Laser amplifier

A technology of laser amplifiers and laser crystals, which is applied to lasers, laser components, phonon exciters, etc., can solve the problem of low output power, low overlapping efficiency of seed light and pump gain regions, and low extraction efficiency of laser amplifiers etc. to achieve the effects of low cost, improved efficiency and energy utilization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

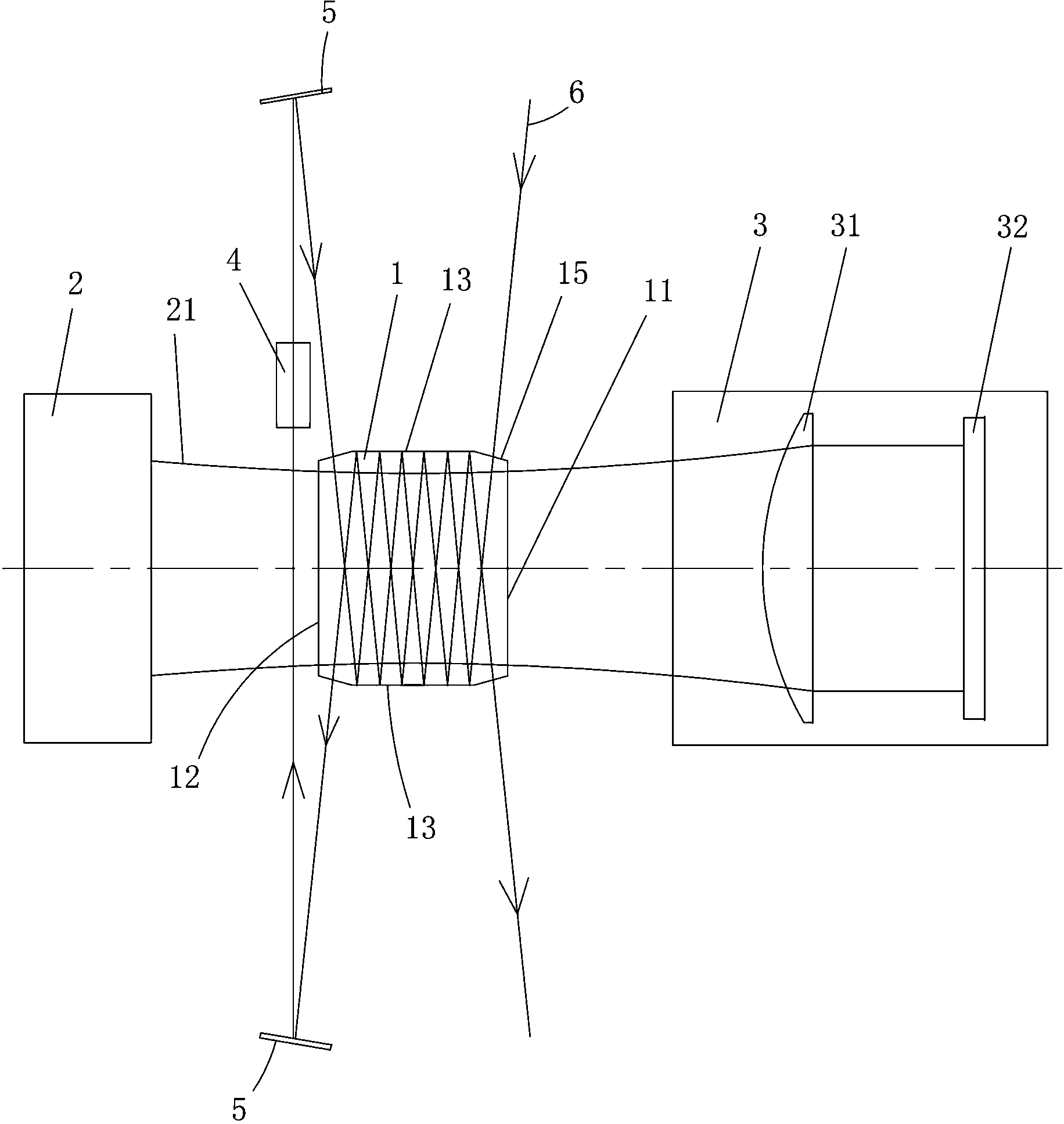

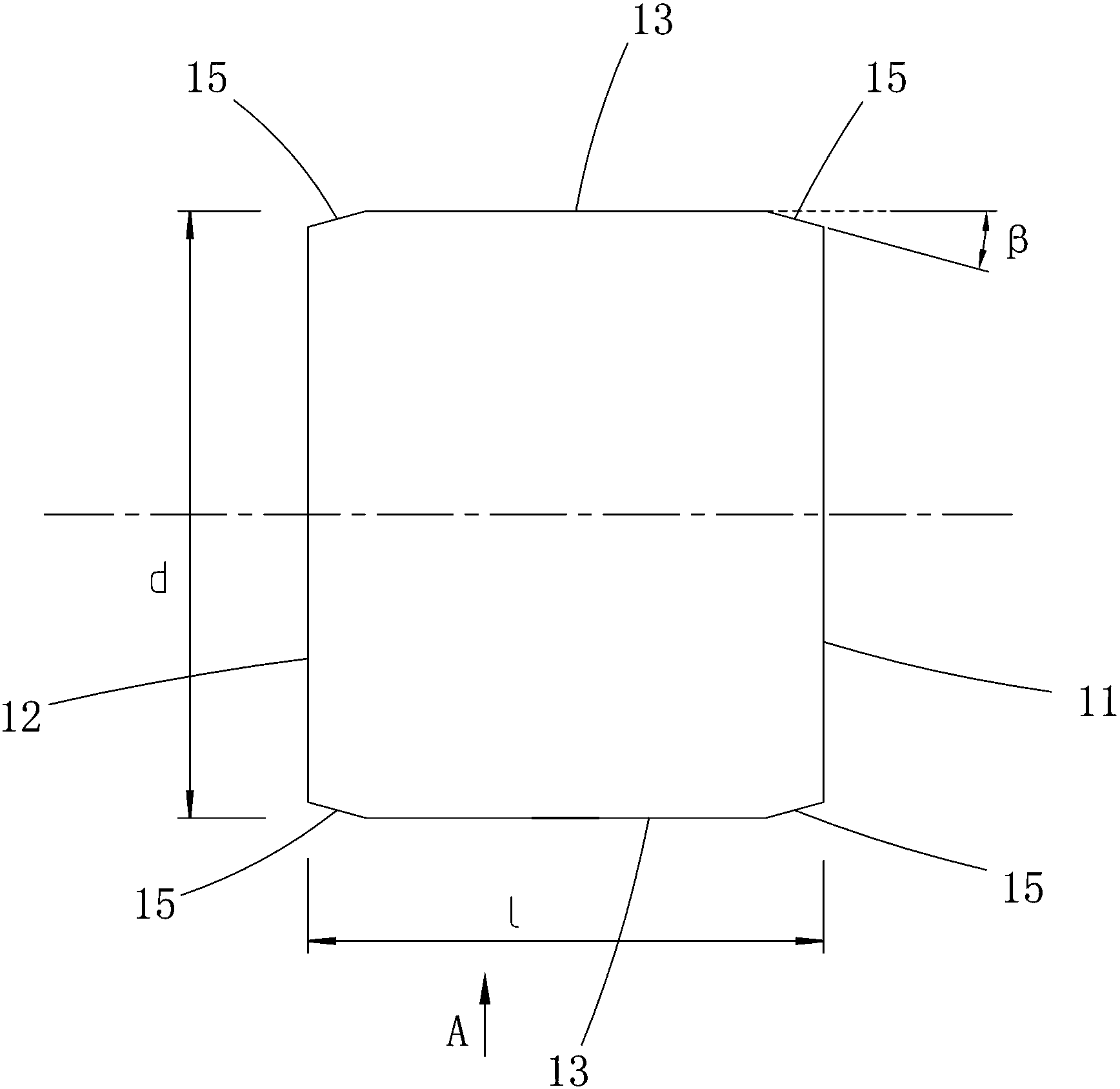

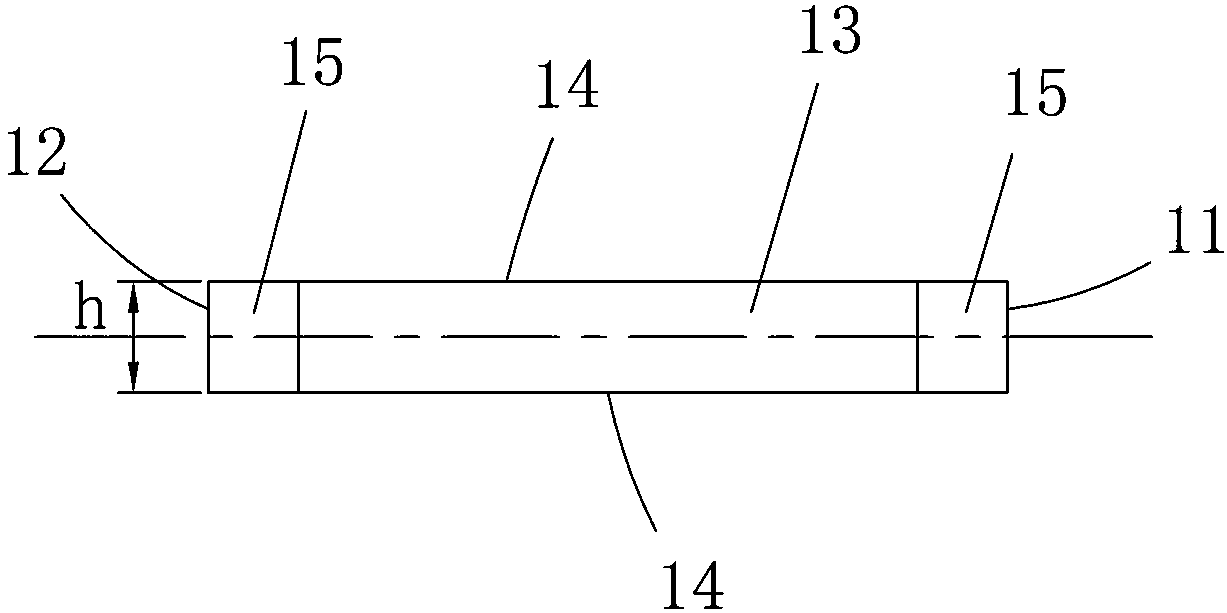

[0031] Such as figure 1 As shown, the laser amplifier of the present invention includes a pumping system 2 and a slab laser crystal 1, the pumping system 2 is used to pump the slab laser crystal 1, and the slab laser crystal 1 absorbs the pump light 21 to cause the number of particles Inversion, the energy stored in the slab laser crystal 1 forms a gain region. The two ends in the length direction of the slab laser crystal 1 are respectively the first end 11 and