Variable-blank-holding-force beam type drawing die

A drawing die and variable blank holder force technology, applied in the field of variable blank holder force beam drawing dies, can solve the problems of insufficient plastic deformation of parts, easy distortion of integral parts, uneven side walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

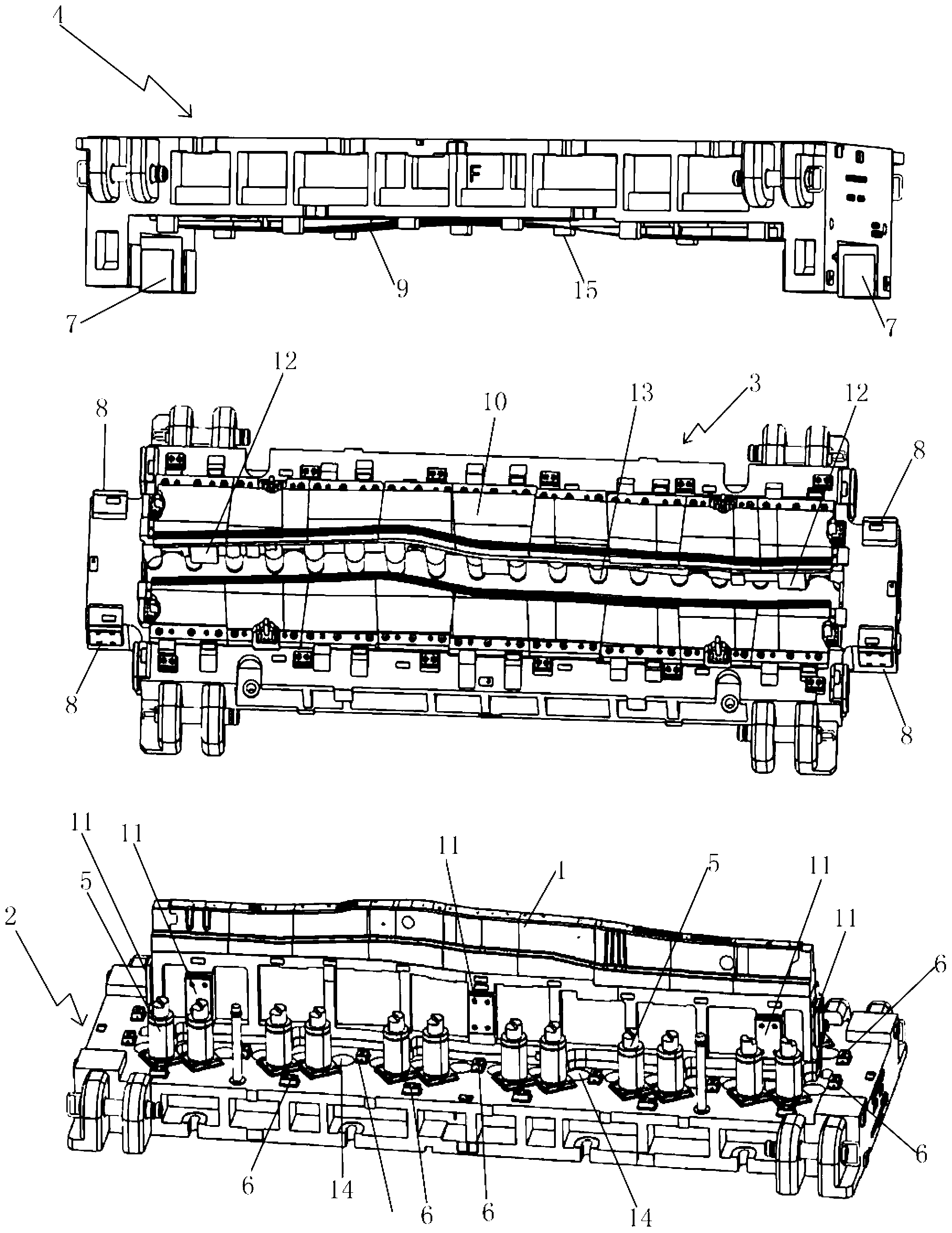

[0018] The following with attached figure 1 A variable blank holder force beam drawing die of the present invention will be further described in detail.

[0019] A variable blank holder force beam drawing die of the present invention, please refer to figure 1 , including the die base 4 and the punch base 2 arranged up and down and the blank holder assembly 3 arranged between the die base 4 and the punch base 2, the convex mold base 2 is provided with a raised Punch 1, at least two groups of nitrogen spring assemblies 5 are respectively arranged on the front and rear sides of the punch 1 on the punch seat 2, the top of the nitrogen spring assembly 5 is in contact with the lower surface of the blank holder assembly 3, The male die 1 is in contact with the blank holder assembly 3, and the lower surface of the die holder 4 is in contact with the upper surface of the blank holder. In this way, the mold moves on the press, and after the die contacts the binder surface 10 of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com