Method for preparing MnO2/carbon composite material for super-capacitor

A technology of carbon composite materials and supercapacitors, applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of limited precious metal resources, high prices, restricted use, etc., and achieve a high specific capacity that is conducive to popularization and application , the effect of increasing the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment includes the following steps:

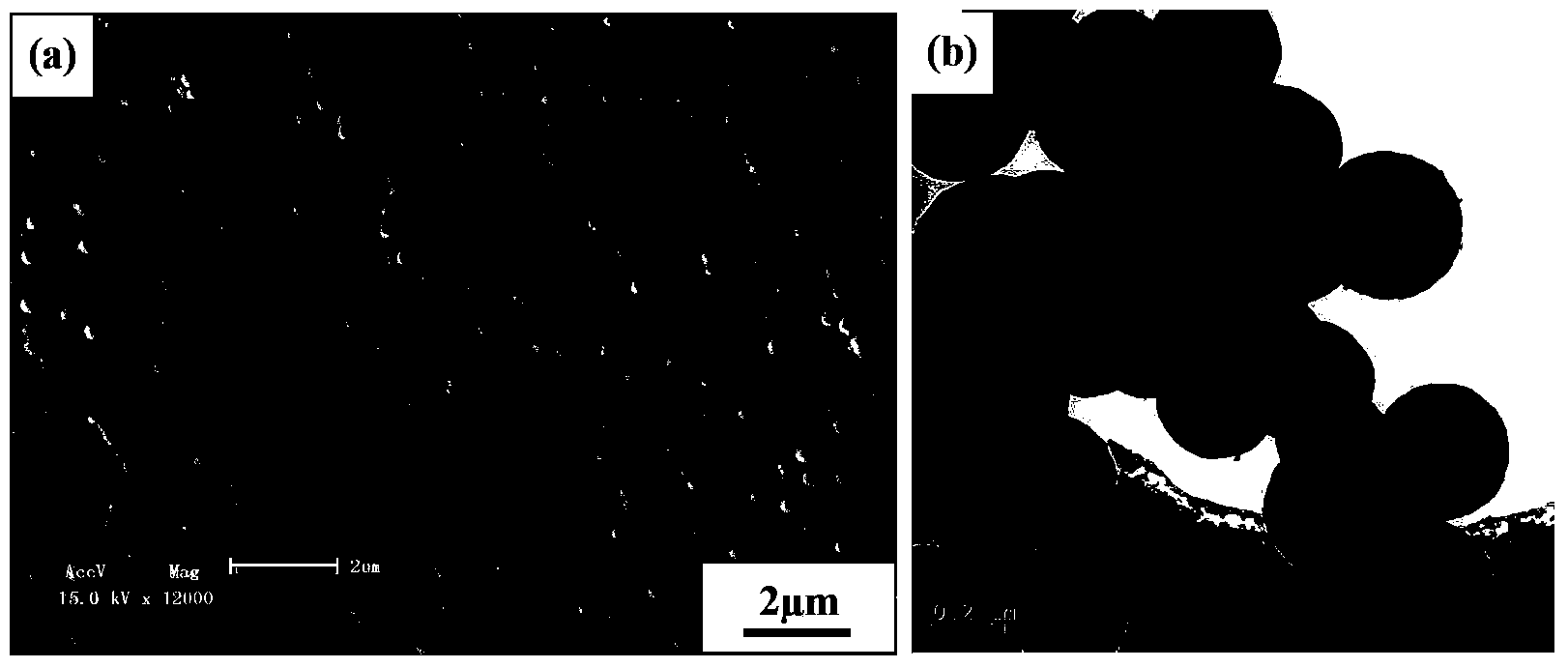

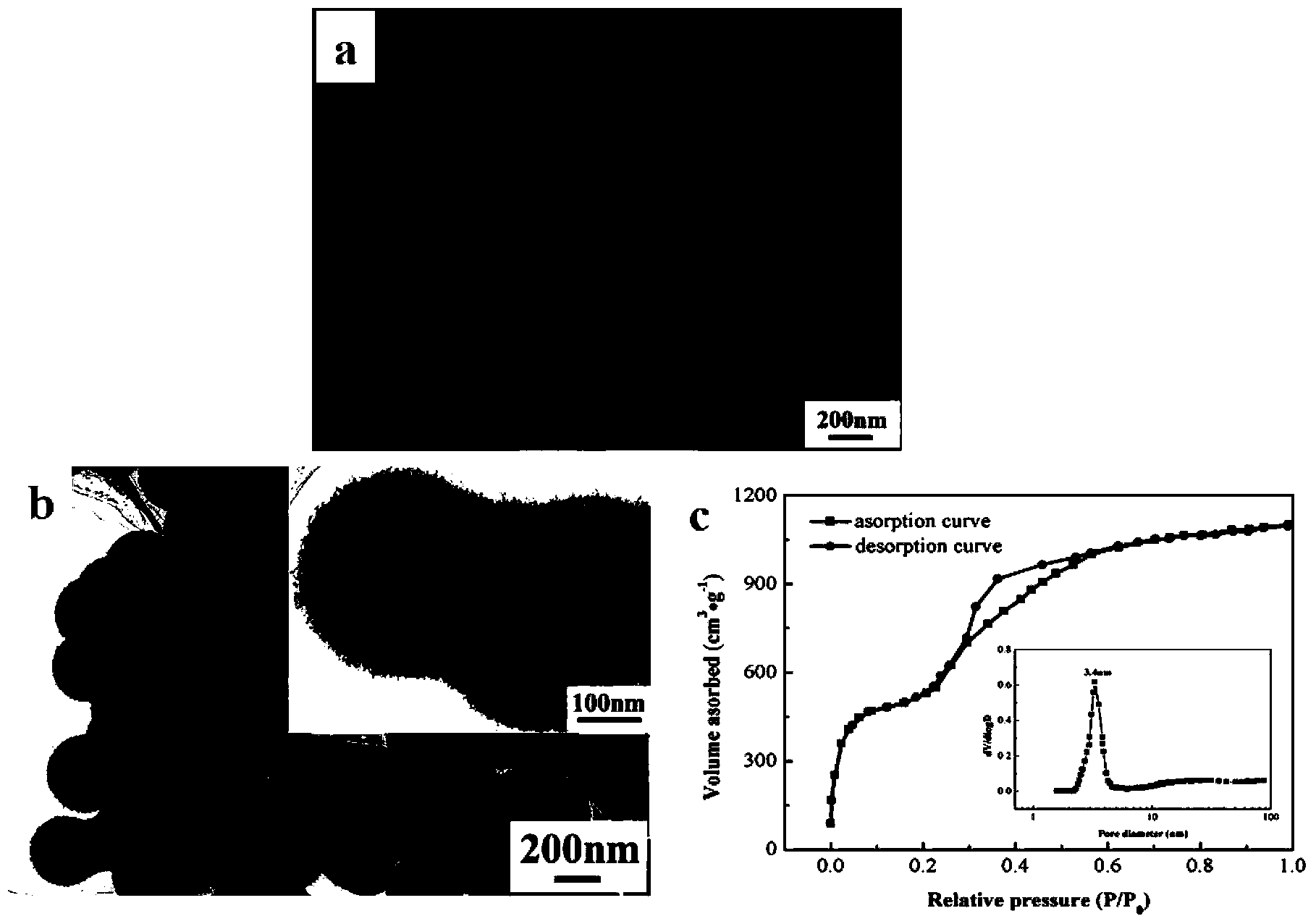

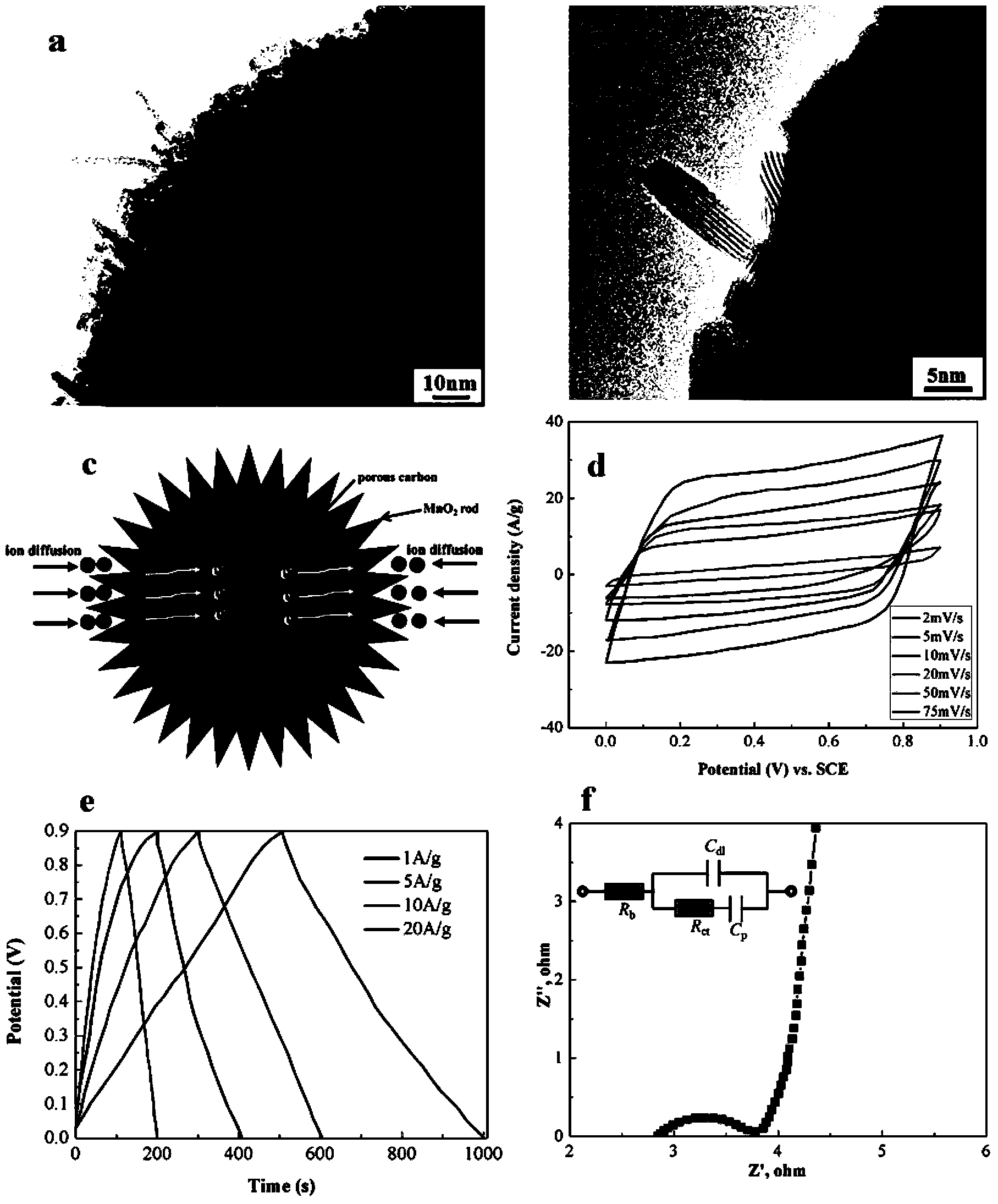

[0019] Step 1. Dissolve 60g of sucrose in 900mL of deionized water, stir until the solution is clear, transfer to a 1000mL hydrothermal reaction kettle, heat at 150°C and 900r / min for 6h, and the resulting precursor solution is centrifuged, washed with alcohol, After washing each 3 times, dry in a vacuum oven at 60°C for 12 hours to prepare monodisperse carbon spheres;

[0020] Step 2: Take 1g of monodisperse carbon spheres and heat them in 500mL of 0.5M NaOH solution. The heating temperature is 50°C and the heating time is 12h. Dry in a vacuum oven for 12 hours, and then calcinate the obtained solid in an argon atmosphere furnace, the calcining temperature is 1000°C, and the calcining time is 0.5h;