the second end 12, the two sides in the width direction of the slab laser crystal 1 are total reflection surfaces 13, and the two sides in the thickness direction of the slab laser crystal 1 are for the heat sink surface 14 (see image 3 ). The heat dissipation surface 14 adopts a commonly used copper water cooling device, and the heat dissipation surface 14 and the copper are in close contact with each other through indium. One side of the end face of the second end 12 is provided with a mirror assembly. During ope...

Embodiment 2

[0042] Such as Figure 6 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, except that the size of the slab laser crystal 1 is l=11.5 mm in length, d=12 mm in width, and h=2 mm in thickness. Because the length of slab laser crystal 1 is different from embodiment 1, the number of reflections of seed light 6 in slab laser crystal 1 is also different from embodiment 1 (the reflection principle of seed light is the same as embodiment 1, and here No longer).

Embodiment 3

[0044] Such as Figure 7 , Figure 8 As shown, the difference between the structure of this embodiment and embodiment 1 is that the material of slab laser crystal 1 is Nd:YVO 4 , the size of the slab laser crystal 1 is l=12.5mm in length, d=10.2mm in width, h=2mm in thickness, and the doping concentration is 1%. The crystal is α Direction cut, length 12.5mm for c axis direction. The pumping system 2 and the pumping light reflection matching system 3 are respectively arranged on both sides of the width direction of the slab laser crystal.

[0045] In this embodiment, the included angle β is 7 degrees, and the projected length of the cut surface 15 on the corresponding total reflection surface 13 is 1.25 mm. The total reflection surface 13 is coated with a pump light high-transmission film and a seed light high-reflection film, and the cut surface 15 is coated with a seed light high-transmission film.

[0046] The pump light with a central wavelength of 888nm enters the sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com