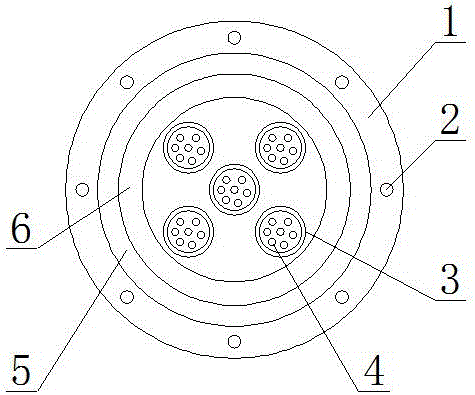

[0020] Such as figure 1 As shown, in this embodiment, a waterproof tensile optical cable includes an outer sheath 1, a waterproof layer 5 and an inner sheath 6 arranged sequentially from outside to inside, and several optical fiber sheaths are arranged in the inner sheath 6 3. Several optical fibers 4 are provided in the optical fiber sheath 3, and several reinforcing ribs 2 are provided in the outer sheath 1. The waterproof layer 5 is a waterproof casing made of waterproof yarn. By setting the reinforcing ribs 2, the Improve the tensile strength of the outer sheath 1, and improve its bending resistance when the optical cable is suspended in the air, so as to reduce the deflection of the optical cable and avoid the strong wind causing the optical cable to shake, which is beneficial to reduce the wear of the optical cable. When the optical cable is bent, the bending of the reinforcing rib 2 can also prevent the optical cable from returning to the state before the bending under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com