[0021] Step 3: Use the modified carbon spheres in step 2 as a template, place in 200mL, 5g / L KMnO 4 In the aqueous solution, stirred and aged at room temperature for 5 hours, a precipitate was obtained, and the precipitate ...

Embodiment 2

[0024] This embodiment includes the following steps:

[0025] Step 1. Dissolve 80g of fructose in 900mL of deionized water, stir until the solution is clear, transfer to a 1000mL hydrothermal reaction kettle, heat at 170°C and 900r / min for 3 hours, and then centrifuge, wash with water, and alcohol After washing each 3 times, dry in a vacuum oven at 60°C for 12 hours to prepare monodisperse carbon spheres;

[0026] Step 2: Take 1.5g of monodisperse carbon spheres and heat them in 200mL of 2M NaOH solution. The heating temperature is 70°C and the heating time is 8h. Dry in an oven for 15 hours, and then calcine the obtained solid in a vacuum furnace at a calcination temperature of 700°C and a calcination time of 2 hours;

[0027] Step 3. Use the modified carbon spheres in step 2 as a template, place in 500mL, 10g / L KMnO 4 In the aqueous solution, stirred and aged at room temperature for 4 hours, a precipitate was obtained, and the precipitate was centrifuged, washed with water...

Embodiment 3

[0030] This embodiment includes the following steps:

[0031] Step 1. Dissolve 100g of glucose in 900mL of deionized water, stir to a clear solution, transfer to a 1000mL hydrothermal reaction kettle, heat at 200°C and 900r / min for 3 hours; the resulting precursor solution is centrifuged, washed with water, and washed with alcohol After 3 times each, dry in a vacuum oven at 60°C for 12 hours to prepare C balls.

[0032] Step 2: Take 3g of dried C balls, heat and stir in 750mL, 5M NaOH solution at 80°C for 6h, then centrifuge the mixture solution, wash with water, wash with alcohol three times, and dry in a vacuum oven at 80°C for 12h. The obtained solid was then calcined in an argon atmosphere at a calcining temperature of 800° C. and a calcining time of 2 h.

[0033] Step 3. Use the carbon spheres modified in step 2 as a template, and place them in 800mL, 15g / L KMnO 4 In an aqueous solution, stir and age at room temperature for 1 h to obtain a precipitate, centrifuge the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com