Construction method for reinforced concrete prefabricated house

A reinforced concrete and prefabricated assembly technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of high construction cost, unreasonable structure, and difficulty in popularization, so as to improve construction efficiency, reduce engineering cost, and improve construction efficiency. The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

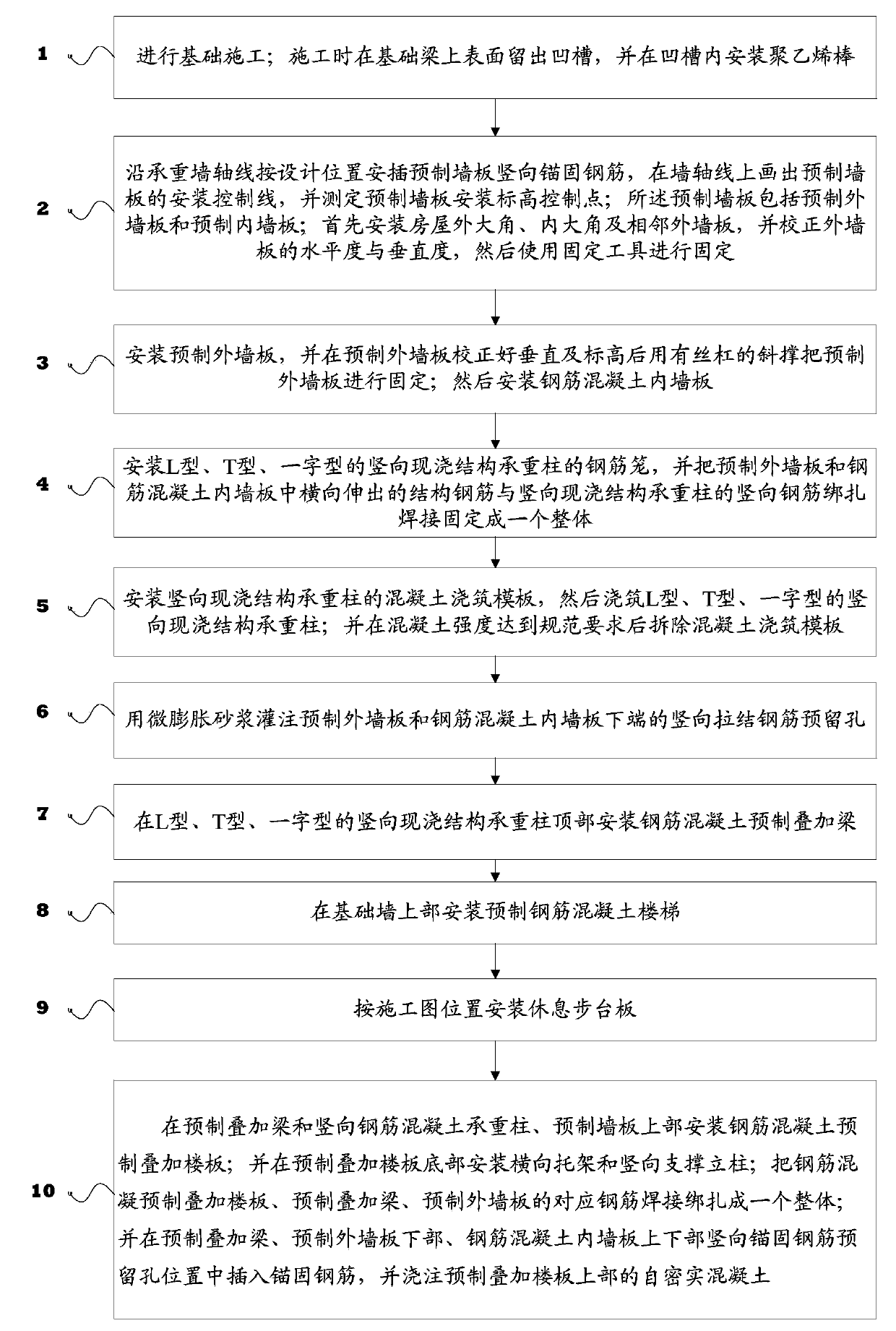

[0066] The embodiment of the present invention proposes a construction method for a reinforced concrete prefabricated house, the process of which is as follows figure 1 shown, including:

[0067] Carry out foundation construction; leave a groove on the upper surface of the foundation beam during construction, and install polyethylene rods in the groove;

[0068] Install the vertical anchoring steel bar of the prefabricated wallboard according to the design position along the axis of the load-bearing wall, draw the installation control line of the prefabricated wallboard on the wall axis, and measure the control point of the installation elevation of the prefabricated wallboard; the prefabricated wallboard includes the prefabricated outer wallboard And p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com