Underground coal mine ventilation and dust removal safety system

A technology of underground ventilation and safety system, which is applied in mine/tunnel ventilation, safety devices, and dust prevention. No dust, easy replacement and maintenance, enhanced dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

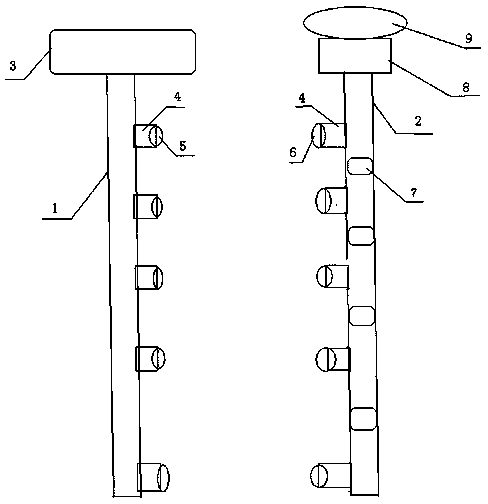

[0034] figure 1 It is an underground ventilation and dust removal safety system for coal mines according to the present invention. The system includes two bellows, two parallel bellows, the first bellows (1) and the second bellows (2), which are respectively arranged inside the mine. On both sides, the bellows are coated with self-luminous paint, and the two bellows extend from the outside of the mine to the bottom of the well;

[0035] The first bellows is connected with the blast device (3) outside the mine, and the blast device blows the purified air into the first bellows, and several tees (4) are arranged at intervals on the first bellows. ), the branch pipe of the three-way pipe perpendicular to the bellows is connected with an exhaust device (5), which blows the air in the bellows into the mine;

[0036] The second corrugated pipe is arranged in parallel with the first corrugated pipe, and several tees (4) are arranged at the place corresponding to the first corrugated...

Embodiment 2

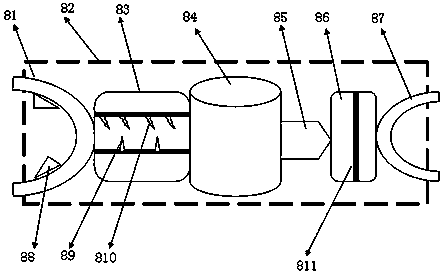

[0039] Such as figure 2 As shown, it is the integrated filter and dust removal device of the present invention in the daily working state, the integrated filter and dust removal device for coal mine safety of the present invention, and the integrated filter and dust removal device includes a fan, a housing, an adsorption filter part, a water vapor dust removal part, a bag dust removal part and dust Entrance;

[0040] After the dust inlet, the water vapor dust removal parts, bag dust removal parts, fan and adsorption filter parts are arranged in sequence, and the housing is located outside the entire integrated filter dust removal device;

[0041] The water vapor dedusting part is used for preliminary water vapor dedusting of the dust collected from the dust inlet into the integrated filter dedusting device; the bag dust removal part is used for bag dedusting of the dust particles that still exist in the gas after being treated by the water vapor dedusting part ;

[0042] Th...

Embodiment 3

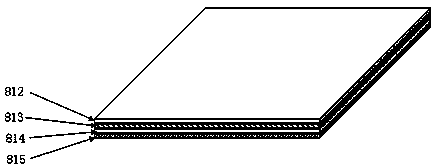

[0049] Such as image 3 The filter membrane of the shown adsorption filter part is a layered structure, which is composed of an outer layer, an inner layer and an intermediate layer respectively, and the intermediate layer includes a filter layer; the filter layer includes the first honeycomb photocatalyst filter screen layer, the first solid-carried nano-titanium dioxide filter layer positioned at one side of the honeycomb photocatalyst filter layer, the second honeycomb photocatalyst filter layer positioned at the other side of the first solid-carried nano-titanium dioxide filter layer, and the The second solid-loaded nano-titanium dioxide filter layer on the other side of the second honeycomb photocatalyst filter layer, the aperture of the first honeycomb photocatalyst filter layer is 0.98mm, and the thickness is 0.88mm; the second honeycomb photocatalyst The aperture of the filter screen layer is 0.79mm, and the thickness is 0.89mm; the volume content of activated carbon i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com