Material used for manufacturing foam cement, method for preparing foam cement from same, and foam cement

A foamed cement and cement technology, which is applied in the field of foamed cement products, can solve the problems of unsatisfactory comprehensive performance, decreased closed cell ratio of foamed cement materials, and no consideration, and achieves low water absorption, good performance, and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

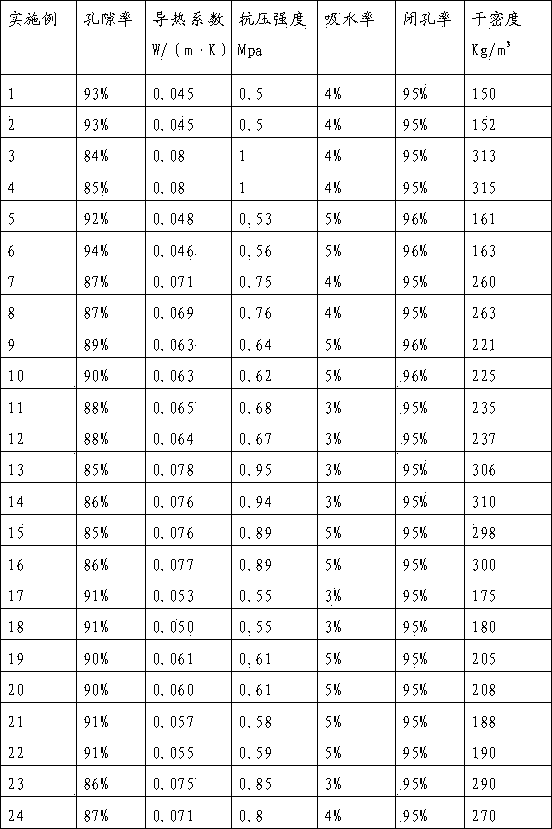

Examples

Embodiment 1

[0054] This embodiment provides a material for producing foamed cement, including the following components by weight: cement: 100 parts by weight, solid waste materials: 20 parts by weight, cell regulator: 2.5 parts by weight, cell wall reinforcement Agent: 0.1 parts by weight, foaming agent: 15 parts by weight, foaming speed regulator: 0.002 parts by weight, curing speed regulator: 0.5 parts by weight, water: 62 parts by weight.

[0055] Among them, the cement used is sulfoaluminate cement, the solid waste material used is fly ash, the cell regulator used is calcium stearate, the cell wall strengthening agent used is polycarboxylate, and the foaming agent used is hydrogen peroxide. The foaming speed regulator used is PP powder, the curing speed regulator used is boric acid, and the water used is tap water.

[0056] The method for preparing foamed cement by utilizing the above-mentioned foamed cement material comprises the steps in turn:

[0057] 1) Start the mixer and put 62...

Embodiment 2

[0066] This embodiment is an improvement on the basis of Example 1, the difference is: when proportioning the component raw materials, talcum powder and fly ash are added in the cell regulator, and the cell regulator is mixed with talcum powder and pulverized coal Ash is mixed in a ratio of 1:1:3; and when preparing foamed cement, the above-mentioned cell regulator mixed with talcum powder and fly ash is used to replace the original simple cell regulator.

Embodiment 3

[0068] This embodiment provides a material for producing foamed cement, which is composed of the following components by weight, specifically including: cement: 100 parts by weight, solid waste material: 80 parts by weight, cell regulator: 1.2 parts by weight Parts, cell wall reinforcing agent: 0.5 parts by weight, foaming agent: 2.5 parts by weight, foaming speed regulator: 0.023 parts by weight, curing speed regulator: 0.01 parts by weight, water: 93 parts by weight.

[0069] Among them, the cement used is Portland cement, the solid waste material used is a mixture of construction waste powder, tailings powder and mineral powder, the cell regulator used is zinc stearate, and the cell wall enhancer used is lignosulfonic acid Calcium, the foaming agent used is magnesium powder, the foaming speed regulator used is potassium chlorate, the curing speed regulator used is lithium carbonate, and the water used is middle water.

[0070] The method for preparing foamed cement by utili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com