Formaldehyde-purifying alkyd resin and preparation method thereof

An alkyd resin and formaldehyde technology, applied in coatings, polyester coatings, etc., can solve the problems of unsuitable promotion of biological purification methods, affecting the light transmittance of resins, and unclear mechanism of formaldehyde, achieving low toxicity and practicability. Strong and fluid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

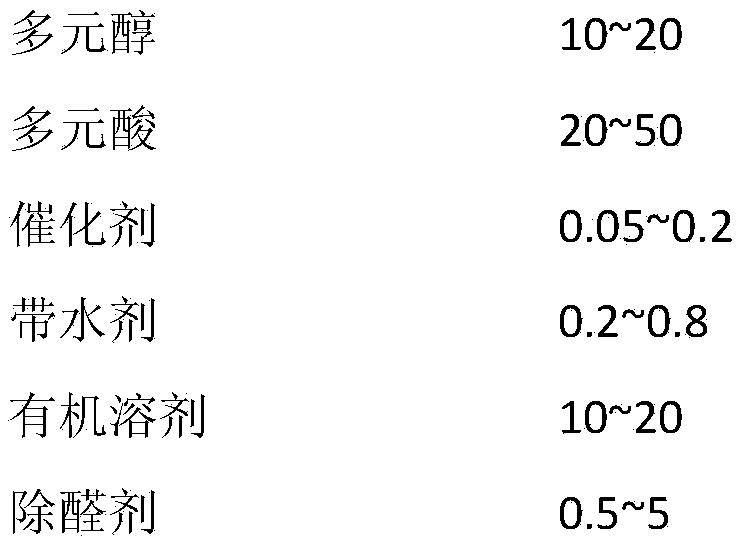

[0042] In parts by weight, prepare and purify formaldehyde alkyd resin according to the following composition:

[0043]

[0044] The preparation method of purifying formaldehyde alkyd resin, its operation steps are as follows:

[0045] (1) Under the protection of nitrogen, put glycerin, soybean oil fatty acid and phthalic anhydride into the reaction kettle in sequence, and raise the temperature to 100°C;

[0046] (2) Add p-toluenesulfonic acid, start stirring, raise the temperature to 220°C, and keep it warm for 2 hours;

[0047] (3) Cool down to 200°C, add cyclohexane, heat up to 250°C and reflux for 3 hours until the acid value is less than 7;

[0048] (4) Add ethyl acetate and butyl acetate, mix well to obtain alkyd resin;

[0049] (5) Add N‐β‐(aminoethyl)‐γ‐aminopropyltrimethoxysilane to the alkyd resin, react at 50°C for 10 minutes, and disperse evenly.

Embodiment 2

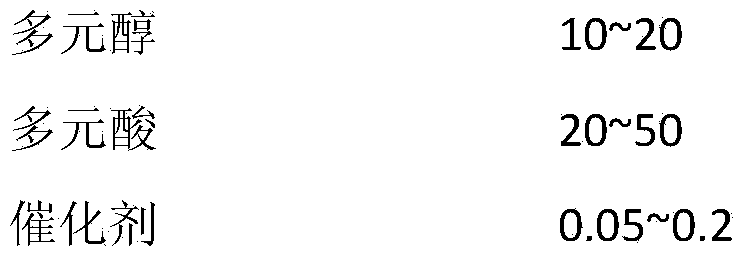

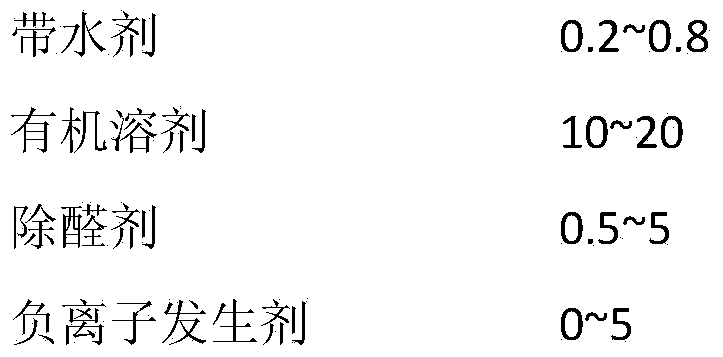

[0051] In parts by weight, prepare and purify formaldehyde alkyd resin according to the following composition:

[0052]

[0053]

[0054] The preparation method of purifying formaldehyde alkyd resin comprises steps as follows:

[0055] (1) Under the protection of nitrogen, put glycerin, castor oil fatty acid and phthalic anhydride into the reaction kettle in sequence, and raise the temperature to 130°C;

[0056] (2) Add p-toluenesulfonic acid, start stirring, raise the temperature to 260°C, and keep it warm for 1 hour;

[0057] (3) Cool down to 220°C, add cyclohexane, heat up to 280°C and reflux for 1 hour until the acid value is less than 7;

[0058] (4) Add 200# solvent oil and mix well to obtain alkyd resin;

[0059] (5) Add adipic acid dihydrazide to the alkyd resin and react at 55°C for 15 minutes to obtain a modified alkyd resin;

[0060] (6) Add nano-silica and aluminum oxide to the modified alkyd resin, and disperse evenly to obtain the product.

Embodiment 3

[0062] In parts by weight, prepare and purify formaldehyde alkyd resin according to the following composition:

[0063]

[0064] The preparation method of purifying formaldehyde alkyd resin, its operation steps are as follows:

[0065] (1) Under the protection of nitrogen, put glycerin, soybean oil fatty acid and maleic anhydride into the reaction kettle in sequence, and raise the temperature to 130°C;

[0066] (2) Add solid acid, start stirring, raise the temperature to 220°C, and keep it warm for 3.5 hours;

[0067] (3) Cool down to 210°C, add propyl acetate, heat up to 265°C and reflux for 1.5 hours until the acid value is less than 7;

[0068] (4) Add butyl acetate and mix well to obtain alkyd resin;

[0069] (5) Add polyamide to the alkyd resin and react at 25°C for 3 minutes to obtain a modified alkyd resin;

[0070] (6) Add nano silicon dioxide to the modified alkyd resin, and disperse evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com